Drawbar type inclined cutting machine having better heat dissipation effect

A technology of oblique cutting machine and pull rod type, which is applied in the direction of electromechanical devices, metal sawing equipment, metal processing machinery parts, etc., can solve the problems of high processing accuracy requirements for cages, low production and installation efficiency, and complicated cage installation, etc., to achieve The effects of reduced long-distance transportation, convenient transportation, and enhanced portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

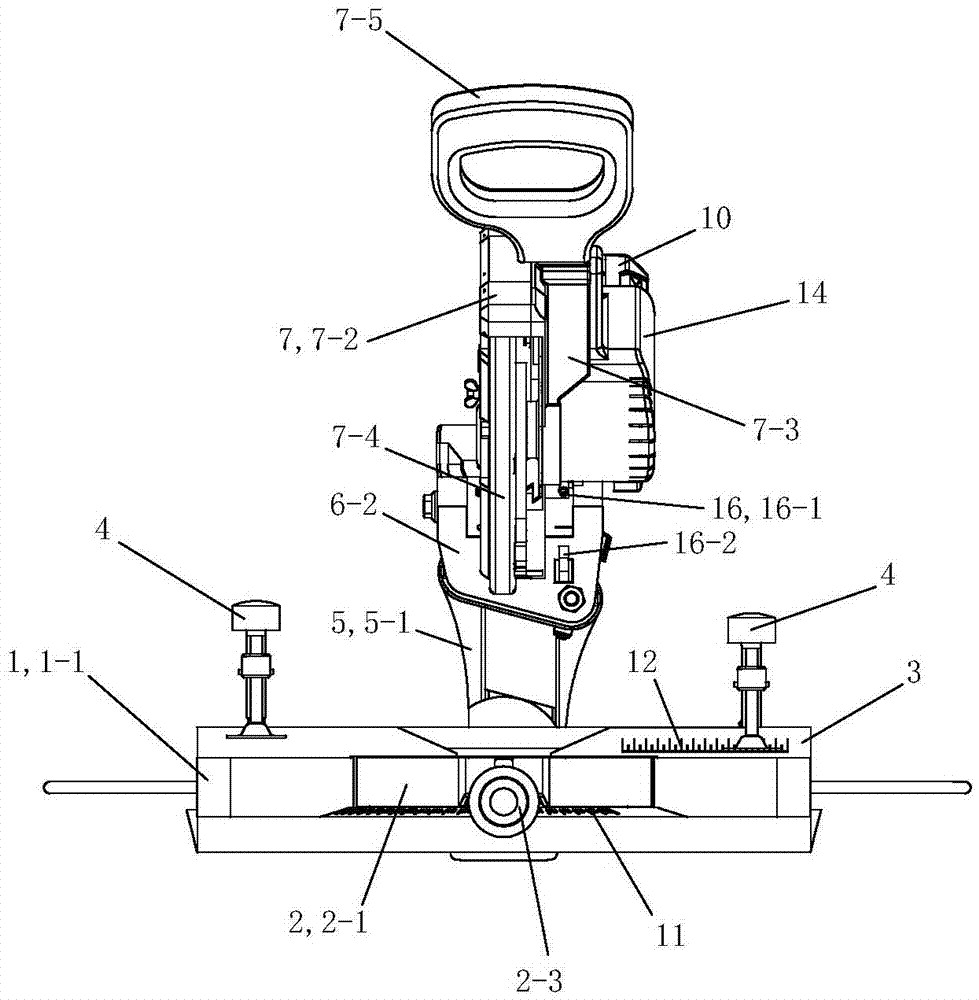

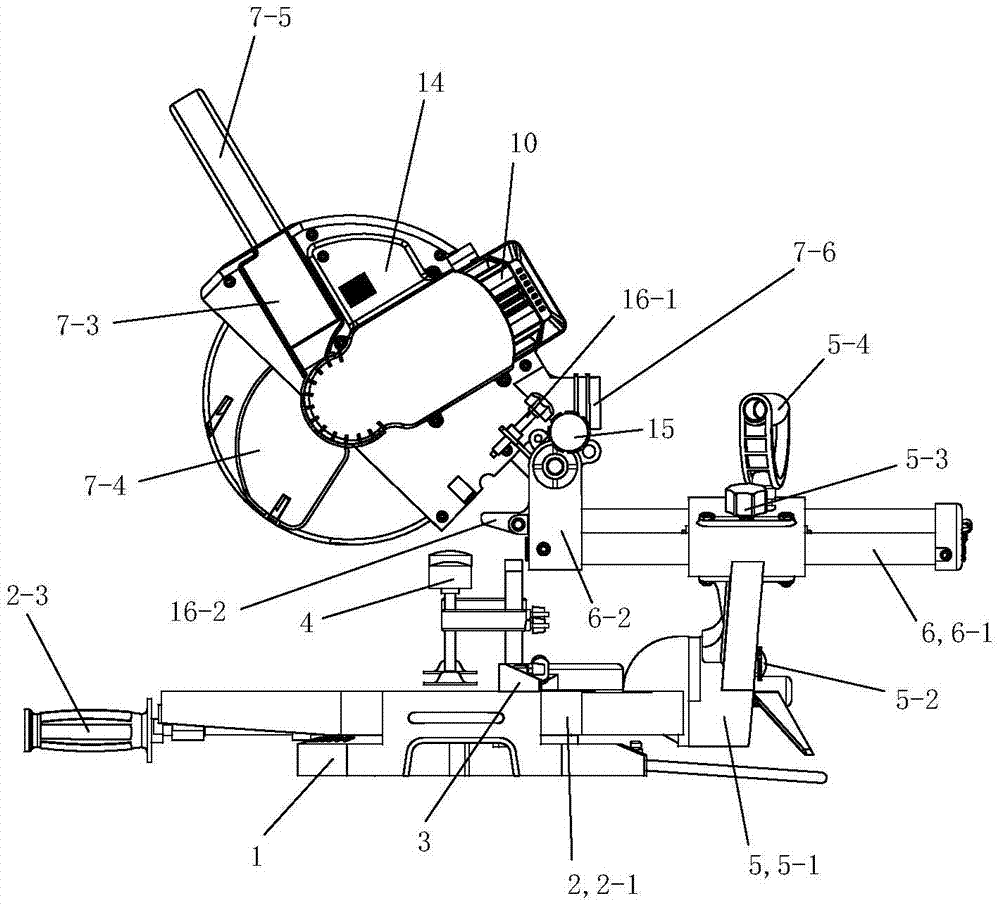

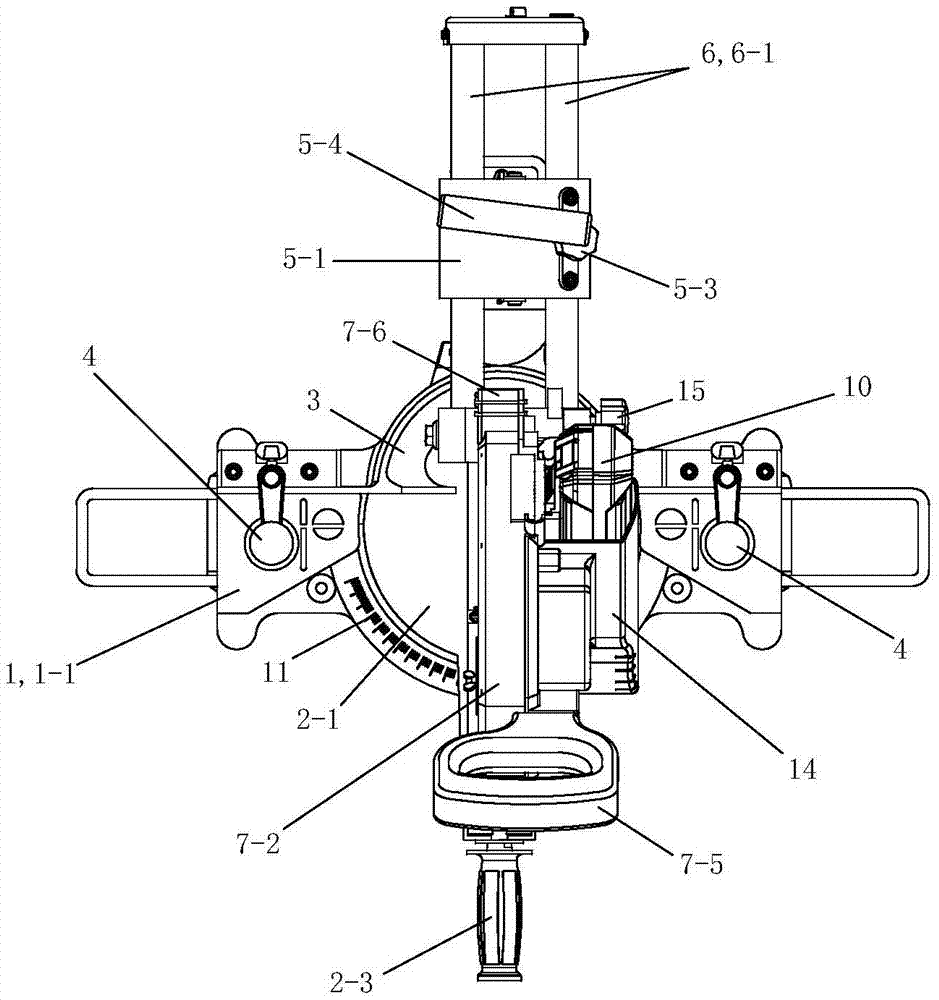

[0057] See Figure 1 to Figure 10 , the better heat dissipation rod-type bevel cutting machine of the present invention includes a base 1, a workbench 2, a support 3, a pressing device 4, a rocker arm 5, a slide bar assembly 6, a fuselage 7, a driving device 8, and a control device 9 , battery 10, saw blade 13, dust cover 14, body positioning device 15 and depth adjustment device 16.

[0058] See Figure 1 to Figure 10 , the base 1 is one piece. On the left and right sides of the base 1 are provided upwardly protruding supporting parts 1-1. An angle ruler 11 is provided on the front side of the middle part of the base 1 .

[0059] See Figure 1 to Figure 10 , The workbench 2 includes a turntable 2-1, a guard plate 2-2 and a workbench adjustment assembly 2-3. The turntable 2-1 of the workbench 2 is rotatably arranged on the base 1, between the support parts 1-1 on the left and right sides of the base 1, and the upper surface of the turntable 2-1 is at the same level as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com