Electrical variable-speed case and its dynamic mode

A continuously variable transmission, electric power technology, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of inconvenient manufacturing and process, difficult to realize, high absolute speed of internal motor, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

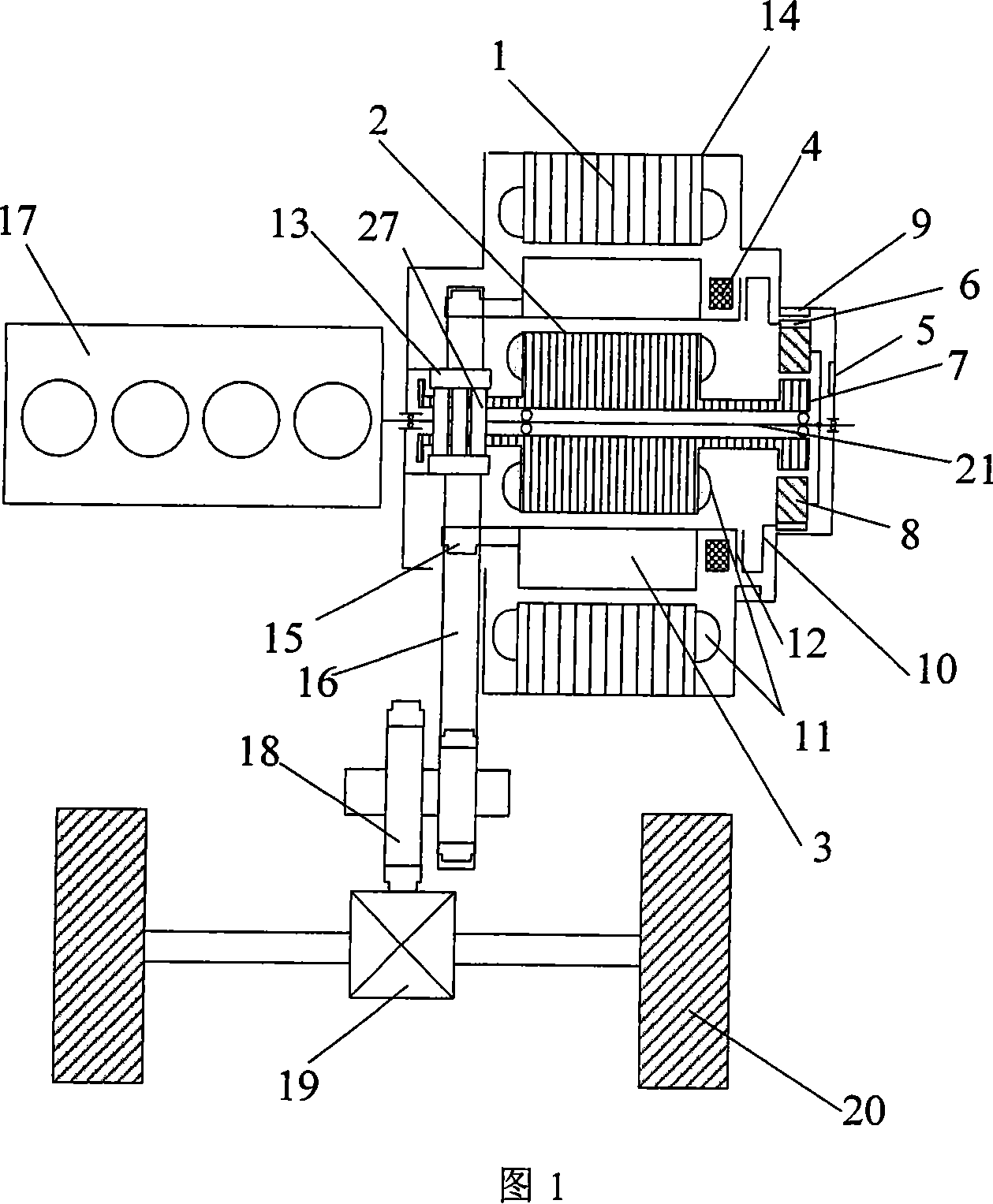

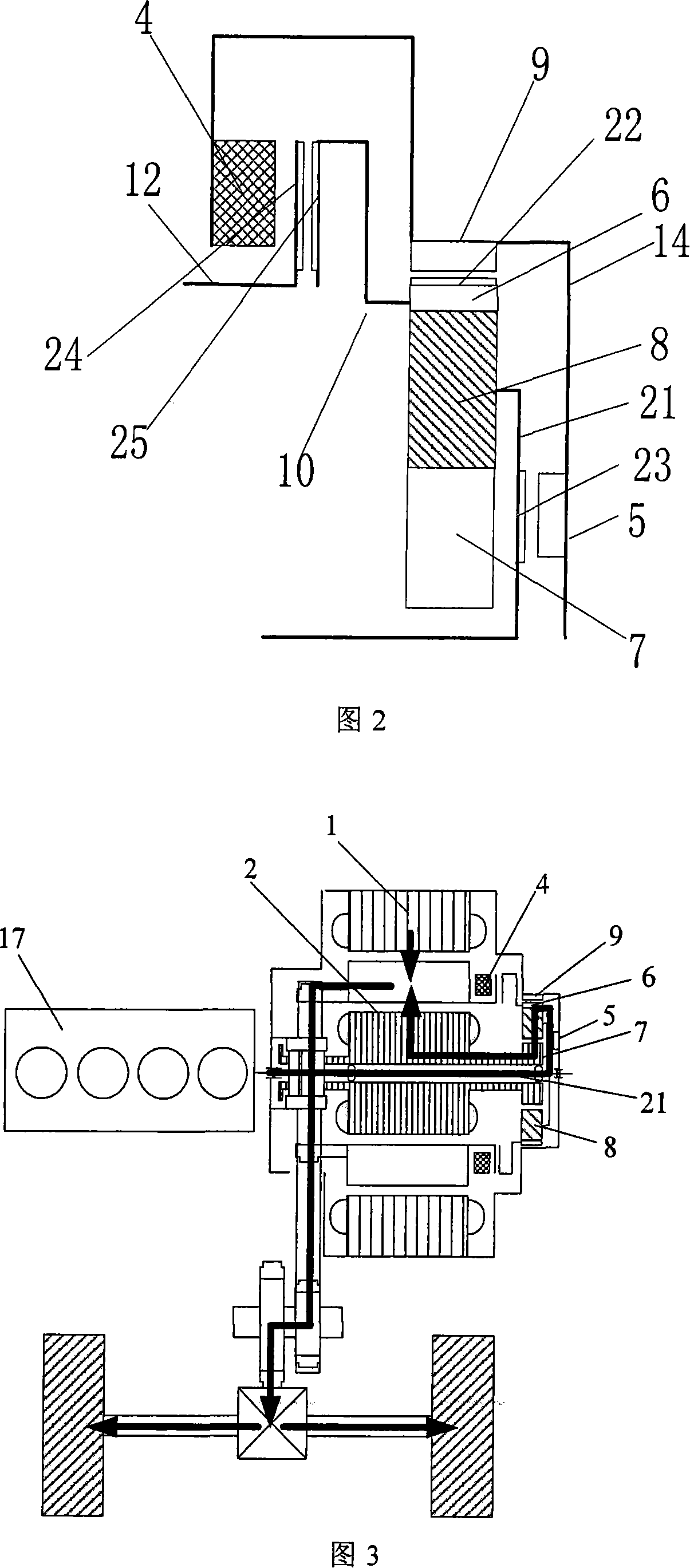

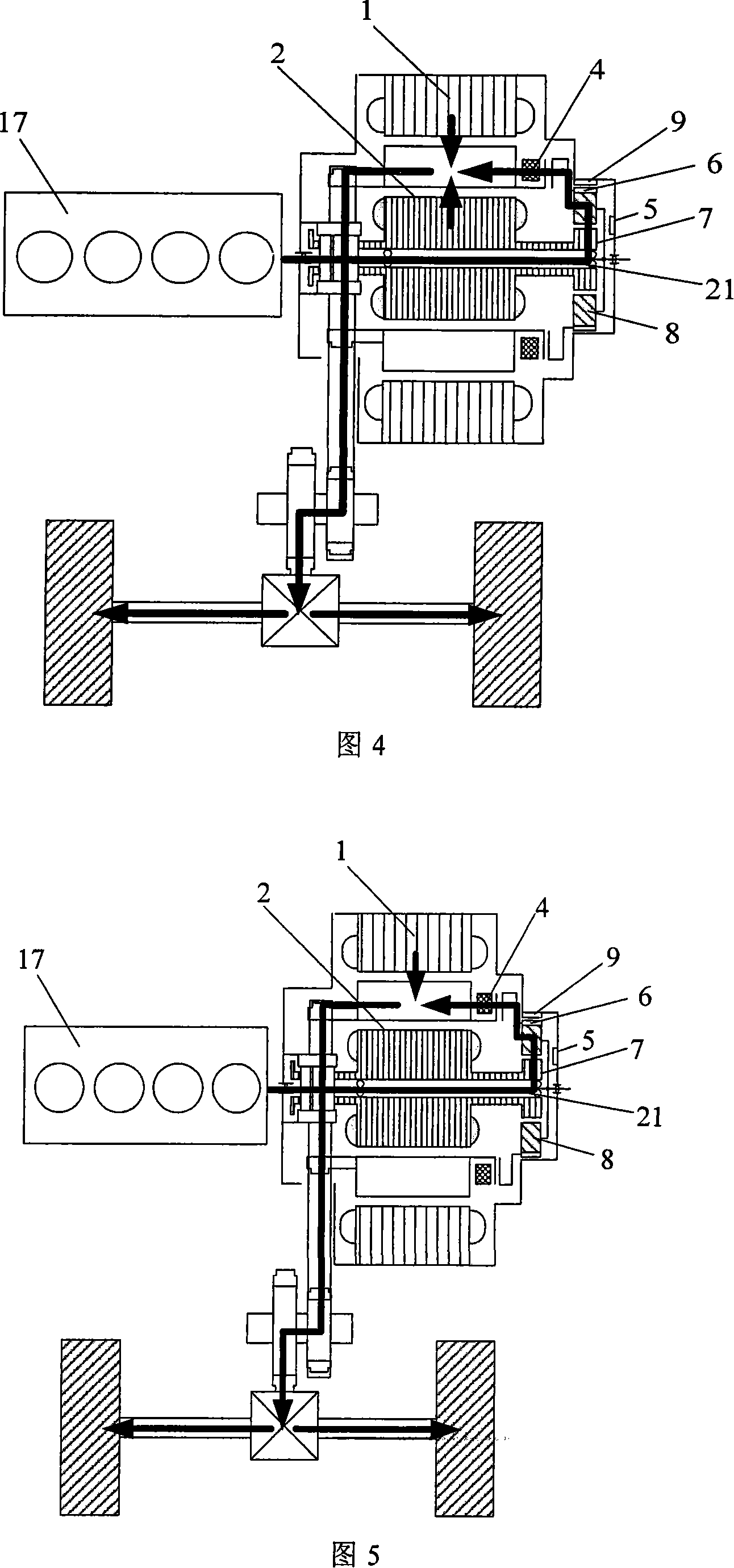

[0028]Fig. 1 is a schematic diagram of the electric continuously variable transmission of the present invention and its connection mode of Solution 1 on the mounting platform. The electric continuously variable transmission of the present invention mainly includes two parts of a double mechanical port motor and a planetary gear. As shown in Figure 1, the dual mechanical port motor is a three-layer structure arranged concentrically, the outermost layer is the stator 1, the middle is the outer rotor 3, and the innermost layer is the inner rotor 2. Wherein, armature windings 11 are installed on the stator 1 and the inner rotor 2 . The inner rotor current passes through the brushes 13 and slip rings 27 from the external power supply to the armature winding of the inner rotor 2 . Planetary gear is made up of planet carrier 8, sun gear 7 and ring g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com