A device that realizes well cellar making and hole fertilization at the same time

A technology for well cellars and power devices, applied in fertilization devices, fertilizer distributors, excavation/covering ditches, etc., can solve the problems of large fertilizer loss, high labor intensity, and low efficiency, and achieve low cost and reduced labor intensity , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

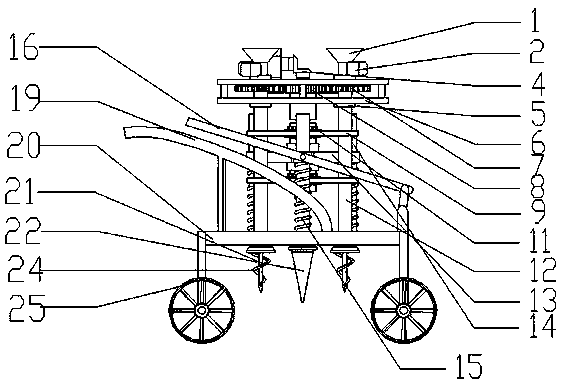

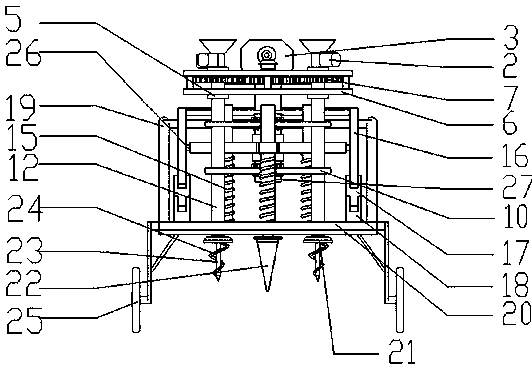

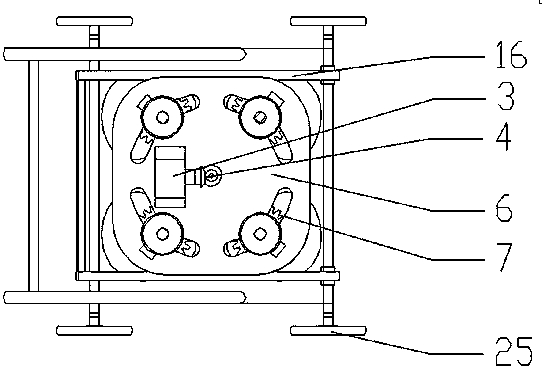

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing, but not as any restriction to the present invention

[0020] Embodiment of the present invention: the device that simultaneously realizes well cellar making and hole fertilization, comprises base 20, is provided with wheel 25 at the bottom of base 20, is provided with fixed plate 6 above base 20, and fixed plate 6 is connected on the ground by lifting mechanism On the base 20; a power unit 3 and a speed change mechanism 4 are arranged on the fixed plate 6, and four feed hoppers 1 are arranged on the top of the fixed plate 6; corresponding to each feed hopper 1, a vertical fertilizer guide pipe is provided 12. The top of the fertilizer guide pipe 12 is connected to the inner ring of the bearing 5 installed on the fixed plate 6, the bottom end of the feed hopper 1 is connected to the outer ring of the bearing 5, the bottom end of the fertilizer guide pipe 12 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com