Micro piezoelectric-electromagnetic composite power generation device

An electromagnetic composite and power generation device technology, applied in the field of MEMS and micro energy, can solve the problems of easy pollution of the environment, the need for regular replacement, and the limited energy of chemical batteries, so as to speed up the cutting of magnetic induction lines, improve power generation efficiency, and increase energy. The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

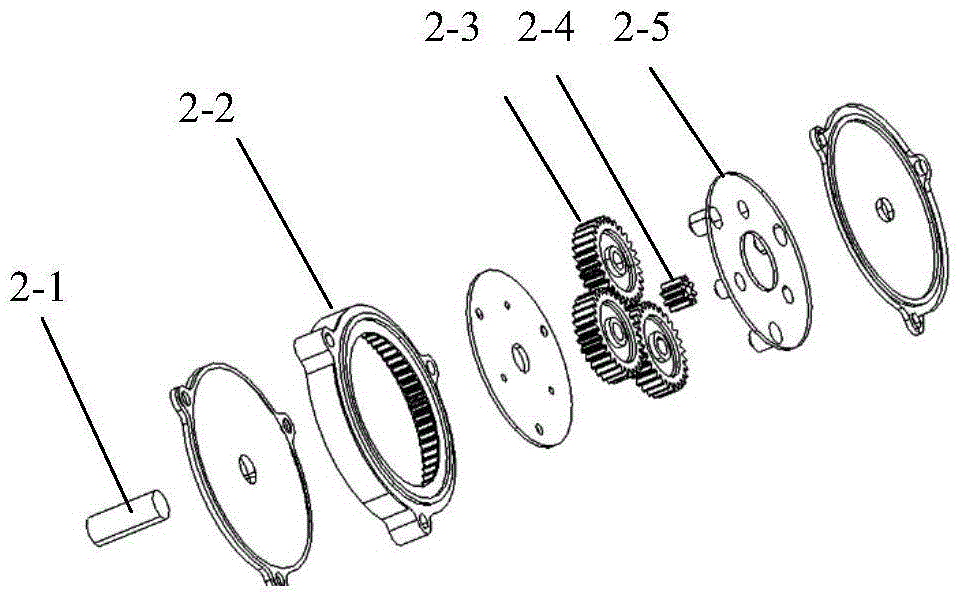

[0025] In the present invention, the number of piezoelectric vibrators and coils is not limited. In this embodiment, six piezoelectric vibrators and coils are alternately distributed as an example.

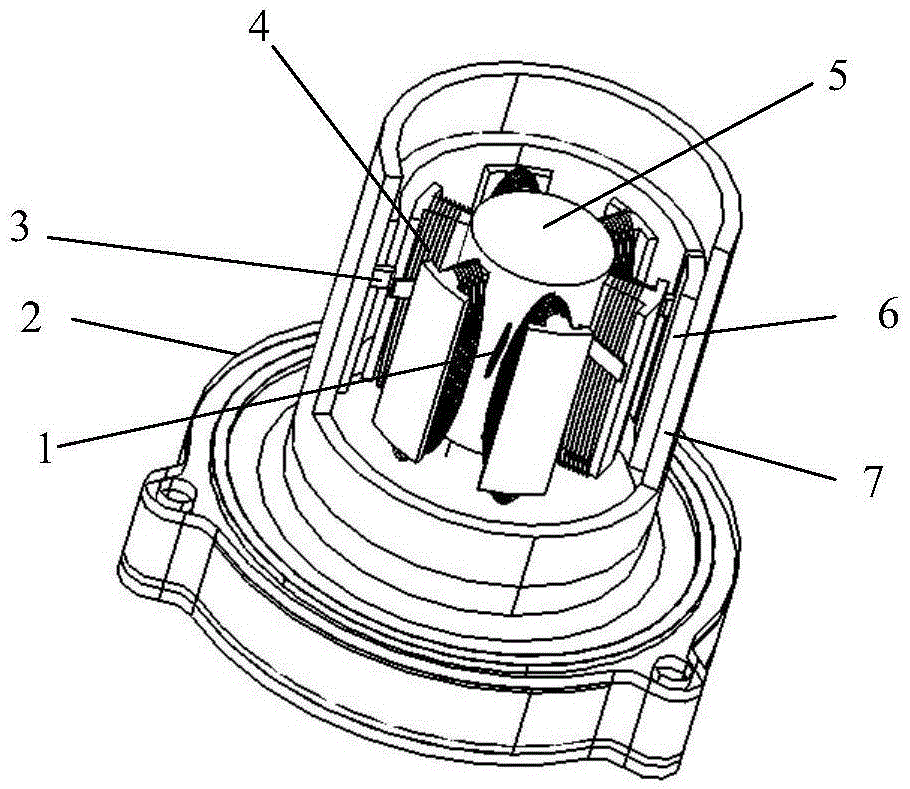

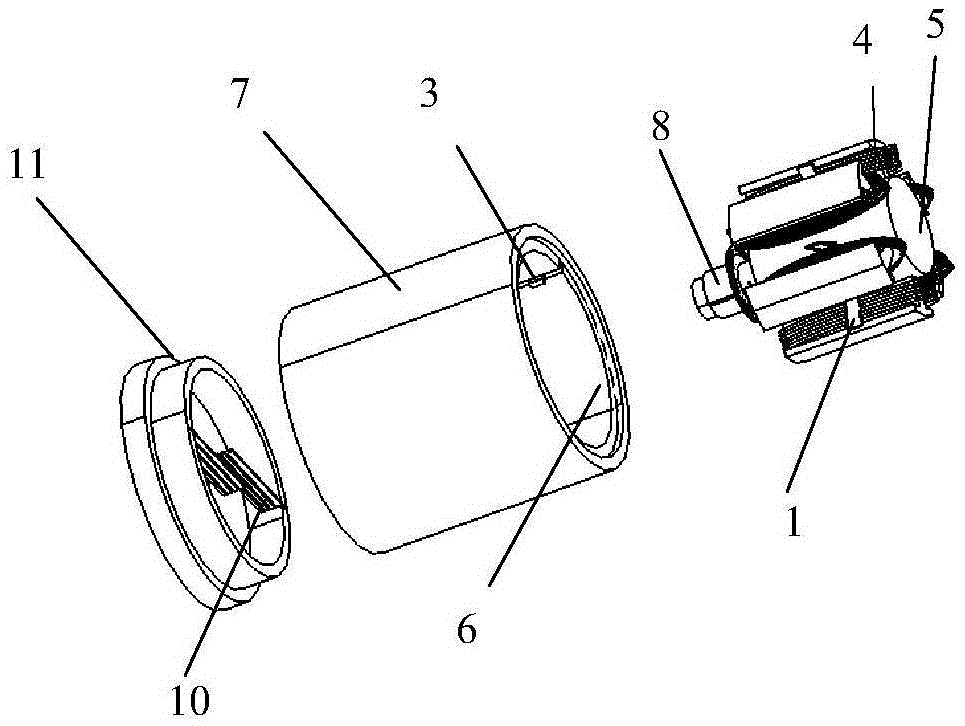

[0026] like Figure 1 to Figure 6 As shown, the present embodiment is composed of a piezoelectric-electromagnetic composite power generation mechanism and a planetary gear acceleration mechanism 2, and the piezoelectric-electromagnetic composite power generation mechanism is composed of an electromagnetic power generation unit, a piezoelectric power generation unit, a raised structure 3 and a casing 7, etc. Composition; the electromagnetic generating unit adopts a brushed DC motor structure. The electromagnetic generating unit includes two parts: the stator and the rotor. The stator is composed of two semi-annular magnetic tiles, the main magnetic pole 6, the brush 10, and the end cover 11; the rotor is composed of the armature winding 4. The armature core 5 and the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com