55KW grade electricity loading test stand for automobile gear box low noise energy-conserving type under line detection and working method thereof

A technology of automobile gearbox and test bench, which is applied in the direction of vehicle testing, sustainable manufacturing/processing, testing of machine/structural components, etc. It can solve the problems of low degree of automation, incapable of multi-variety experiments, small torque, etc., and achieve saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

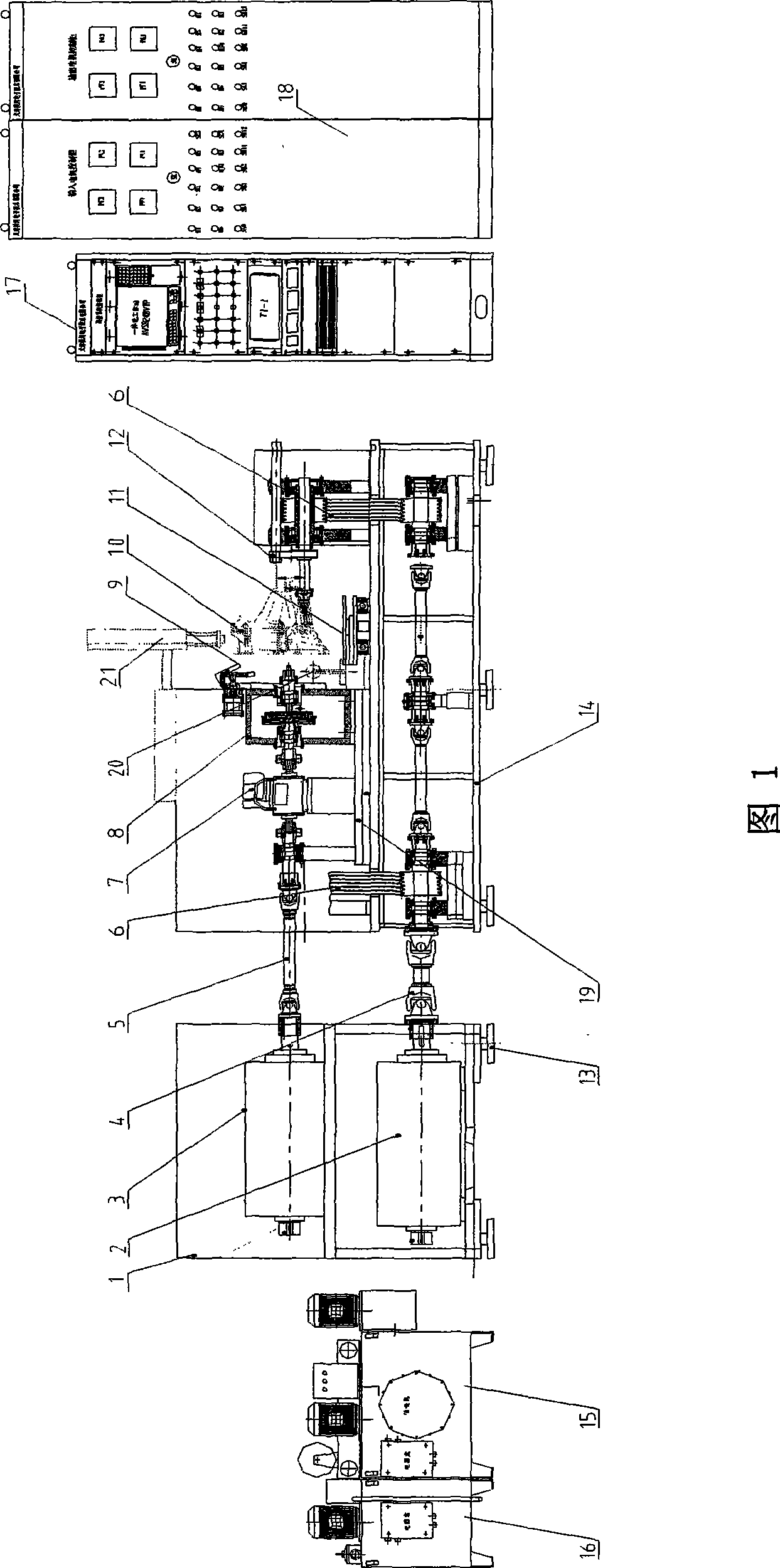

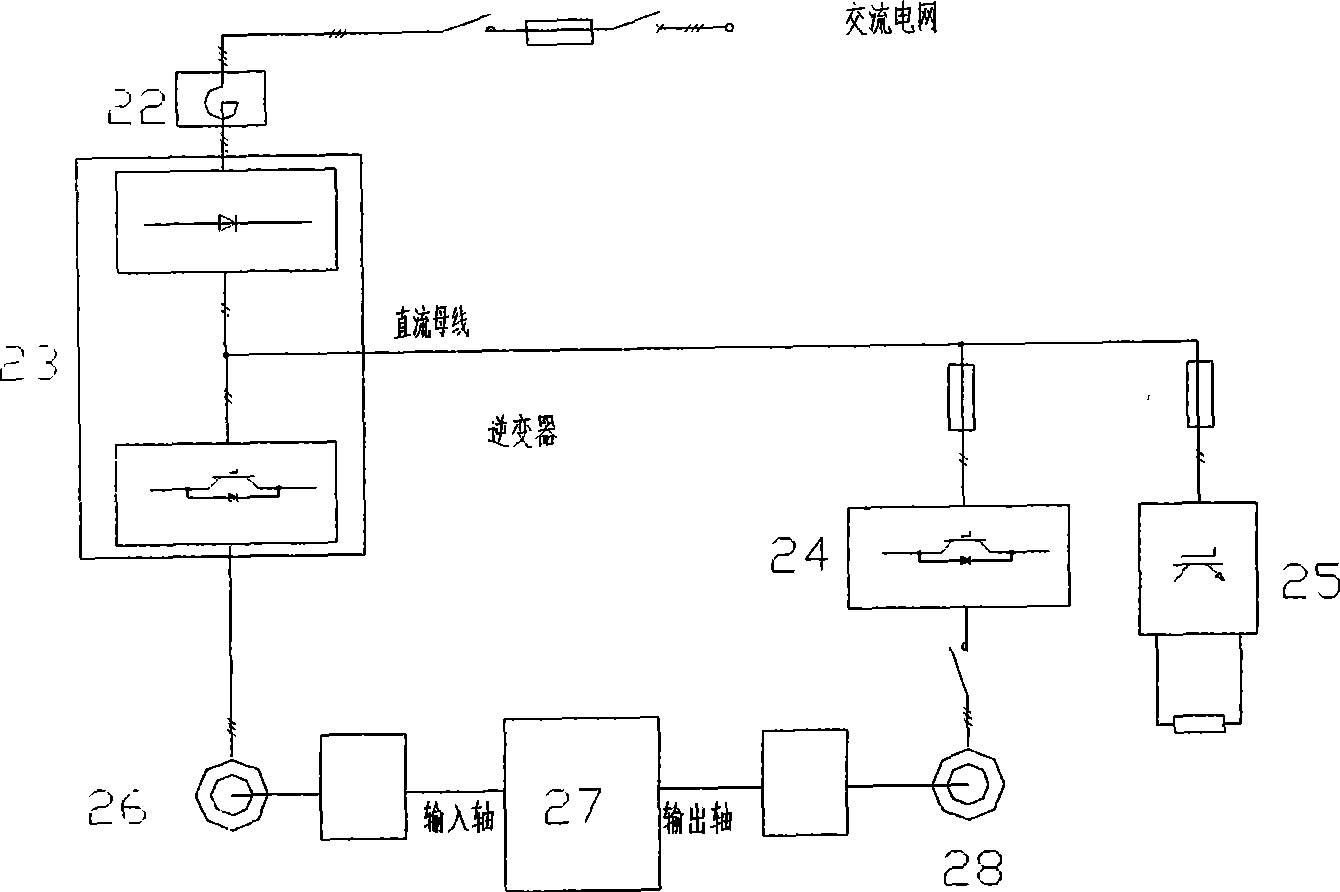

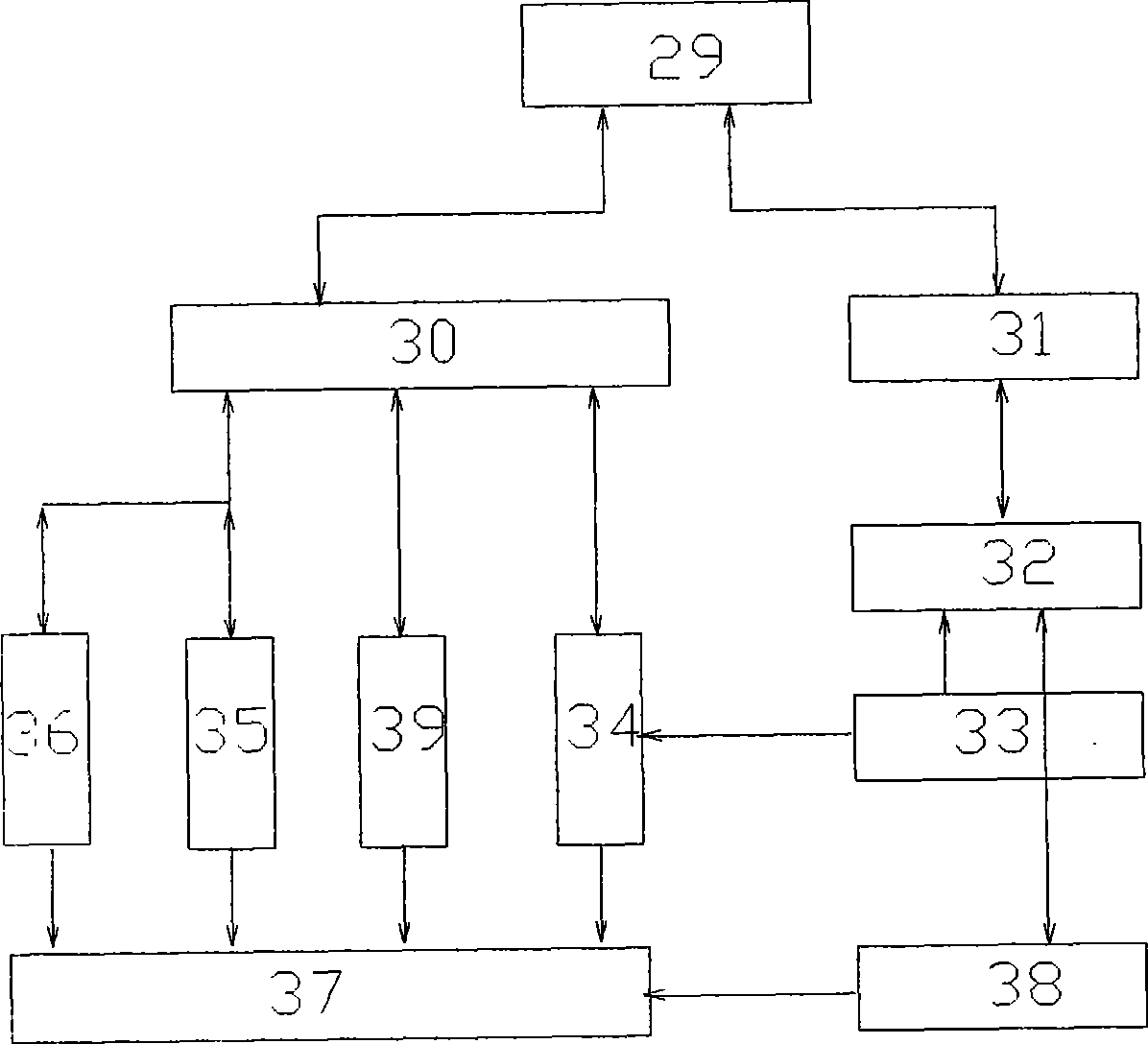

[0032] Embodiment: A kind of low-noise and energy-saving type off-line detection 55KW electric load test bench for automobile gearbox, including test bench main body and motor box (see Figure 1), electric transmission control system (see figure 2 ), computer measurement and control system (see image 3 ), centralized oil supply hydraulic station (see Figure 1); it is characterized in that a handle shift force operation measurement device and a noise measurement device are installed on the test bench, and the shift mechanism of the tested gearbox is connected to the handle shift force operation Measuring device, the test probe of the noise measuring device is automatically placed at 50 mm above the input axis of the tested gearbox; the main body of the test bench and the motor box include the input shaft drive loading motor 3, the input shaft torque speed sensor 7, the clutch unit 8. Transmission installation transition plate, fast positioning and clamping device of the tested ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com