Bone cement filling balloon structure

A bone cement and balloon technology, applied in the field of medical devices, can solve problems such as being unsuitable for minimally invasive surgery, incapable of filling bone cement, and difficult to operate with a balloon, so as to improve the efficiency and success rate of surgery, shorten the operation time, inject The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

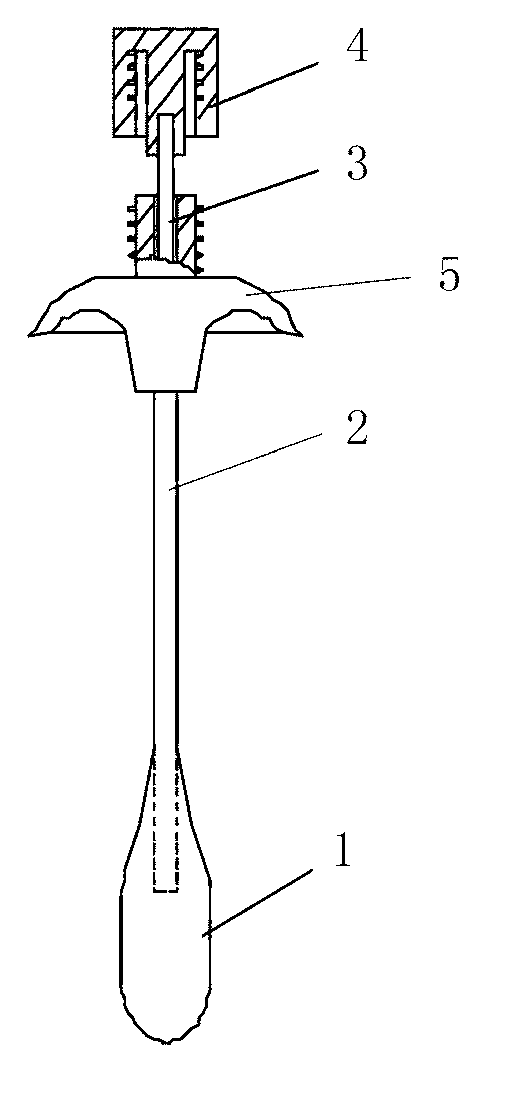

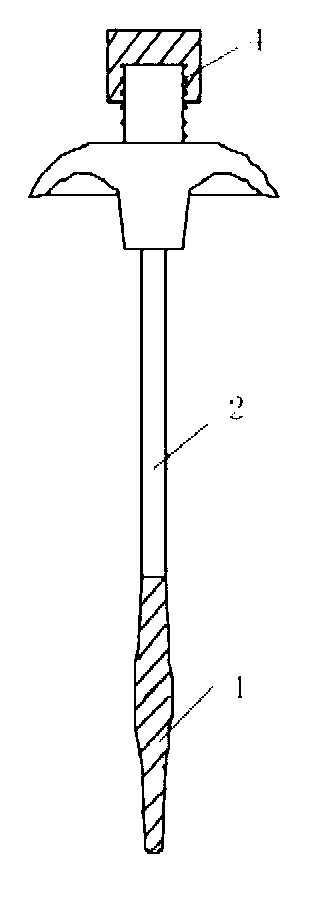

[0031] Using poly DL lactic acid (molecular weight: 50,000) as a raw material, the balloon 1 was prepared by electrospinning, with a thickness of 0.2 mm, a volume of 3 ml, and a handle diameter of 3.5 mm. Holes with a diameter of about 0.01 mm are evenly distributed on the surface of the balloon. The open end of the absorbable balloon 1 is connected to the outer or inner surface of the injector 2 away from the handle end, and the length of the injector 2 is 60 mm. Insert the balloon preloading rod 3 from the interface of the injector 2 that has been connected to the absorbable balloon 1 until the balloon is fully stretched, rotate the preloading rod until the balloon is fully attached to the balloon preloading rod, and the balloon The preloading rod is locked with the locking mechanism 4 on the handle 5 of the injector.

Embodiment 2

[0033] Pass the absorbable balloon device of Example 1 through the working tube with a diameter of 4 mm and a length of 100 mm, so that the balloon is completely exposed outside the working tube, loosen the locking device on the pre-installed rod, reversely rotate and take out the pre-installed rod. Prepare bone cement PMMA10ml, inhale a sufficient amount of bone cement into the external syringe with pressure display after 20s, and then connect it to the interface of bone cement injector 2, inject slowly until the pressure shows 0.5kgf / cm when the added amount is 4ml 2, There is no leakage on the surface of the balloon, and the balloon is not ruptured. After the bone cement solidifies, hold the balloon filled with bone cement with your hand, turn the handle of the injector lightly to disconnect the absorbable balloon filled with bone cement from the injector, and pull out the injector.

Embodiment 3

[0035] Using L lactic acid-glycolic acid copolymer as raw material (molecular weight 80,000), the balloon 1 was prepared by electrospinning, with a thickness of 0.15 mm, a volume of 8 ml, and a handle diameter of 3.2 mm. A laser drilling machine is used to form dozens of holes 6 with a diameter of about 1.0 mm on the surface of the balloon. The open end of the absorbable balloon 1 is connected to the outer or inner surface of the injector 2 away from the handle end, and the length of the injector 2 is 220 mm. Insert the balloon preloading rod 3 from the interface of the injector 2 that has been connected to the absorbable balloon 1 until the balloon is fully stretched, rotate the preloading rod until the balloon is fully attached to the balloon preloading rod, and the balloon The preloading rod is locked with the locking mechanism 4 on the handle 5 of the injector. Inject the bone cement in the same manner as in Example 2 until the pressure shows 0.8kgf / cm when the amount add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com