Interbody fusion cage and method for preparing same

An intervertebral cage and lactic acid technology, which is applied in the field of medical material manufacturing, can solve the problems of local inflammatory reaction, will not be degraded and absorbed by the human body, and the strength is not good enough to prevent thermal degradation and segregation, good osteoinductive activity, good The effect of interface combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] L-PLGA (the molar ratio of LA / GA is 1:1) polymer molecular weight is 350,000, dissolved in dichloromethane, the concentration is 10g / 100ml; Hydroxyapatite (HA) and tricalcium phosphate ( β -TCP) was added to the above solution, the concentration of HA was 3.3g / 100ml, β -The concentration of TCP is 1.1g / 100ml, ultrasonically dispersed for 25 minutes to obtain the reagent (1).

[0025] Dissolve poly-DL-lactic acid (molecular weight: 150,000) in dichloromethane at a concentration of 7.8g / 100ml, mix it with reagent (1), disperse evenly by ultrasonication, then use excess ethanol to obtain a precipitate, and dry it in vacuum to obtain White powder.

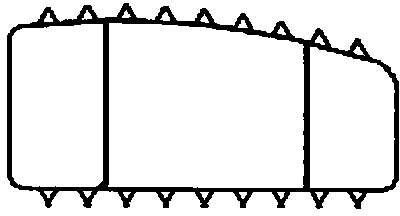

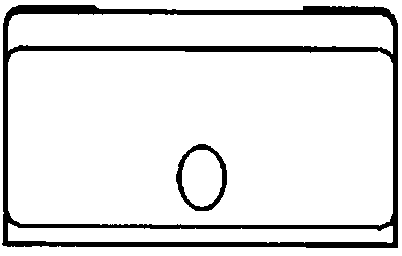

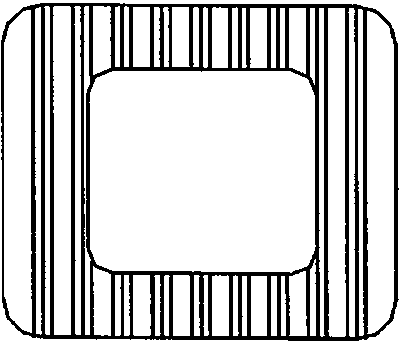

[0026] The intervertebral fusion cage was made by molding with an injection machine at an injection temperature of 200°C. The intervertebral cage is a hollow cylinder with a quadrangular or hexagonal cross section and holes in the side walls. The measured compressive strength of the intervertebral fusion device is 11150N, and...

Embodiment 2-5

[0028] Method is with embodiment 1, and concrete parameter sees the following table:

[0029] The viscosity average molecular weight of the poly-DL-lactic acid (PDLLA) is 100,000 to 300,000, and the viscosity average molecular weight of the L-PLGA is 250,000 to 350,000; in the L-PLGA, L-lactic acid (LA) and ethanol The molar ratio of acid (GA) is 1:1 to 3:1, preferably 2:1. The hydroxyapatite (HA) is selected from surface-modified hydroxyapatite or surface-unmodified hydroxyapatite, and the tricalcium phosphate ( β -TCP) is selected from surface-modified or surface-unmodified tricalcium phosphate.

[0030]

Embodiment 6

[0032] In order to show the irreplaceability of each component of the present invention, the performance indicators of the intervertebral fusion device prepared in Design Comparative Examples 1-4 and Example 2 were compared. Comparative example 1-4 is all with embodiment 2 except concrete composition, and comparative example 1-4 concrete composition is as follows:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com