Composite fiber, manufacturing method and orthopedic binding wire

A composite fiber and bundling wire technology, applied in the field of medical devices, achieves the effects of good elasticity, easy knotting and increased friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] 1. Preparation of composite fibers

[0023] The composite fiber of the invention is made by compounding polyamide 6 fiber and poly(methyl methacrylate-co-N-vinylpyrrolidone) polymer. Polyamide 6 fibers can be commercially available, with a number-average molecular weight of 15,000-30,000; poly(methyl methacrylate-co-N-vinylpyrrolidone) polymers can be obtained by polymerization, with a number-average molecular weight of 7-20 Ten thousand.

[0024] The preparation method comprises two steps of surface activation of the polyamide 6 fiber and coating and compounding. Surface activation can be performed using an acid solution, for example, surface-activated polyamide 6 fibers can be obtained by soaking polyamide 6 fibers in an acid solution. Afterwards, the surface-activated polyamide 6 fiber is immersed in the viscous liquid of poly(methyl methacrylate-co-N-vinylpyrrolidone) polymer, so that the latter is coated and composited on the surface of the polyamide 6 fiber . ...

specific Embodiment

[0031] In the examples, the characterization of the tensile strength and water absorption of the fibers is carried out by means commonly used in the field, so details are not repeated here.

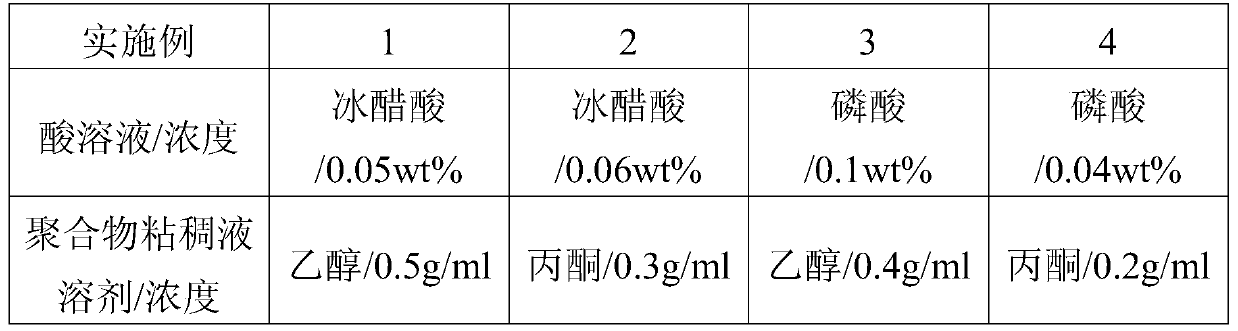

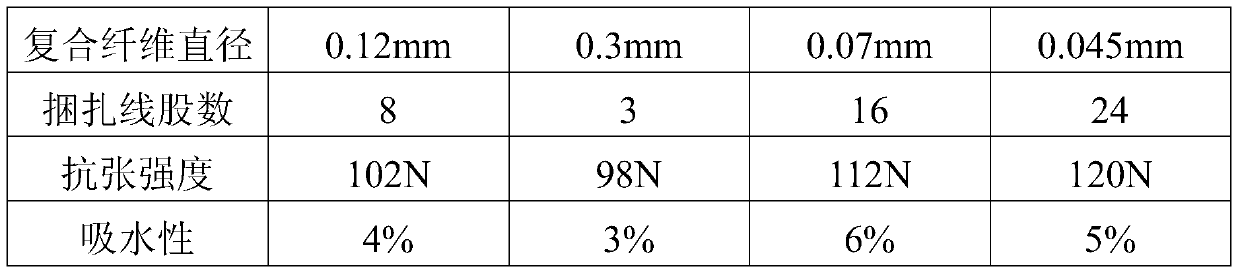

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com