Tire mold high speed high precision parallel machining constitution method

A tire mold, high-precision technology, used in simulators, program control, instruments, etc., can solve the problems of poor contract performance and long manufacturing cycle, and achieve the effect of reducing manufacturing time, ensuring standardization, and shortening design cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

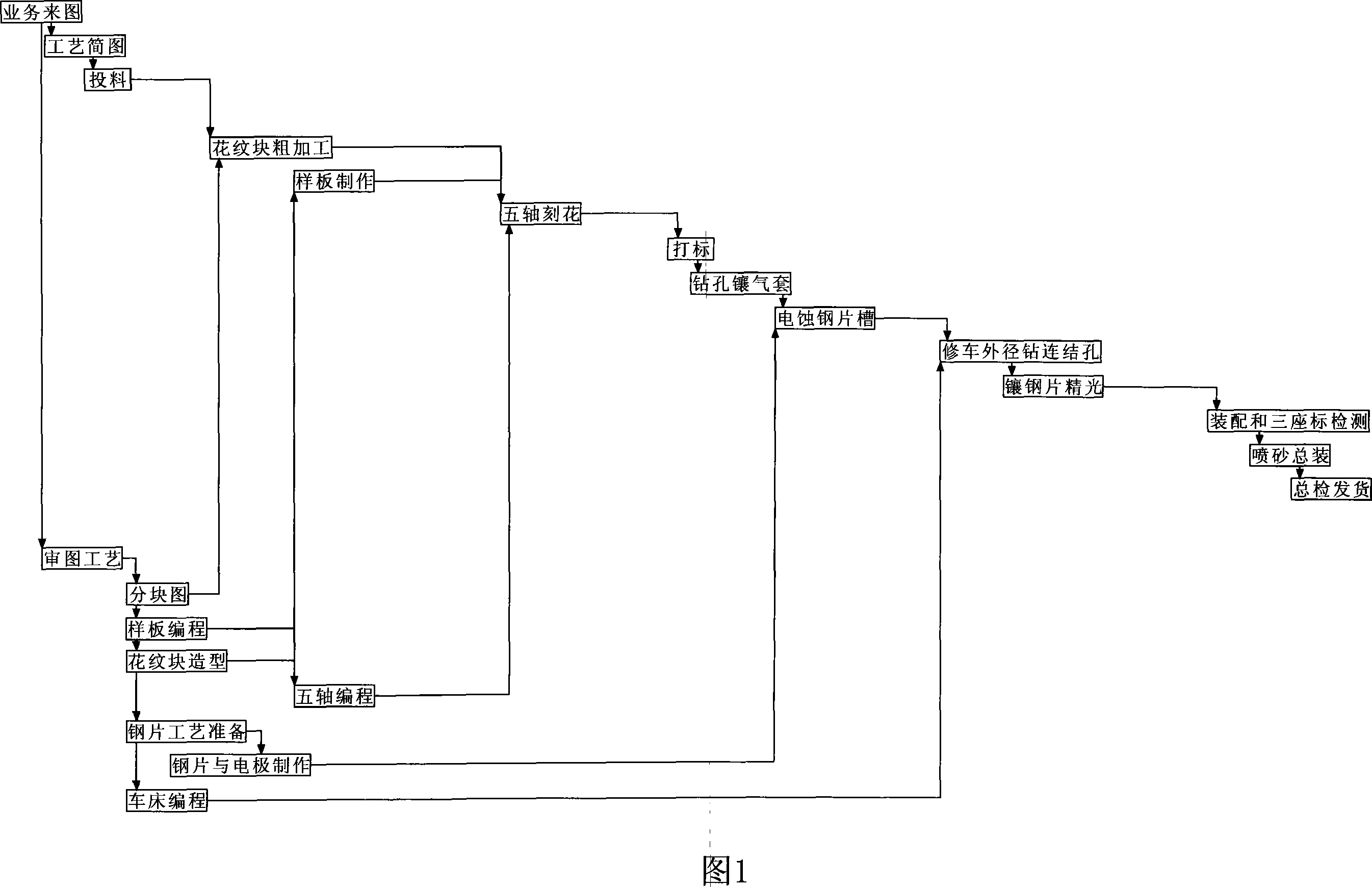

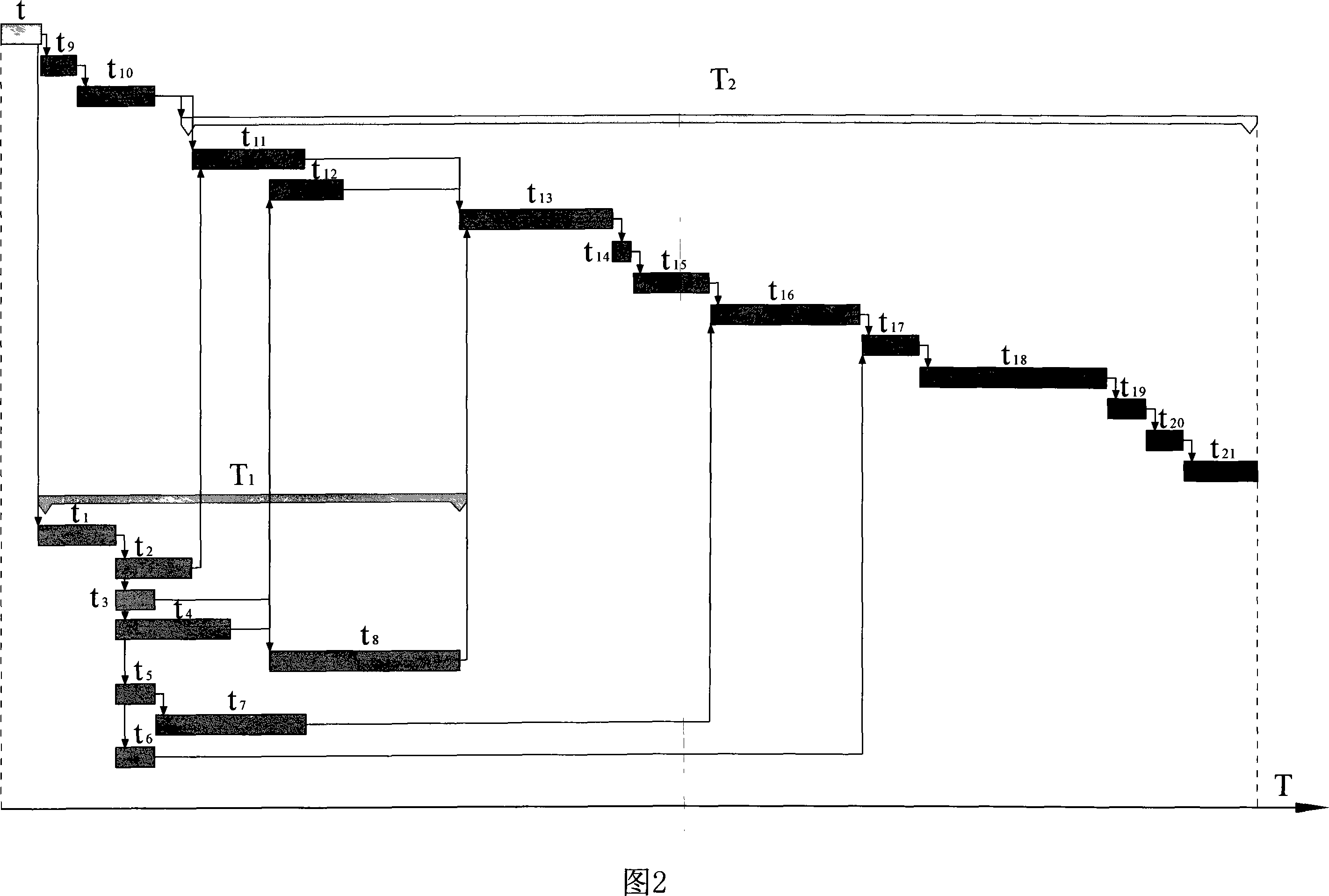

[0049] Example: Parallel processing flow of tire mold high-speed and high-precision pattern blocks

[0050] With reference to Fig. 1, Fig. 2, the present embodiment comprises:

[0051] A. Parallel design and manufacturing process:

[0052] Through the establishment of CAD library, the implementation of modular design shortens the design cycle; the establishment of a typical cross-section process library, the implementation of CAPP, the use of standard process cards, to ensure the reliability and standardization of process design, and shorten the time for process preparation;

[0053] Starting from the mold cavity, compile a typical mold cavity process scheme atlas, including two parts: the first part is a typical mold cavity parts process scheme atlas, which is divided into upper and lower side plates and pattern blocks, and the processing methods for its parts , description of structural characteristics and reasons for scheme selection are stipulated in the form of an atlas;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com