Large-flow high-frequency electrohydraulic exciting shock control valve drive system

A drive system, high-frequency electric technology, applied in fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve problems such as limited excitation frequency, overload of hydraulic system, small flow rate, etc., to achieve improved Effect of excitation frequency, avoiding overload, overcoming frictional moment and fluid damping moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

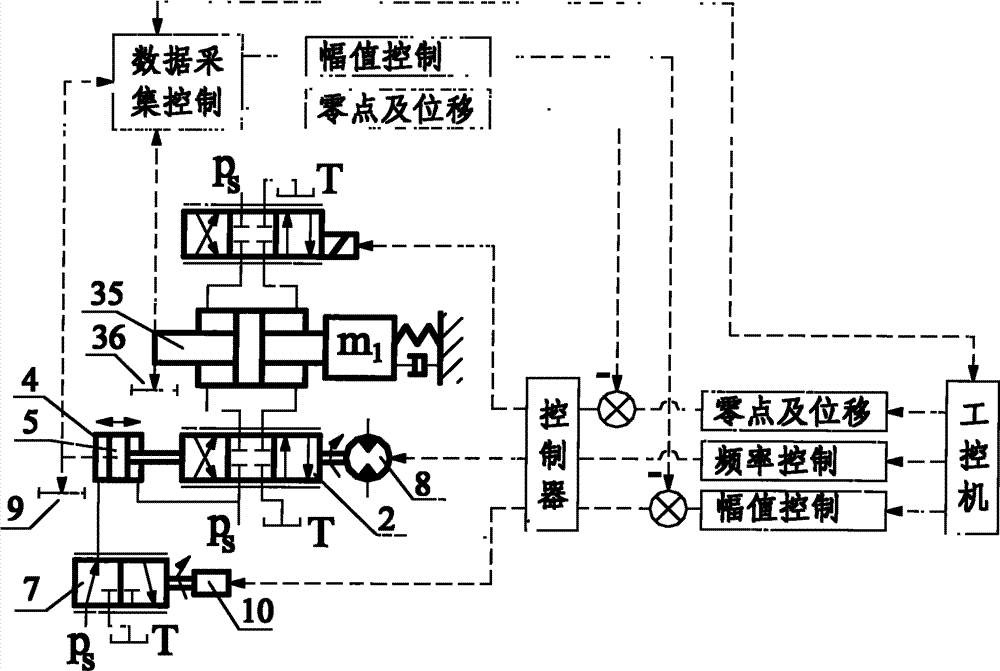

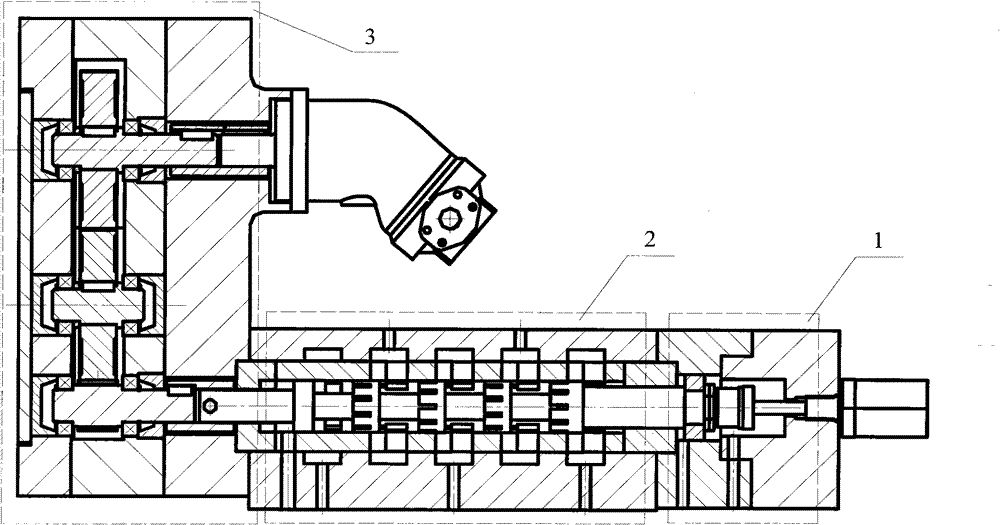

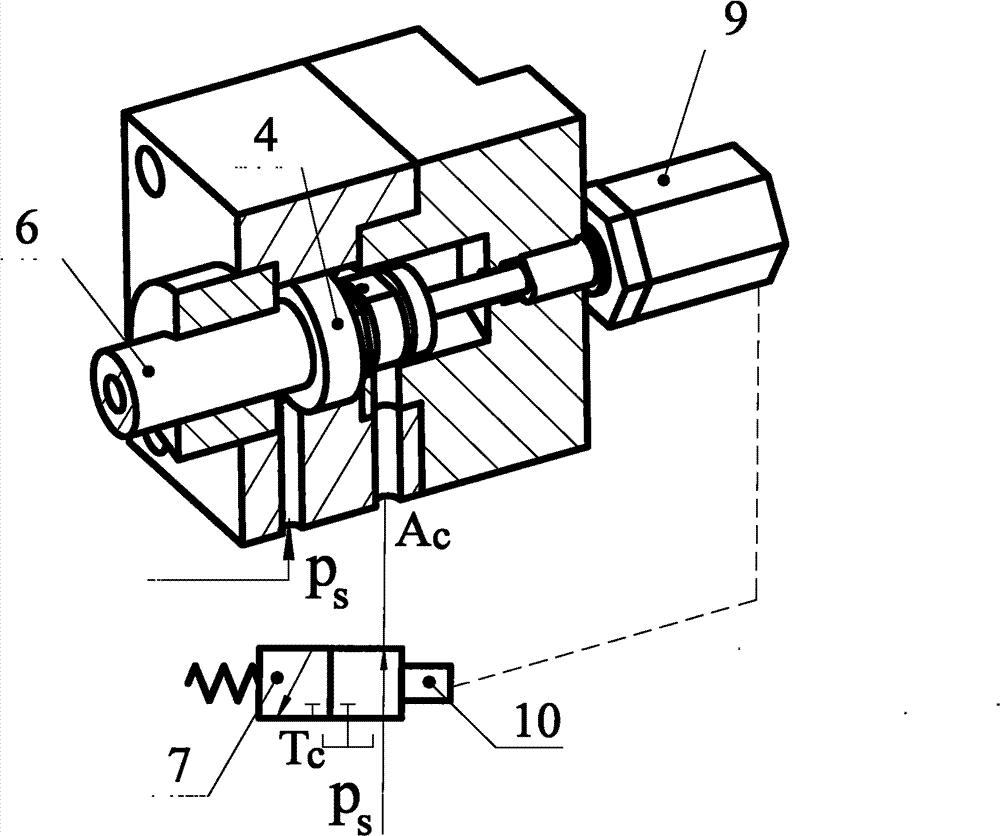

[0025] refer to Figure 1 to Figure 8 , a high-flow high-frequency electro-hydraulic excitation control valve drive system, including a large-flow high-frequency electro-hydraulic excitation valve 2, a hydraulic cylinder 1 at the end of the main valve for driving the valve core to slide axially and linearly, and a hydraulic cylinder for driving the valve The transmission 3 with core rotation, the hydraulic cylinder 1 at the end of the main valve includes a cylinder body 4 and a driving piston 5, the driving piston 5 is fixedly installed at the end of the valve core 6, and the driving piston is used in the cylinder as a The cylinder block on one side of the valve core is a rod chamber, and the cylinder body on the other side is a rodless chamber. The rod chamber communicates with the high-pressure fuel tank, and the rodless chamber communicates with the high-pressure fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com