Machine vision system based industrial robot

A machine vision system and industrial robot technology, applied in the field of robotics, can solve problems such as lack of environmental perception and adaptability, and limited robot applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

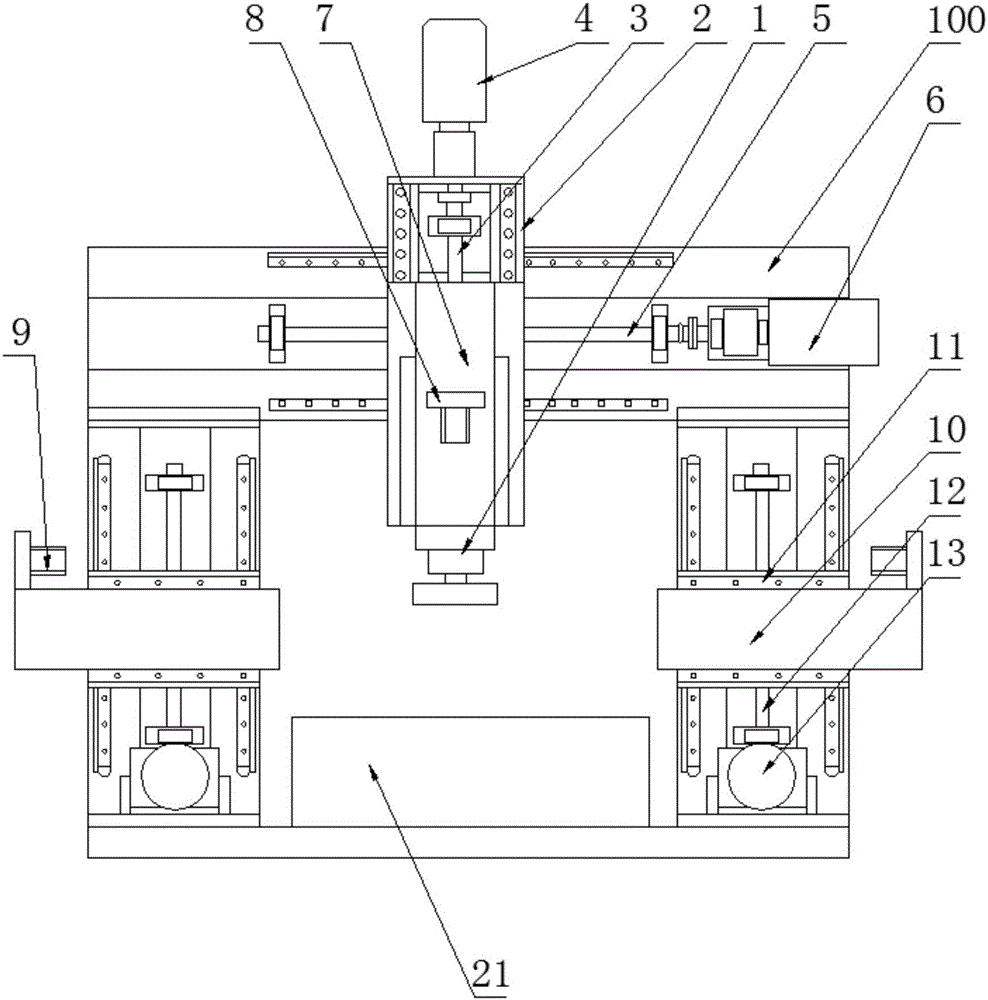

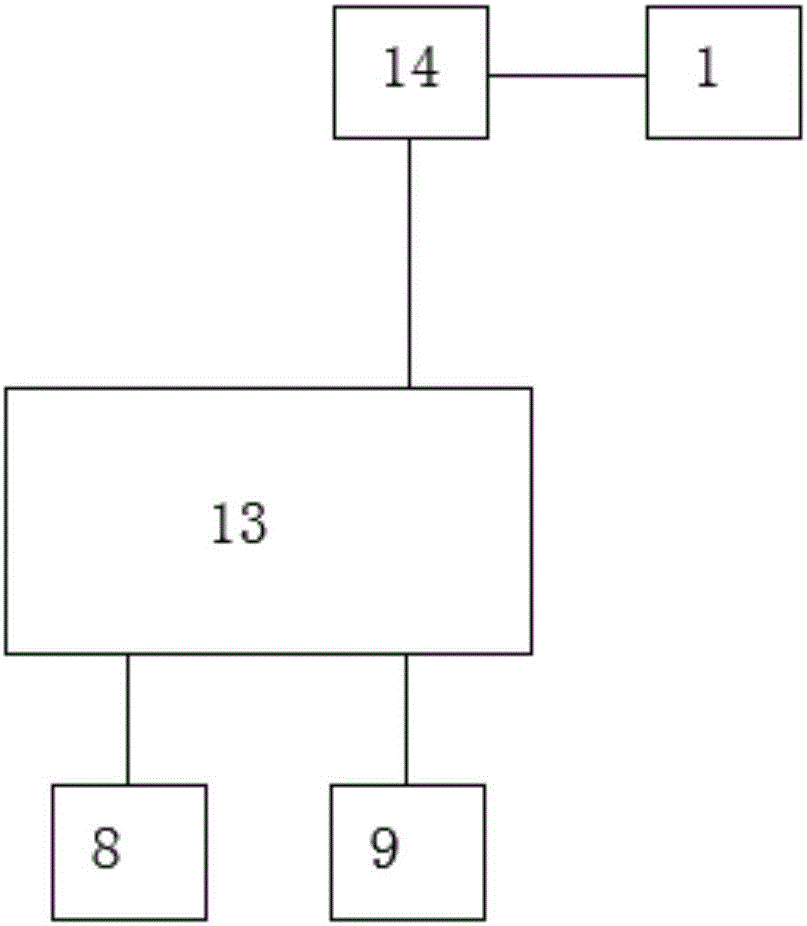

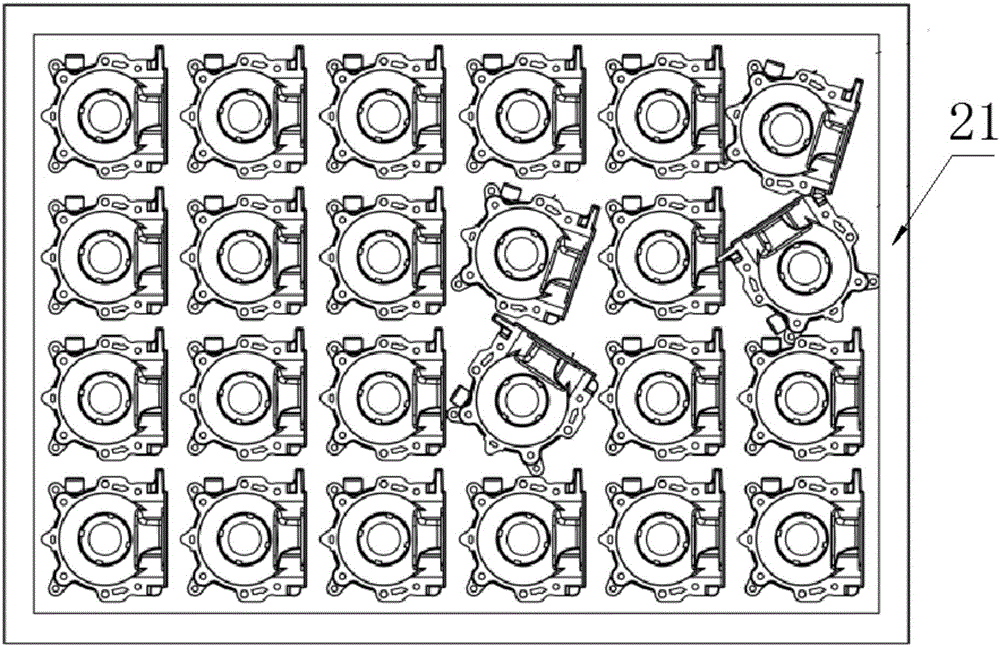

[0015] Attached below Figure 1-3 An embodiment of the present invention is described.

[0016] An industrial robot based on a machine vision system, including a Cartesian coordinate robot and a machine vision system. The milling head mechanism includes a grasping mechanism 1, a vertical sliding seat 2, a vertical lifting mechanism, and a traverse mechanism. The top is connected with a vertical lifting mechanism, the vertical lifting mechanism includes a vertical lifting screw 3, the grasping mechanism 1 is connected to the vertical lifting screw 3 through a nut base, and the top of the vertical lifting screw 3 is connected to the vertical sliding through a coupling The vertical lifting servo motor 4 on the top of the base 2. The grasping mechanism 1 is installed on the vertical lifting linear rail on the vertical sliding base 2 through a sliding block. The lower front side of the vertical sliding base 2 is provided with a sliding base cover 7 , The rear side of the vertical sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com