Brushless motor outer rotor assembly with simple structure

A brushless motor, simple structure technology, applied in the direction of the casing/cover/support, magnetic circuit shape/pattern/structure, electrical components, etc., can solve the cage machining accuracy requirements, low production and installation efficiency, cage Complex installation and other problems, to achieve the effect of improving production and processing efficiency, convenient processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

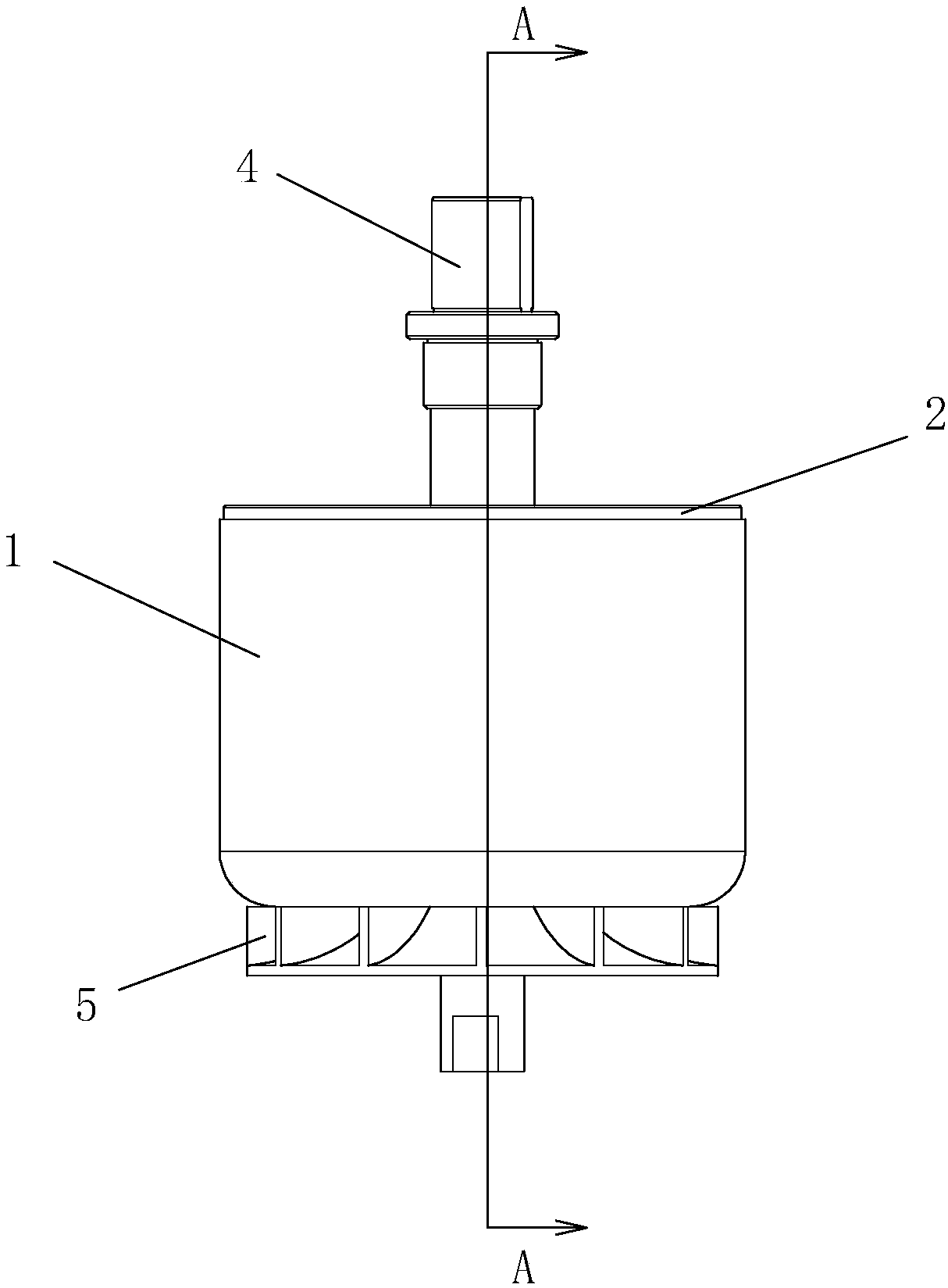

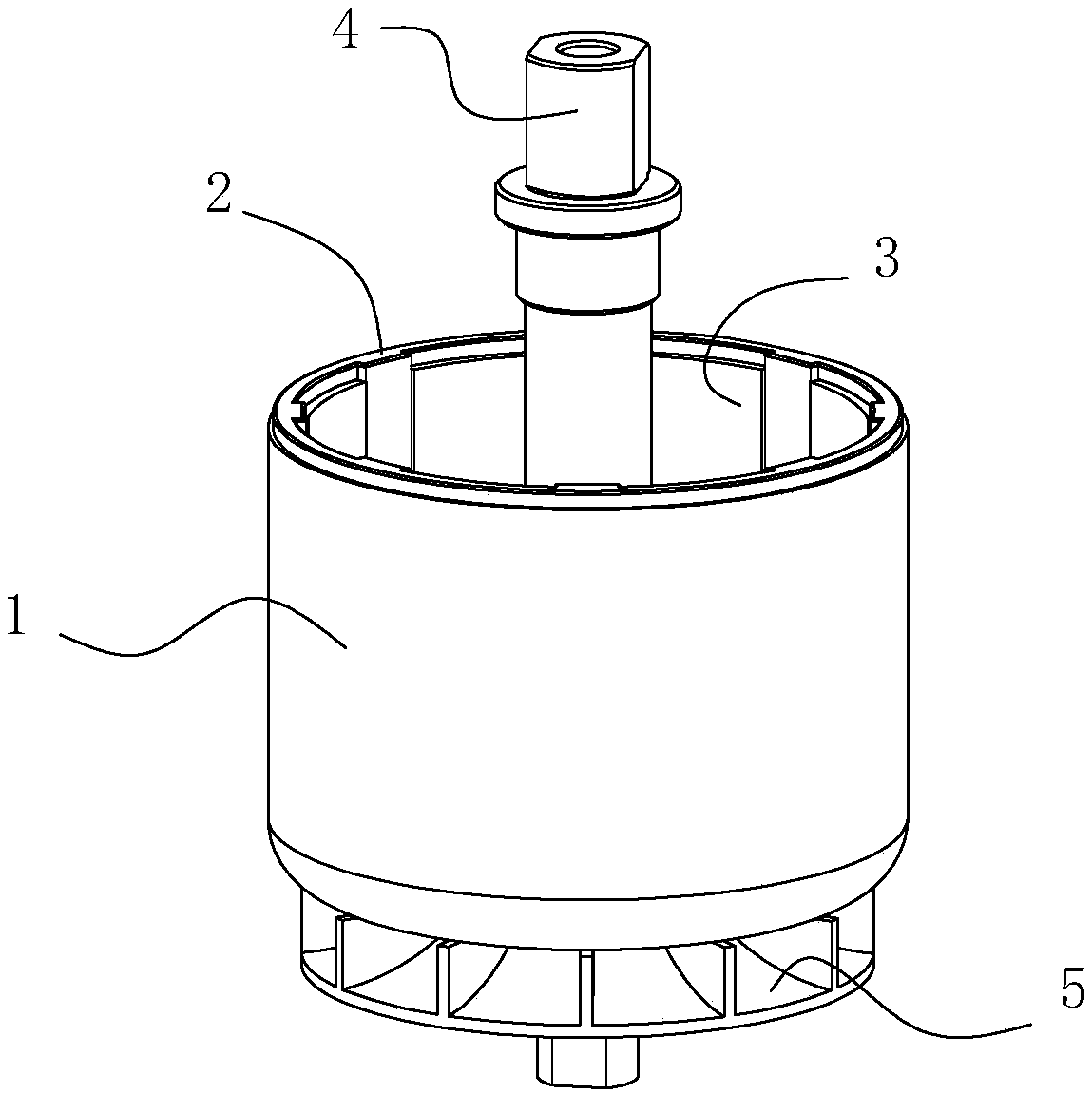

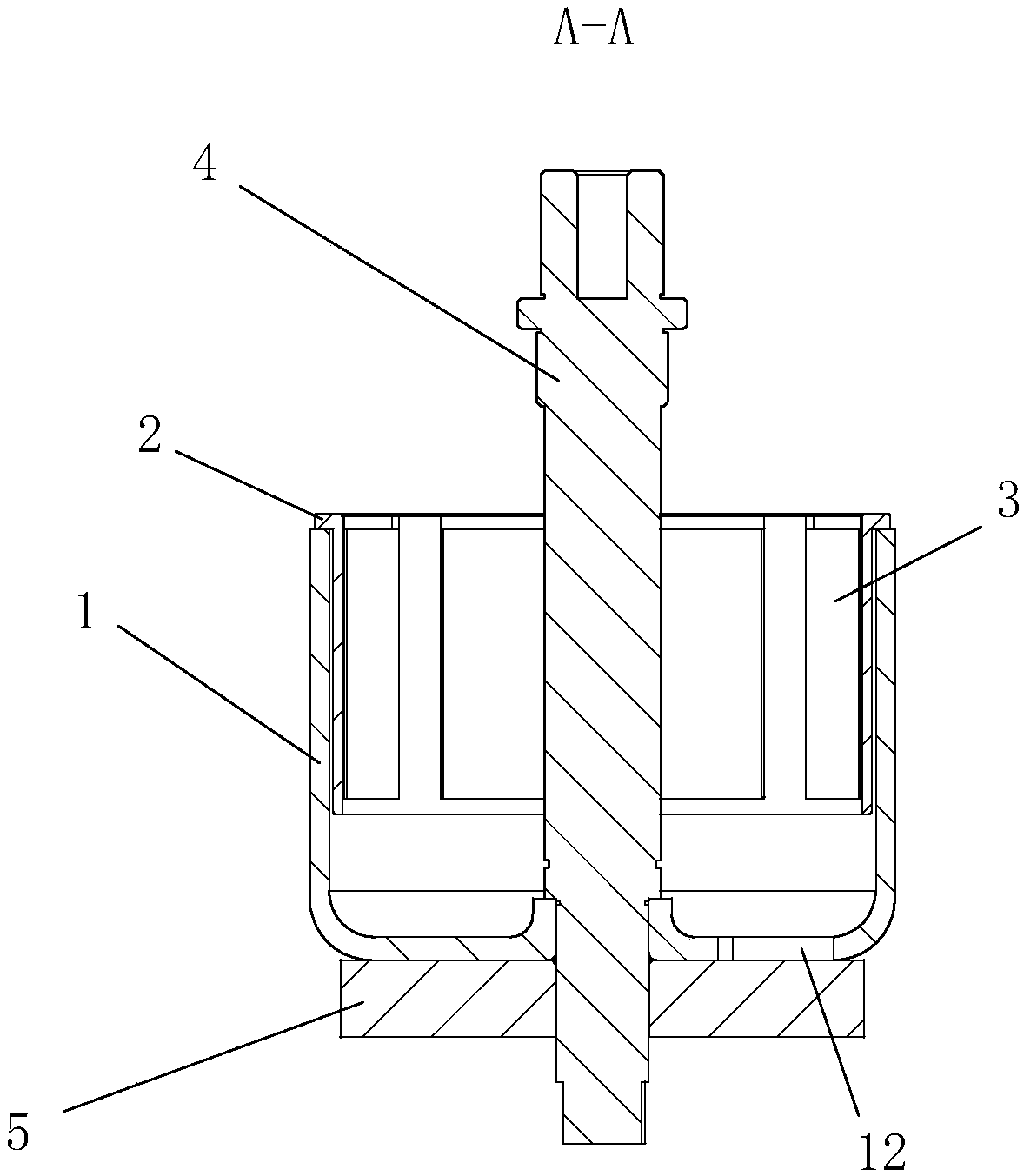

[0030] See Figure 1 to Figure 3 , The brushless motor outer rotor assembly with a simple structure of the present invention includes a motor housing 1 , a cage 2 , a permanent magnet 3 , a drive shaft 4 and fan blades 5 .

[0031] See figure 2 , image 3 , Figure 5 and Image 6 , The motor casing 1 is an integral piece made of iron or low carbon steel, and the motor casing 1 of this embodiment is made of 20 steel. The motor casing 1 is a casing with an upward opening, and the wall thickness of the motor casing 1 is 2 mm to 6 mm (3 mm in this embodiment). The center of the bottom of the motor housing 1 is provided with a shaft hole 11 that runs through it. The shaft hole 11 is formed by punching and stretching. The axial depth of the shaft hole 11 should be 4 mm to 8 mm (6 mm in this embodiment). The bottom of the motor casing 1 is provided with a set of cooling holes 12 running through it. The cooling holes 12 are arranged around the shaft hole 11 .

[0032] See Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com