Robot pose error measuring system and method in Cartesian coordinate mode

A technology of error measurement and Cartesian coordinates, applied in the direction of measuring devices, measuring angles, instruments, etc., can solve the problems of expensive equipment, large workload, cumbersome data collection, etc., and achieve the effects of low development cost, improved efficiency, and convenient system maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

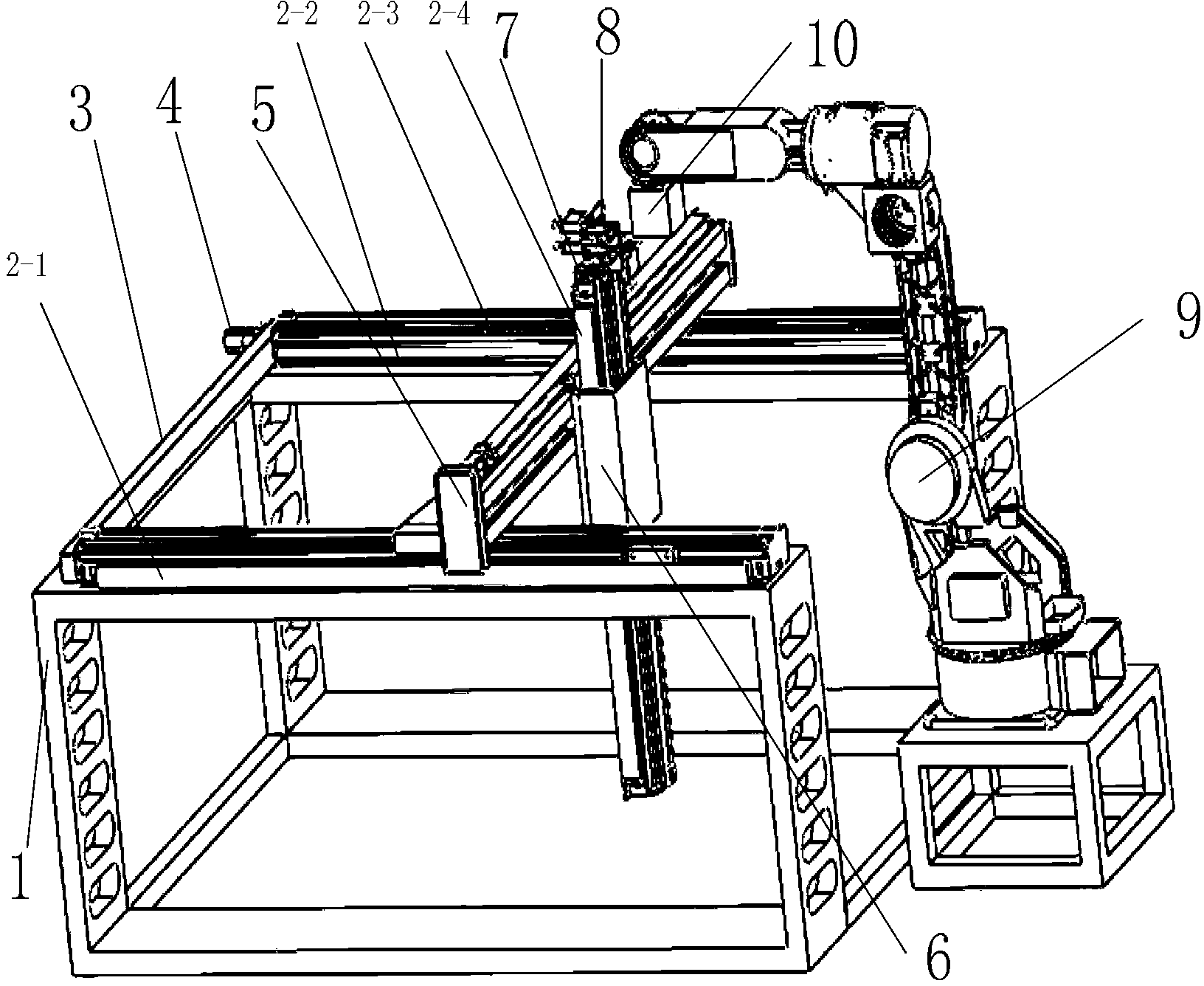

[0028] The present invention includes a frame 1 , a guiding unit, a driving unit, a measuring unit, a robot 9 and a workpiece 10 . Such as figure 1 As shown, the guide unit in this embodiment refers to four sets of linear guide rails, which are the first set of linear guide rails 2-1, the second set of linear guide rails 2-2, the third set of linear guide rails 2-3 and the fourth set of linear guide rails. Guide rails 2-4, each set of linear guide rails includes ball screws, sliders, baffles, buffer rubber sleeves, etc.; the drive unit includes belt transmission 3, reducer 5 and four AC servo motors 4; the measuring unit consists of six sets The laser displacement sensor 8 and a touch panel 7 constitute.

[0029] In this embodiment, the first and second sets of linear guide rails are installed horizontally on the frame 1, and the ball screws inside the first and second sets of linear guide rails are connected through the belt transmission device 3 at the end far away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com