Mechanical arm tool coordinate system self-calibration method

A tool coordinate system, robotic arm technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as difficult parameters, determination, and limitation of robot applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be pointed out that the following is a further detailed description of the present invention in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention and should not be regarded as having any limiting effect on the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

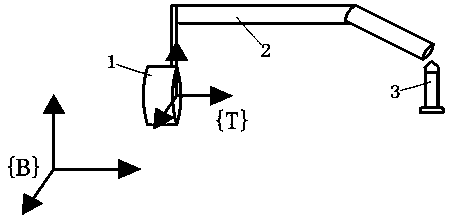

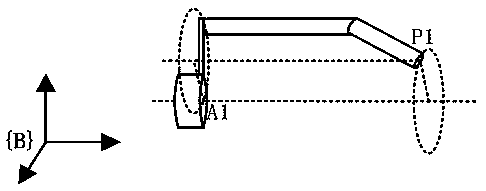

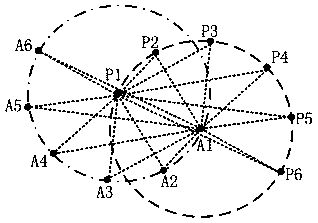

[0030] see Figure 1 to Figure 2 , a self-calibration method for a tool coordinate system of a manipulator provided in a preferred embodiment of the present invention, comprising the following steps:

[0031] (1) Fix and install the tool 2 on the rotating shaft 1 at the end of the mechanical arm, and return the rotating shaft 1 equipped with the tool 2 to zero, at this time, bring the top 3 close to the center point of the end of the tool 2 until it coincides , fix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com