Rectangular coordinate robot screw driving manipulator and rectangular coordinate robot applying same

A Cartesian coordinate and robot technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision, inability to realize automatic nail feeding, slow efficiency, etc., and achieve accurate screw-in position, simple and reliable initial positioning, Easy suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

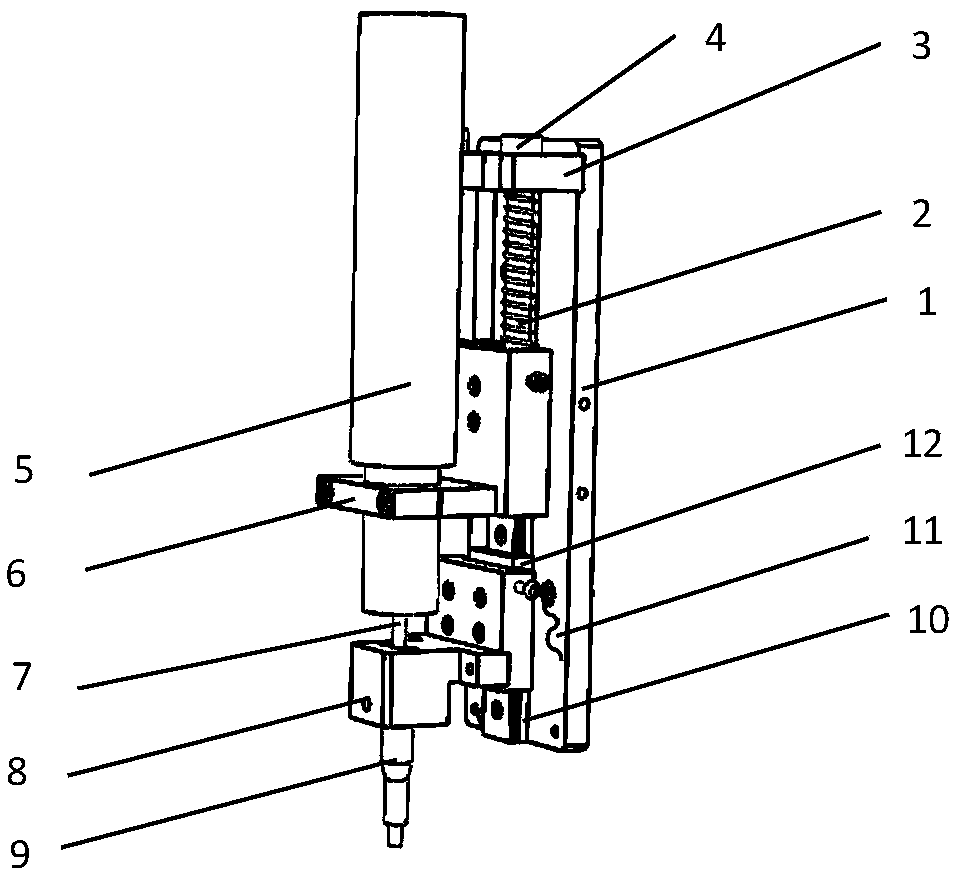

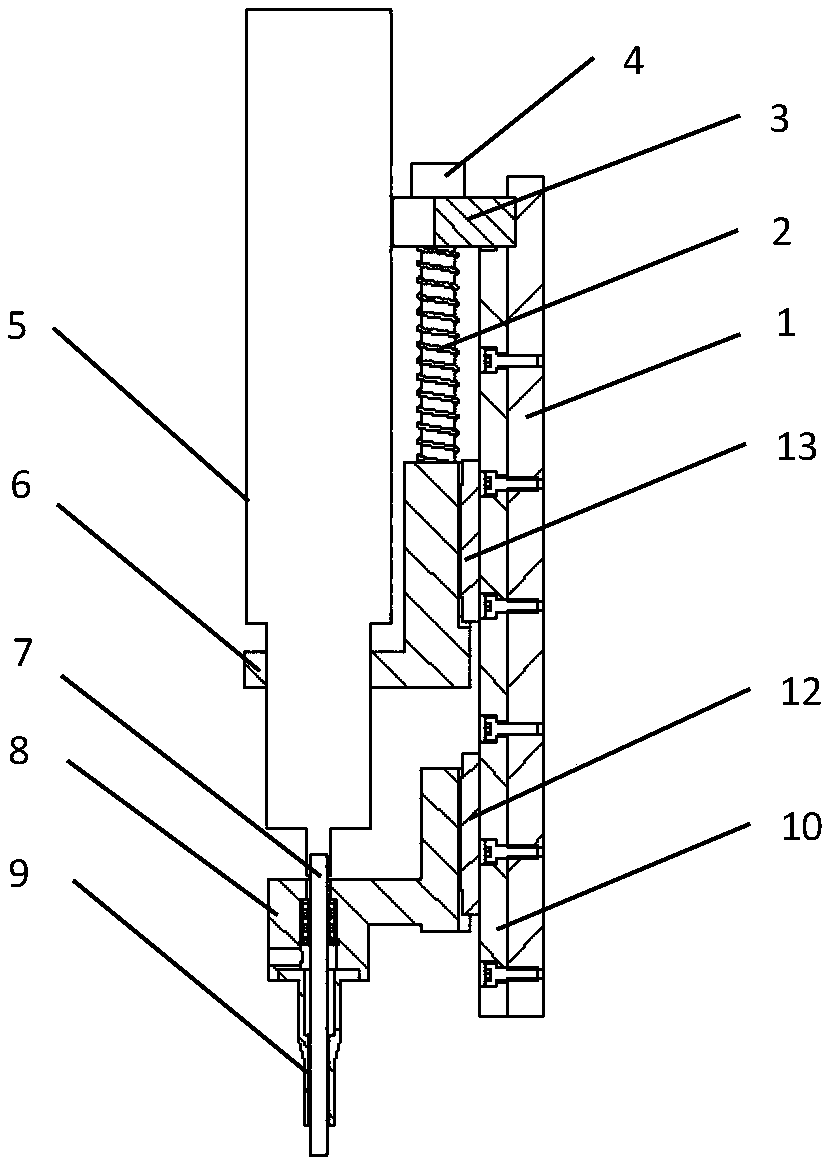

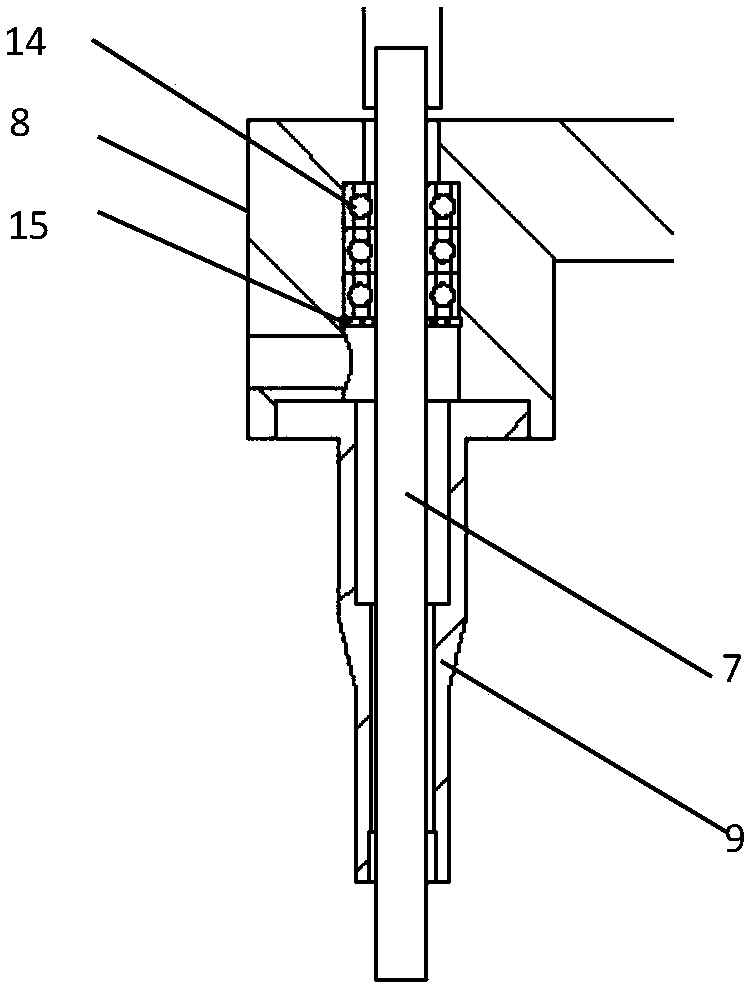

[0016] Such as figure 1 , figure 2 As shown, a Cartesian coordinate robot screwing manipulator includes an output end on which an electric batch jig is fixed. The jig includes a bottom plate 1, an electric batch clamping seat 6, a suction nozzle mounting seat 8, and a linear slide rail 10. Installed vertically on the base plate 1, the first slider 13 is used in conjunction with the linear slide rail 10, the first slider 13 can slide along the linear slide rail 10, the electric batch clamping seat 6 is fixed on the first slider 13, and the electric batch The batch clamping seat 6 is used to clamp the electric batch 5, one end of the first spring 2 is in contact with the bottom plate 1, the other end of the first spring 2 is in contact with the electric batch clamping seat 6, and the second slide rail 13 is in contact with the linear slide rail 10 Used together, the second slide rail 13 can slide along the linear slide rail 10, the second slide block 13 is connected to one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com