Dynamic balance method of impeller

A dynamic balancing machine and impeller technology, which is applied in the field of dynamic balancing of impellers, can solve problems such as easy generation of aerodynamic noise, excess breeding blocks, gas disturbance, etc., and achieve the effects of reducing aerodynamic noise, improving fan efficiency, and avoiding howling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

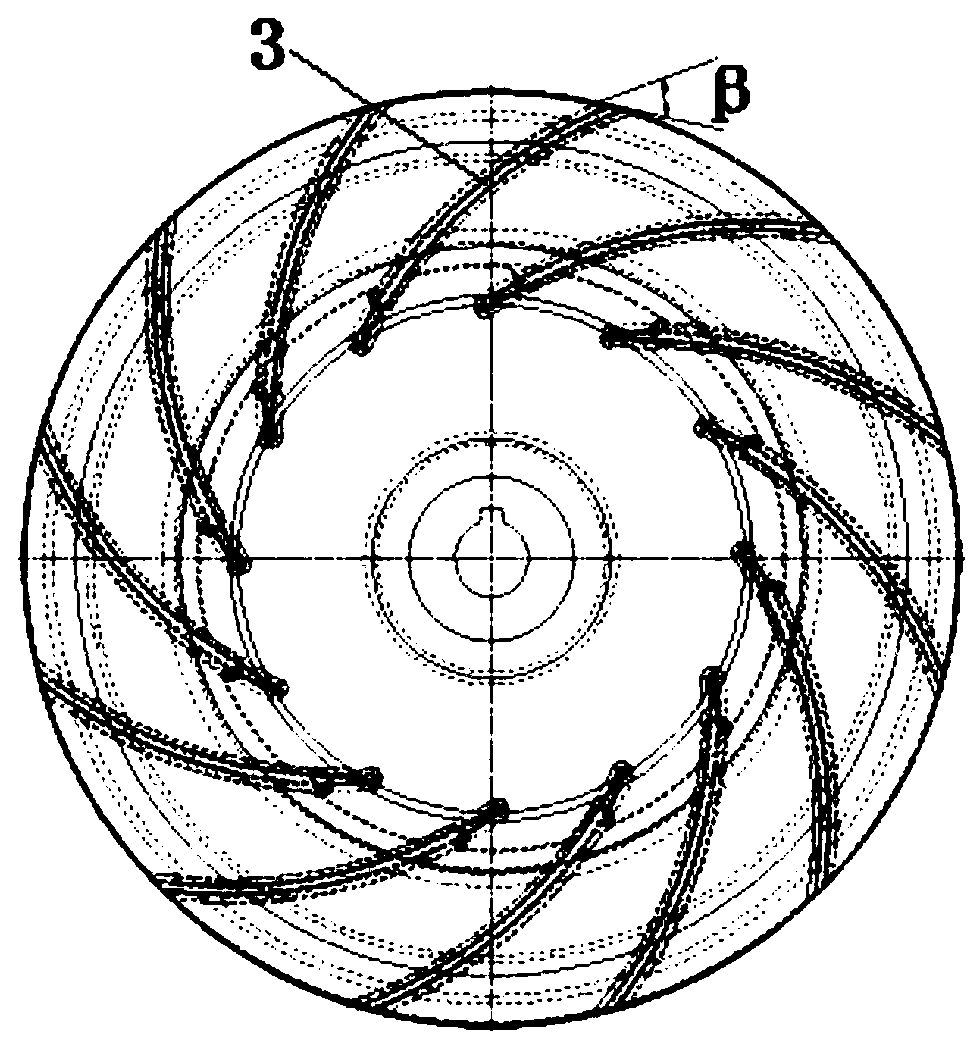

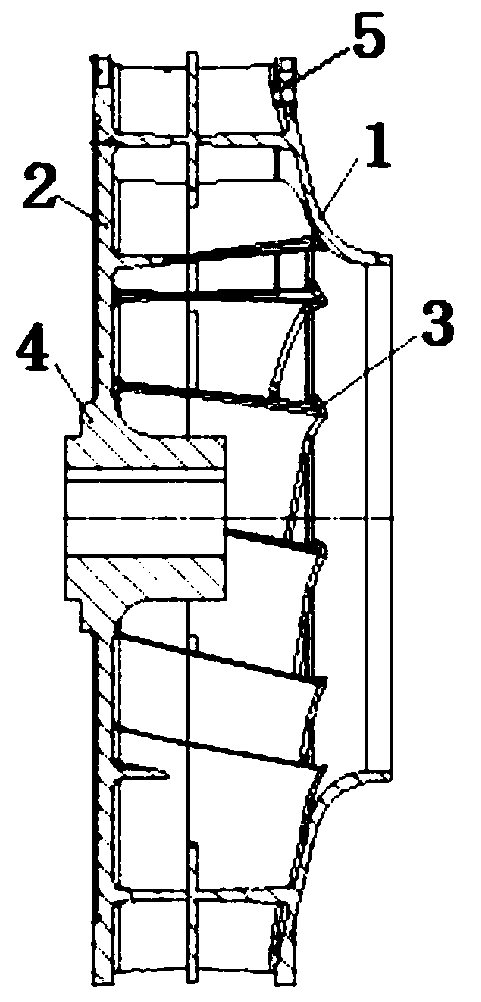

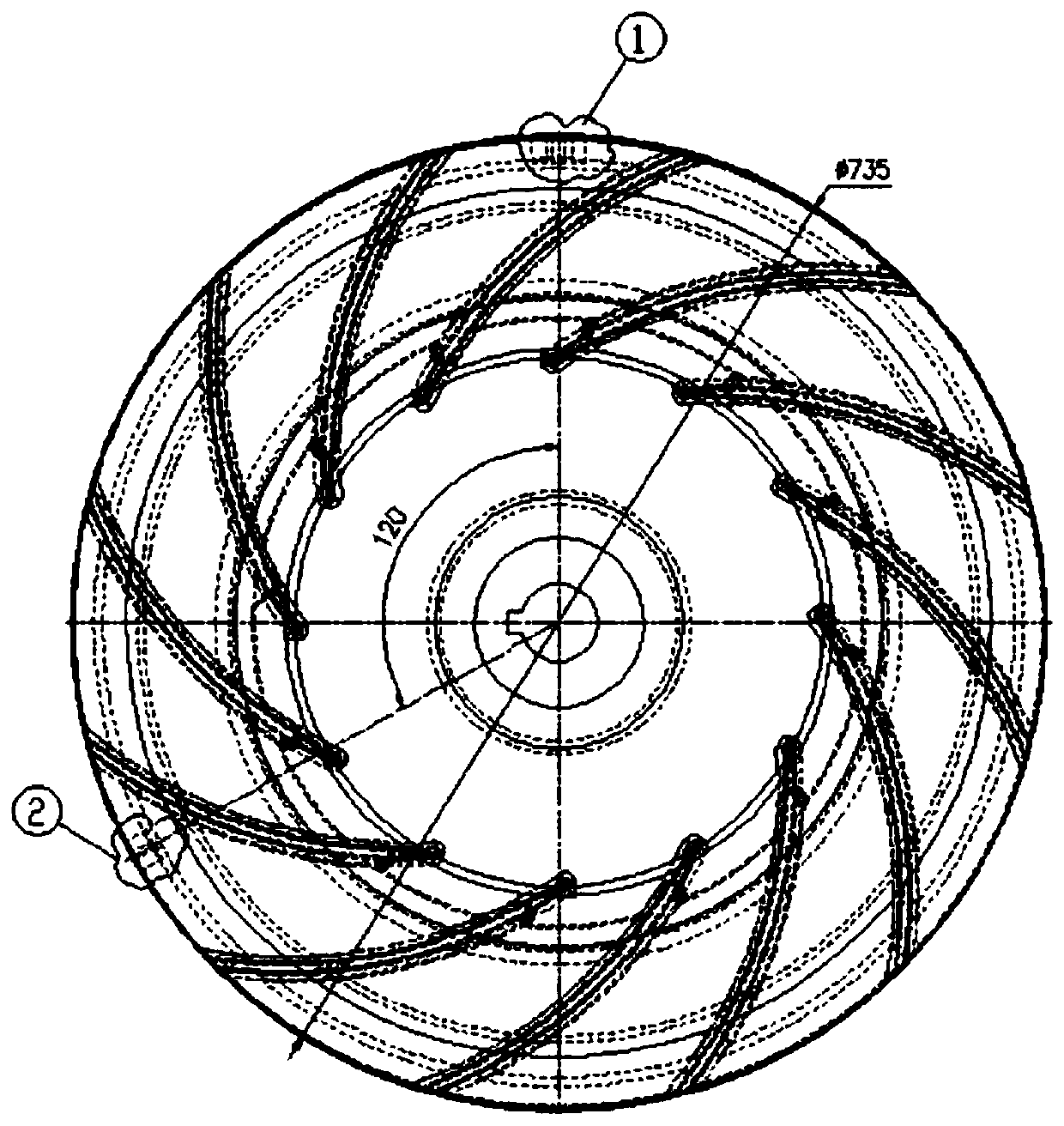

[0031] Such as figure 1 , figure 2 As shown, the impeller includes a wheel cover 1, a wheel disc 2, a blade 3, a shaft disc 4, and a wheel cover 5.

[0032] Wherein, the wheel cover 5, the blade 3, the wheel disc 2, and the wheel cover 1 are all formed into a whole by mold casting.

[0033] Wheel cover 5 can be straight shape, taper, arc.

[0034] The blades 3 can be forward, backward or radial, and NTFB mostly adopts backward blades, such as figure 1 As shown, the blade distribution form in which β<90° is called backward blade.

[0035] The wheel disc 2 and the wheel cover 5 have the same outer diameter, and the outer rings of the wheel disc and the wheel cover are cast with a 3-5mm thick boss edge, which is used for impeller reinforcement and dynamic balancing.

[0036] A method for dynamically balancing a cast aluminum impeller, comprising the following steps:

[0037] Step 1. Use a dynamic balancing machine to perform a dynamic balancing test on the impeller, and det...

Embodiment 2

[0071] In the dynamic balancing method of this embodiment, when the rotating speed of the impeller is lower than 1500r / min, the dynamic balancing method of drilling and tapping the radial edge of the impeller and then injecting lead water can be adopted.

[0072] The scheme of this embodiment can only be used under the condition that the speed of the impeller is lower than 1500r / min. If the speed of the impeller is higher than 1500r / min, the lead weight of the counterweight will be thrown out due to the large centrifugal force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com