Automatic feeding and discharging device for cylindrical workpieces

An automatic loading and unloading, cylindrical technology, used in loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problems of dangerous manual operation, low efficiency, long process processing time, etc., to reduce the space occupied by equipment, The effect of increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

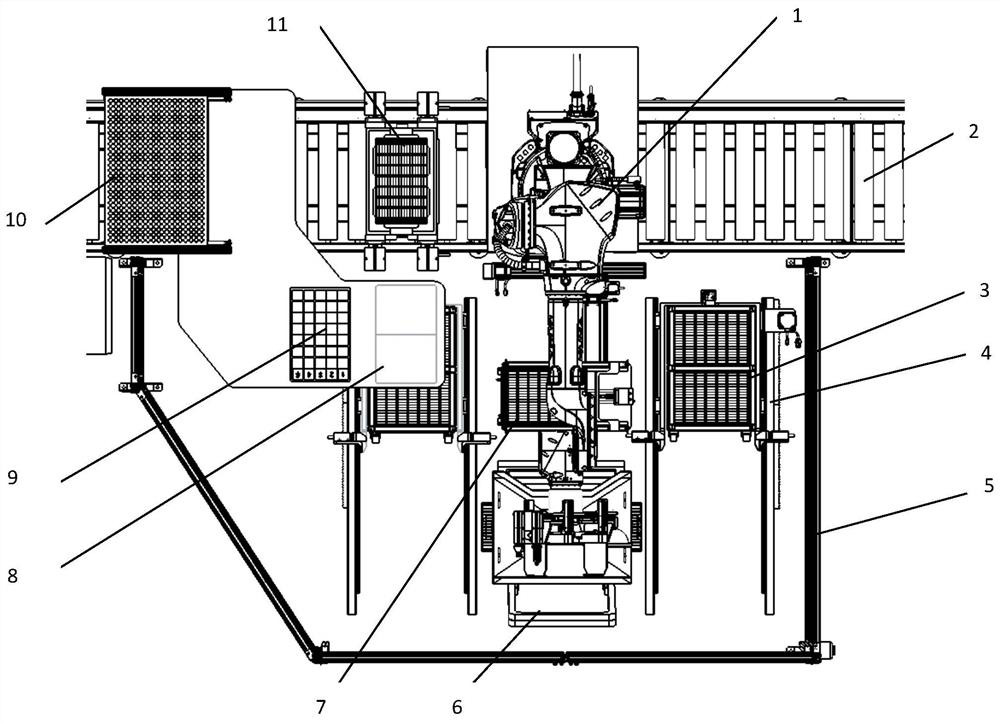

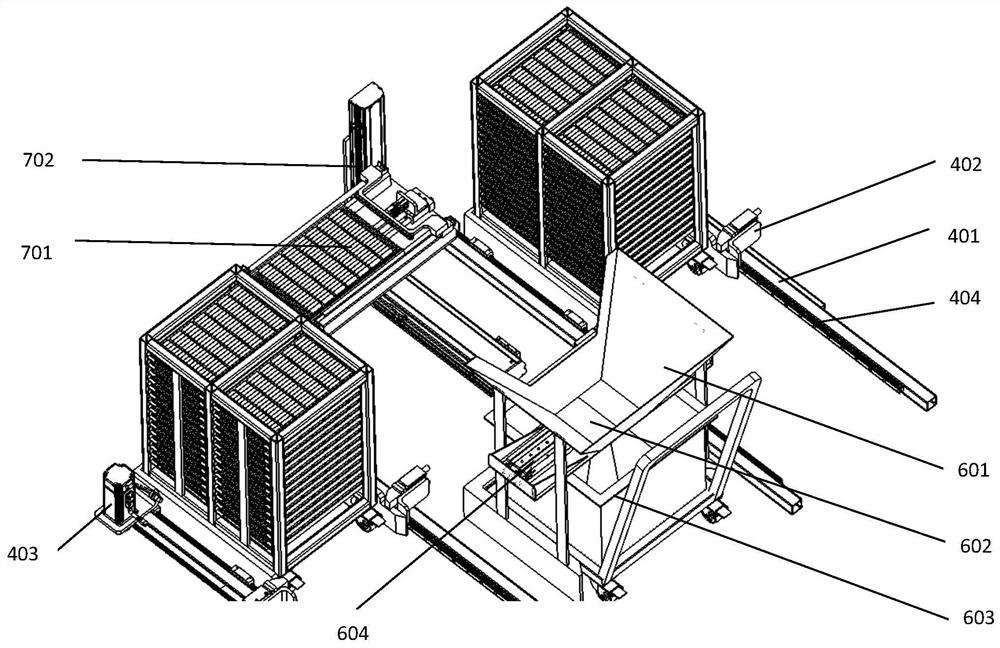

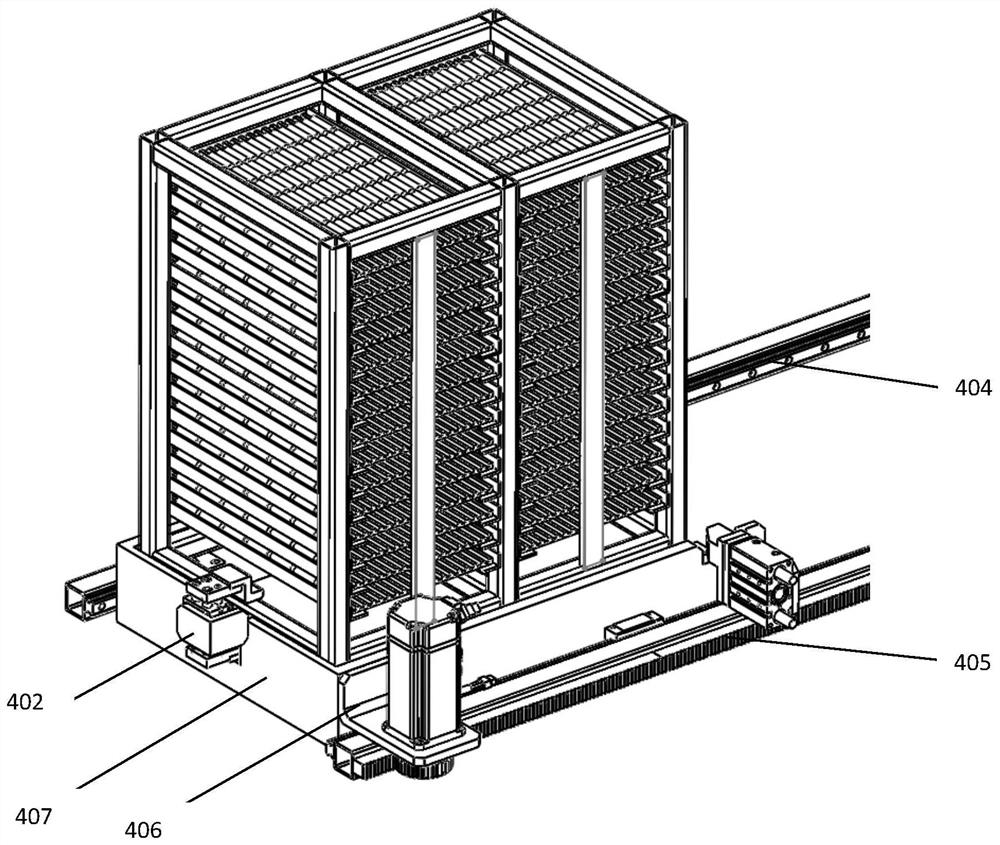

[0023] Such as Figure 1-Figure 8 As shown, an automatic loading and unloading device for cylindrical workpieces includes a handling robot 1, and a tray rack feeding unit, a carbon box placement platform 8, a circulating conveyor line 2, a kiln, and a tray rack feeding unit are arranged in sequence around the handling robot 1 Including the pallet transfer manipulator 7 and the pallet rack 3, the transfer robot 1 transports materials between the circular conveyor line 2, the pallet transfer manipulator 7 and the carbon box placement table 8, and the pallet carrying the cylindrical workpiece is placed on the pallet rack 3, and the pallet transfer The manipulator 7 includes a three-dimensional rectangular coordinate robot body 702 and a pallet transfer gripper 701. The pallet transfer gripper 701 includes a gripper base plate 716, a push plate 712 and a pallet clamping unit 715. At the output end, guide grooves 711 are set on both sides of the gripper base plate 716. The channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com