Automatic polyester film roll palletizing system system with pneumatic shaft gripper

A polyester film and palletizing system technology, applied in the direction of object stacking, conveyors, conveyor objects, etc., can solve the problems of difficult to turn over, handling, low efficiency, and bulky volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

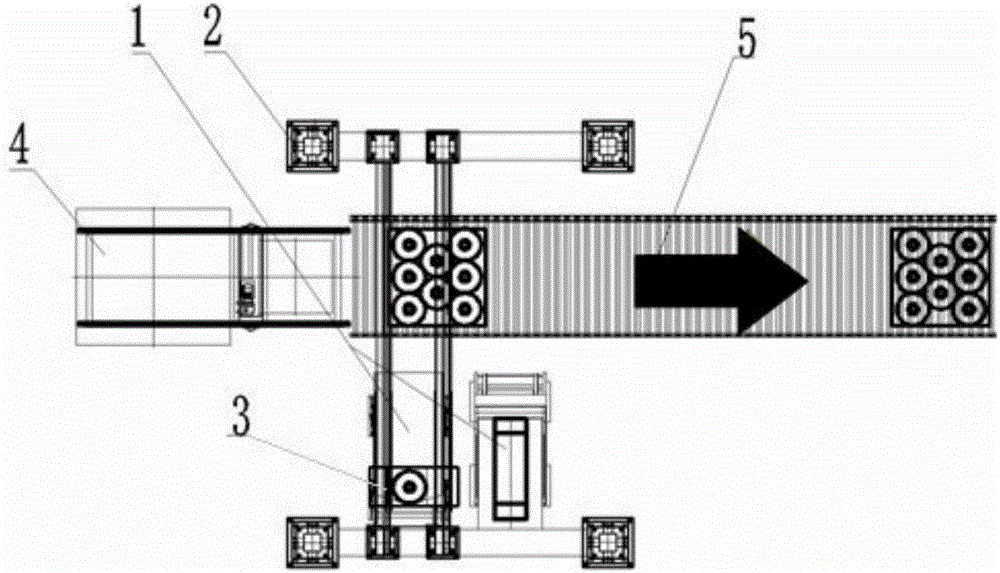

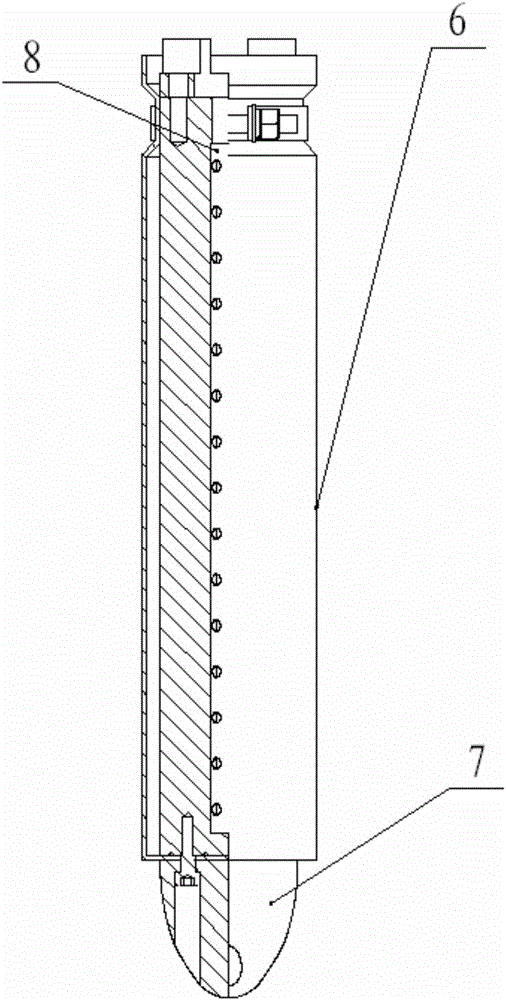

[0012] Such as figure 1 As shown, according to the present invention, the polyester film roll automatic palletizing system with an air shaft gripper includes: a turning machine 1, a Cartesian coordinate robot 2, an air shaft gripper 3, a pallet removal machine 4, and a conveyor line 5. Turning machine 1 turns over the polyester film roll delivered by the previous station by 90°; Cartesian coordinate robot 2 detects the position of the polyester film roll and positions it so that the gripper 3 of the air expansion shaft falls into the core of the polyester film roll At the designated position, the air source starts to inflate, so that the air bag 6 on the outside of the handle 3 of the air expansion shaft is inflated, and it is tightly attached to the inner wall of the polyester film roll core, and the friction between the two is used to grasp the polyester film. The film roll; the depalletizing machine 4 separates a pallet to the pallet conveying line 5; the rectangular coord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com