Double-speed retractable positioning system

A telescopic positioning, double-speed technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of increased product cost, high equipment cost, long occupation time, etc., to improve service life, reduce production costs, and shape beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

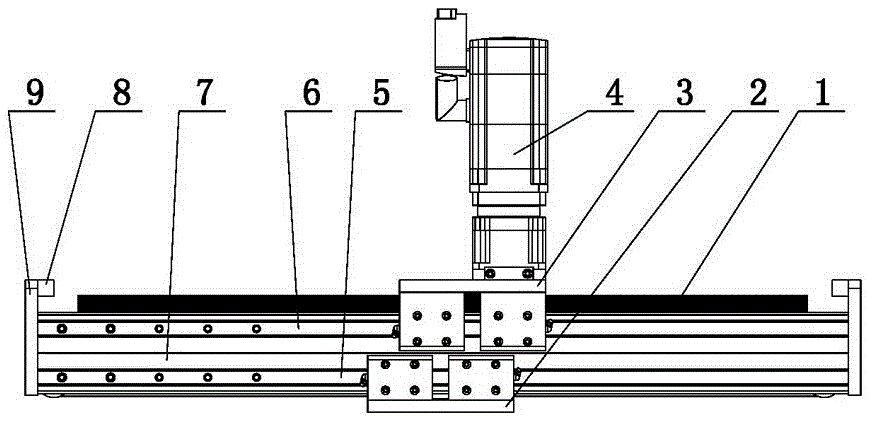

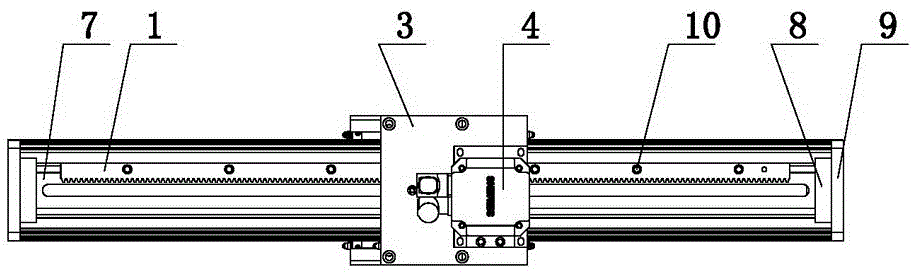

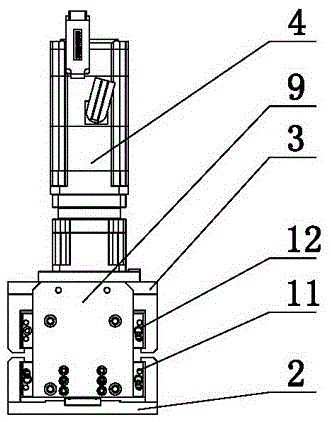

[0021] The present invention includes a load beam 7, which is characterized in that: the load beam 7 is provided with an upper slide plate 3, the upper slide plate 3 is provided with a driving device 4, and the drive device 4 meshes with the rack 1 on the load beam 7 through a driving gear 17; The lower part of the load beam 7 is provided with a synchronous belt annular mechanism 13, the upper slide plate 3 is connected to the top of the synchronous belt annular mechanism 13, and the bottom of the synchronous belt annular mechanism 13 is connected to a lower plate 2; the load beam 7 The length is 1000mm.

[0022] As a preferred solution of the present invention, upper positioning guide rails 6 are provided on both sides of the load beam 7 , and upper sliders 12 that cooperate with the upper positioning guide rails 6 are provided on the upper sliding plate 3 .

[0023] As another preferred solution of the present invention, lower positioning guide rails 5 are provided on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com