Isothermal graded quenching oil composition and uses thereof

A grading quenching oil, isothermal technology, applied in the direction of quenching agent, lubricating composition, petroleum industry, etc., can solve the problem of not having the anti-corrosion performance of the workpiece, and achieve the effects of small deformation, easy cleaning and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

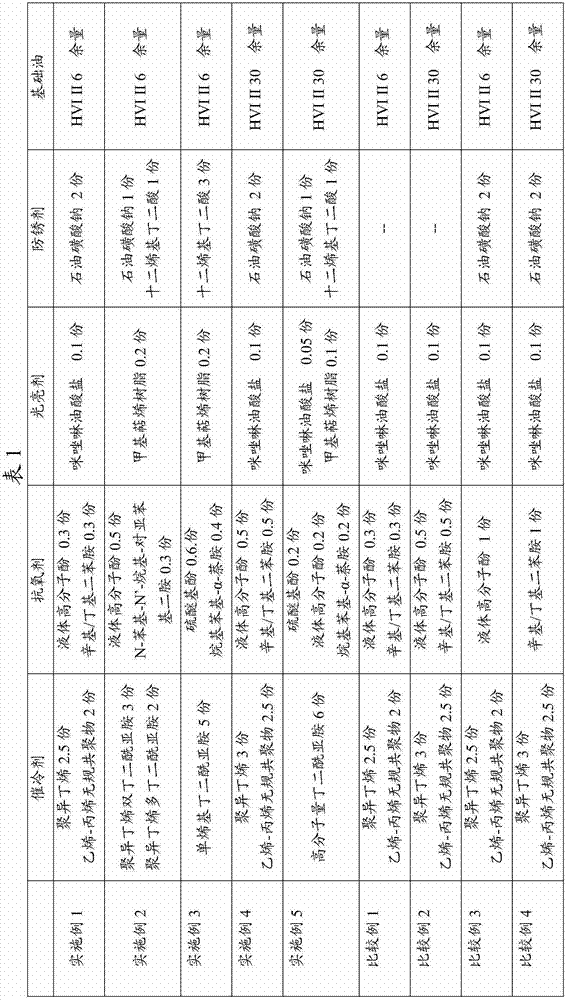

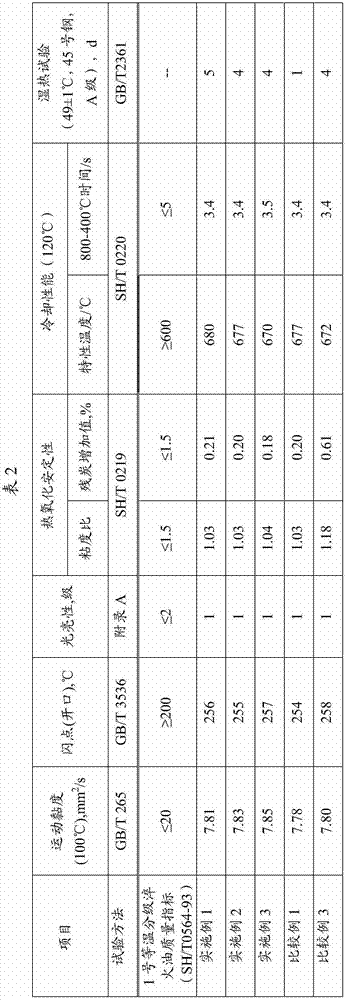

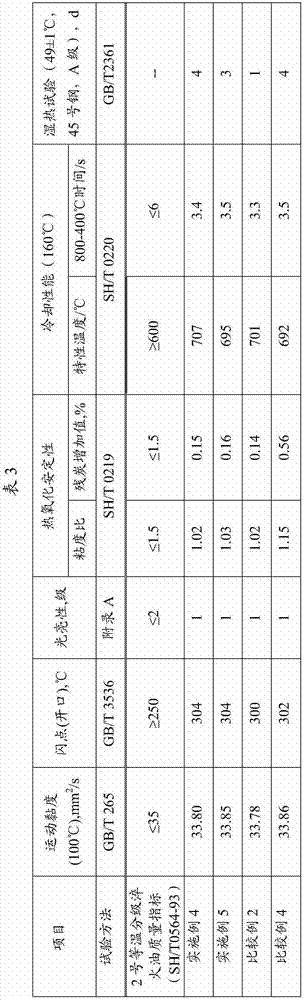

[0031] Pump the base oil into the blending kettle, turn on the agitator and the heating switch, and when the oil is heated to 65°C, add the required amount of each component in turn, and continue to heat and stir at 65°C for 3 hours to obtain a uniform yellow liquid. The components and contents of the isothermal graded quenching oil composition are shown in Table 1, and the corresponding performance index results are shown in Tables 2 and 3.

[0032] in,

[0033] Liquid Polymer Phenol, Produced by Shanghai Yucheng Chemical Co., Ltd.

[0034] Octyl / Butyldiphenylamine, Produced by Shanghai Yucheng Chemical Co., Ltd.

[0035] HVI II6, lubricating base oil, produced by Jingmen Oil Refinery, kinematic viscosity at 100°C is 6.12mm 2 ·s -1 .

[0036] HVI II30, lubricating base oil, produced by Jingmen Oil Refinery, kinematic viscosity at 100°C is 29.16mm 2 ·s -1 .

[0037]

Embodiment 10

[0047] The isothermal graded quenching oil composition of [Examples 1-5] was used in the high-temperature quenching process, and the cooling curve of the oil product is shown in Fig. 1 and Fig. 2 .

[0048]During the use of the oil, it exhibits excellent cooling performance, thermal oxidation stability and brightness. After quenching, the workpiece has high hardness, small deformation, bright surface, less sludge at high temperature, and long service life. After quenching, it has a certain effect on the workpiece. Excellent short-term anti-rust effect, easy to clean later, saves the step of applying anti-rust oil, and saves production costs.

Embodiment 4

[0049] [Example 4] The isothermal graded quenching oil of the present invention is used at 160°C to quench the parts and components of an automobile gearbox in a certain factory in Hubei Province. Table 4.

[0050]

[0051]

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com