Corrugated paper board production line

A corrugated board and production line technology, applied in the field of corrugated board production, can solve the problems of poor stacking quality, loss of heat energy, simple structure, etc., and achieve the effects of improved stacking efficiency and quality, accurate temperature control, and convenient and fast loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

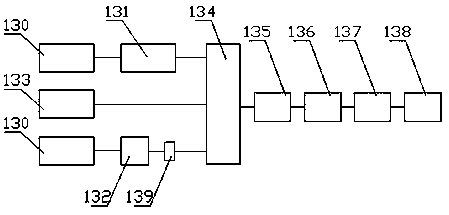

[0032] As shown in the drawings, the present invention includes a pair of base paper rack lifting arms 130, a tissue preheating mechanism 131, a lining paper preheating mechanism 132, a single corrugator 133, a laminator 134, a dryer 135, and a slitter 136 , Cross-cutting machine 137 and palletizer 138, a pair of base paper rack lifting arms 130 are respectively located at the paper feeding end of the paper preheating mechanism 131 and the inner paper preheating mechanism 132, the paper preheating mechanism 131, the inner paper preheating The paper output ends of the mechanism 132 and the single corrugator 133 are respectively located at the paper feed end of the laminator 134, and an automatic switching paper system 139 is provided between the inner paper preheating mechanism 132 and the laminator 134, and the dryer 135 The paper feed end is located at the paper output end of the laminator 134, the paper feed end of the slitter 136 is located at the paper output end of the drye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com