Method for improving density of foam titanium

A foamed titanium and dense technology, applied in the field of foamed titanium materials, can solve the problems of increasing the difficulty of melt foaming, reducing ductility, and high melting point of titanium, improving microstructure and mechanical properties, increasing adaptability, and improving density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0021] (1) A method for increasing the density of foamed titanium. In the process of preparing foamed titanium by traditional powder metallurgy mixed element method, adding rare earth Er 2 o 3 powder, rare earth Er 2 o 3 The amount of addition is 0.25 wt% to 0.75 wt%. Specific examples are as follows:

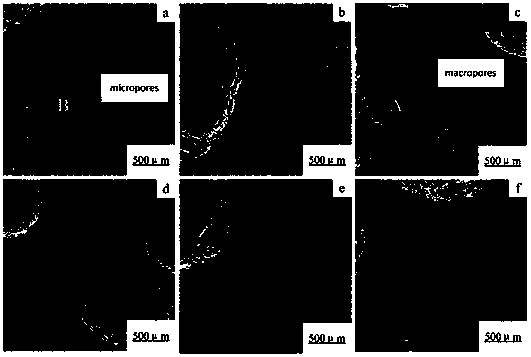

[0022] With HDH titanium powder (purity ≥ 99%, particle size ≤ 50μm) and rare earth Er 2 o 3 Powder (purity≥99.95%, particle size≤10μm) is used as raw material, urea particles (particle size between 700-1000μm) are used as pore-forming agent, and titanium foam is prepared by traditional powder metallurgy mixed element method. The experiment is designed according to the porosity of 70%, the sample size is φ12mm×10 mm, the rare earth Er 2 o 3 The amount of powder added is set to 6 levels: 0, 0.25, 0.50, 0.75, 1.0, 2.0wt%, as shown in Table 1.

[0023] Table 1 Er2O3 content corresponding to different samples

[0024]

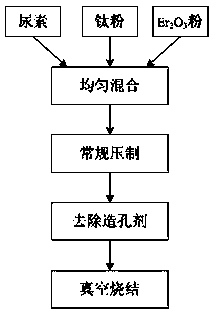

[0025] Such as figure 1 As shown, the main proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com