Composite bone repair material with light display effect and self-positioning function and preparation method thereof

A self-positioning, bone repair technology, applied in the field of biomedical engineering, can solve problems such as increasing the complexity of the manufacturing process, achieve the effect of good biomechanical matching performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a polyamino acid composite bone repair material with a light effect and a self-positioning function, comprising the following steps:

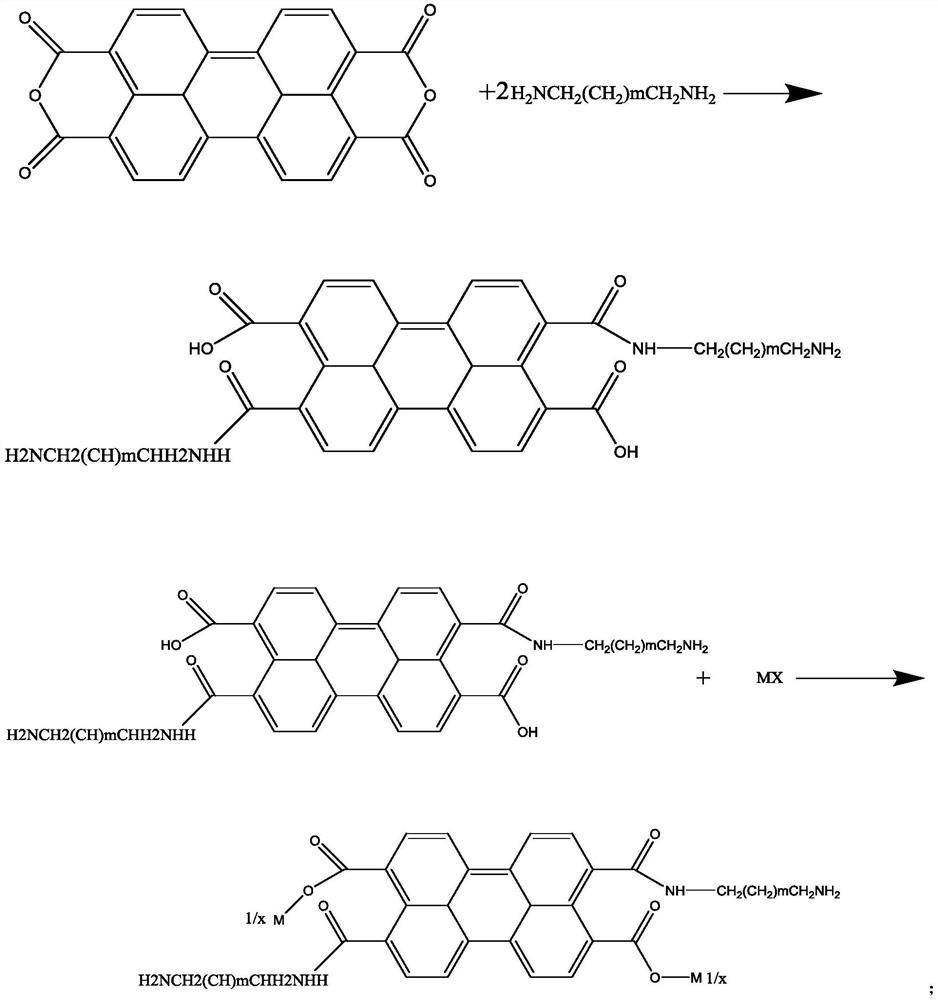

[0041] (1) 3,4,9,10-perylenetetracarboxylic acid diamide (I) with double amino terminal is reacted with 3,4,9,10-perylenetetracarboxylic dianhydride and aliphatic diamine, and then reacted with lanthanum System elements react to form 3,4,9,10-perylenetetracarboxylic acid diamide diacid salt (II) with light effect; 3,4,9,10-perylenetetracarboxylic acid diamide diacid salt (II) The photoelectric effect of the ring structure cooperates with the photoelectric effect of lanthanide ions, which can emit light at a certain wavelength or block X-rays to form an image, so that it has the positioning function of the material under light and radiation; the specific reaction formula is as follows:

[0042]

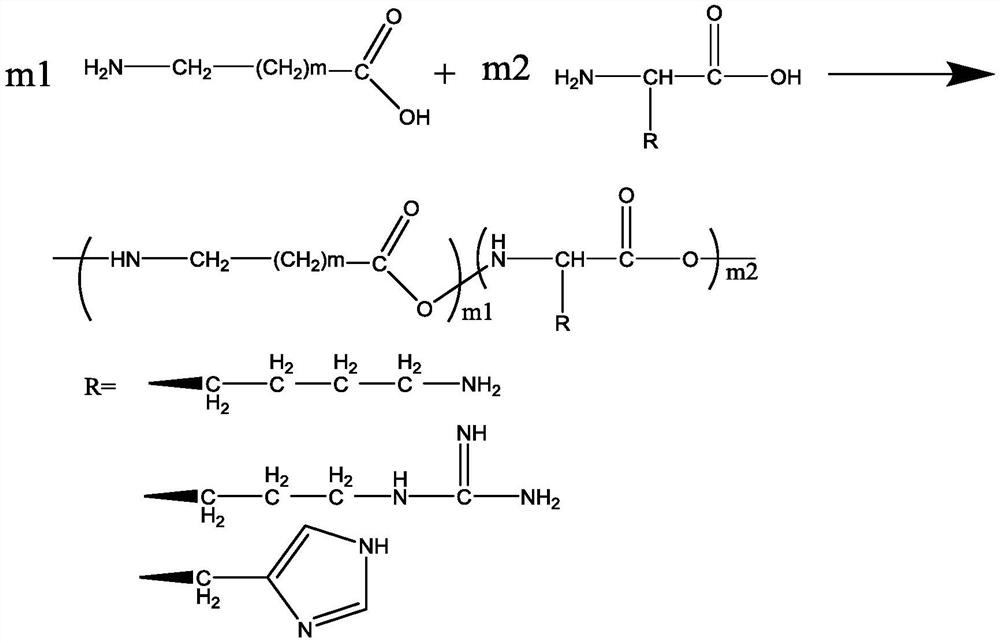

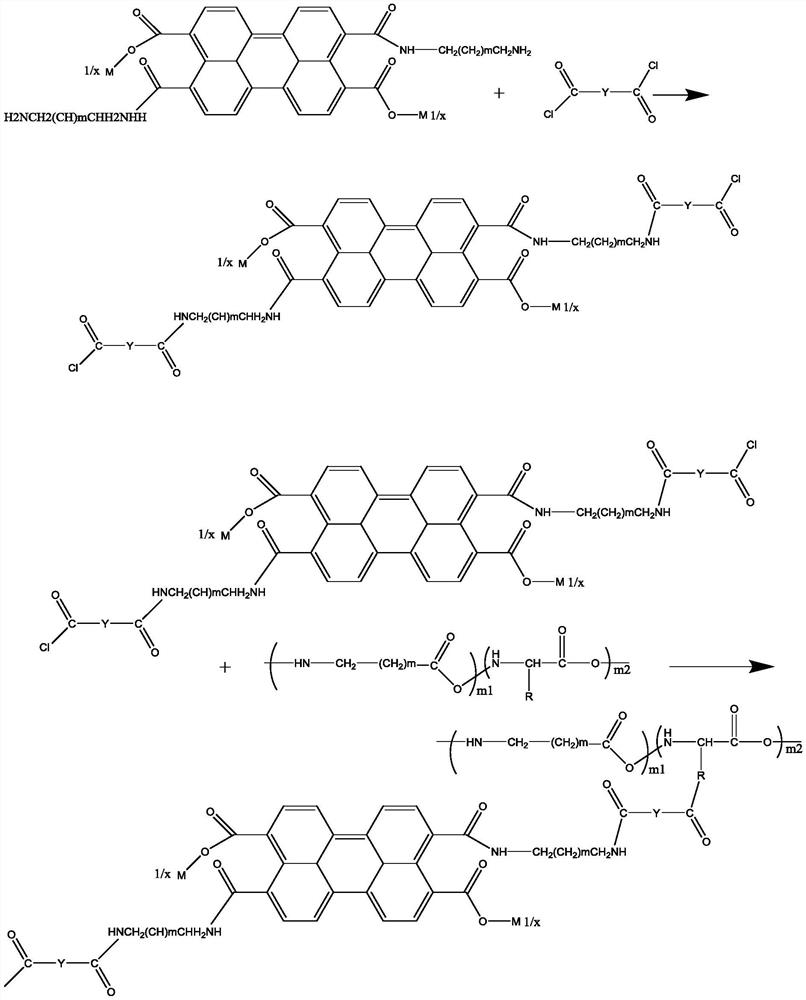

[0043] (2) Synthesizing a polyamino acid (III) with an amino end group as a main chain polyamin...

Embodiment 1

[0055] In a 3L three-necked flask with dry nitrogen protection, stirring and a thermometer, add 392.32g of 3,4,9,10-perylenetetracarboxylic dianhydride dried in vacuum at 80°C, and 1L of calcined calcium oxide dried N,N-dimethylacetamide (DMAc), stirred under the protection of dry nitrogen, added 116.2g of dried 1,6-hexamethylenediamine, and stirred at room temperature for 6 hours. Then add 80g of dried erbium oxide, and continue to stir at normal temperature for 6 hours under the protection of nitrogen. Then pour the reaction solution into normal temperature deionized water, stir and wash, repeat 4 times, and wash 2-3 times with absolute ethanol. Dry in a vacuum oven at 60°C for 10 hours. 650 g of erbium salt (II) of 3,4,9,10-perylenetetracarboxylic acid diamide diacid was obtained.

[0056] Weigh 1050g of ε-aminocaproic acid, 130g of hydroxyproline, and 150g of lysine respectively, add them into a 2500ml three-necked bottle, add 500ml of distilled water, protect with nitro...

Embodiment 2

[0062]In a 3L three-necked flask with dry nitrogen protection, stirring and a thermometer, add 392.32g of 3,4,9,10-perylenetetracarboxylic dianhydride dried in vacuum at 80°C, and 1L of calcined calcium oxide dried N,N-dimethylacetamide (DMAc), stirred under the protection of dry nitrogen, added 116.2g of dried 1,6-hexamethylenediamine, and stirred at room temperature for 6 hours. Then add 80g of dried erbium oxide, and continue to stir at normal temperature for 6 hours under the protection of nitrogen. Then pour the reaction solution into normal temperature deionized water, stir and wash, repeat 4 times, and wash 2-3 times with absolute ethanol. Dry in a vacuum oven at 60° C. for 10 hours; obtain 650 g of 3,4,9,10-perylenetetracarboxylic diamide erbium salt (II).

[0063] Weigh 1162g of ζ-aminoheptanoic acid, 130g of hydroxyproline, and 150g of lysine respectively, add them to a 2500ml three-necked bottle, add 500ml of distilled water, protect with nitrogen, stir and heat up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com