Vehicle transmission control mechanism assembly testing bench

A technology for automobile gearboxes and operating mechanisms, applied in the field of test benches, which can solve problems such as complex system maintenance, damping force test and control program errors, and troublesome program modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

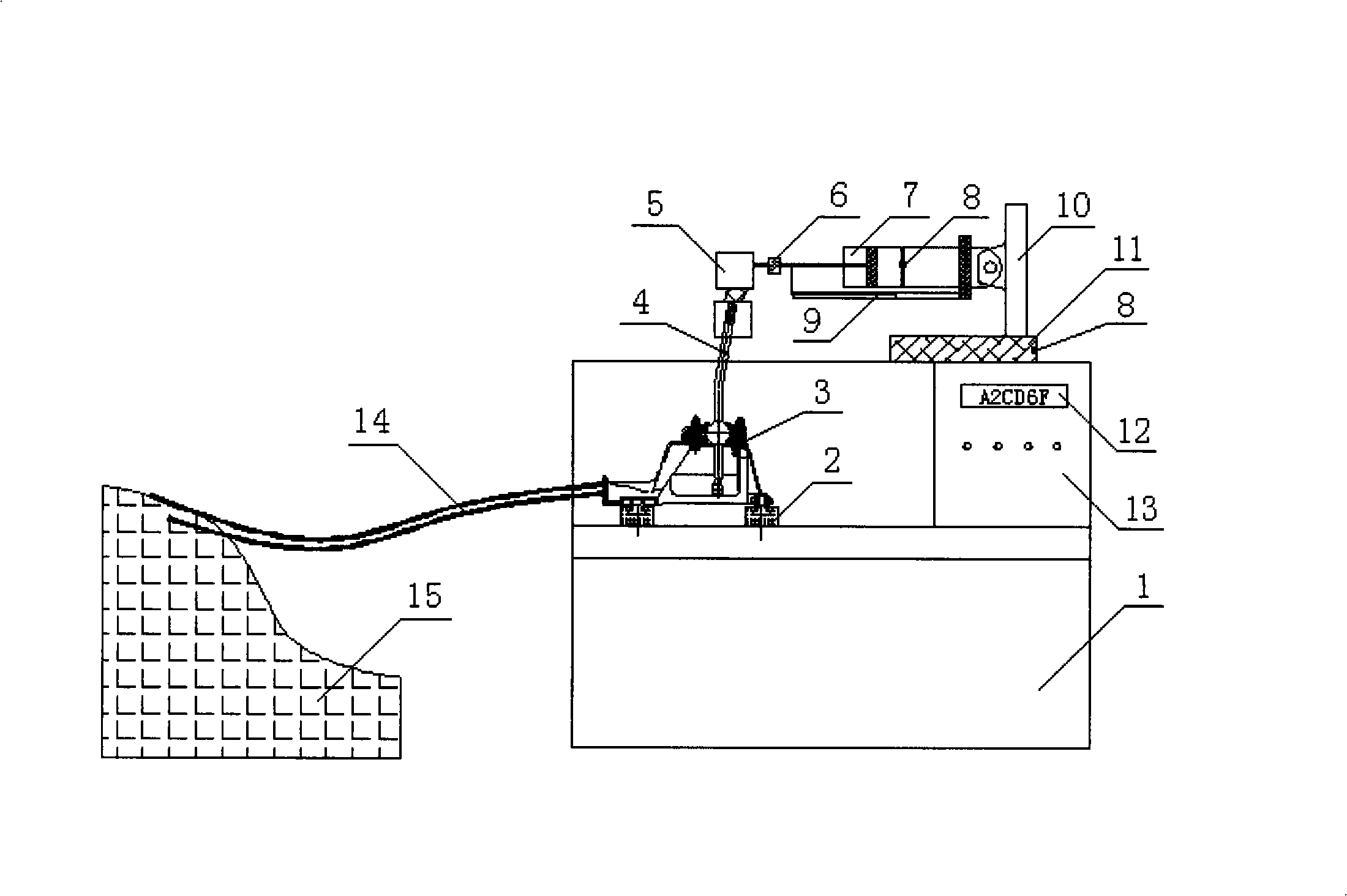

[0016] figure 1 Shown is a schematic diagram of the structure of the test bench for the control mechanism assembly of the automobile transmission. The test bench for the control mechanism assembly of the automobile transmission includes a test bench body 1, which is located in the test bench body 1, and the front end is fixedly installed with a six-direction movable The adjusted installation and adjustment frame 2, the automobile transmission and shifting control mechanism assembly 3 is installed on the installation and adjustment frame 2, the output end of the automobile transmission and shifting operation mechanism assembly 3 is connected with the gearbox 15 through the selection and shifting cable 14, and is located at A PLC control system control frame 13 is installed on the rear side wall of the test bench body 1 , and a cylinder loading system and a load system are arranged above the test bench body 1 .

[0017] The structure of the cylinder loading system is: the gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com