Miniature piezoelectric and capacitance composite vibration energy harvester

An energy harvester and composite vibration technology, which is applied in the directions of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. and other problems, to achieve the effect of improving energy conversion efficiency, broadening the applicable frequency range and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

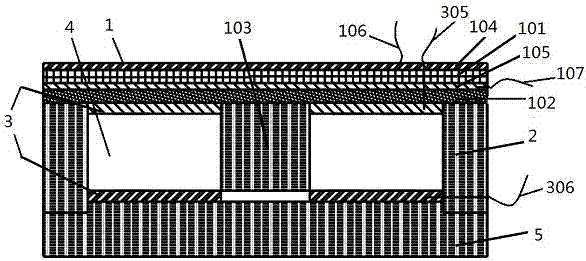

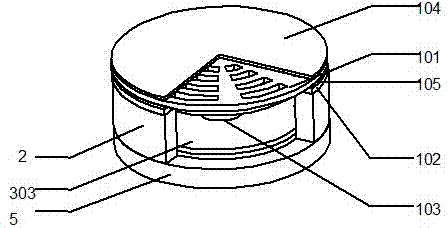

[0037] Such as figure 2 , 3 , 4, the piezoelectric energy collection unit 1 is connected to the upper part of the support body 2, and the bottom part of the support body 2 is bonded on the base body 5, and there is a capacitive energy collection unit 3 inside the support body, and in the capacitive energy collection unit 3 There is an electrolyte 4, and the structure of the piezoelectric energy harvesting unit 1 is: an upper electrode 104 is deposited on the upper part of the spider web piezoelectric film 101, and a lower electrode 105 is deposited on the lower part, and the lower electrode 105 is fixedly connected to the support material 102, and the upper electrode 104 is connected to the The first wire 106 is connected, and the lower electrode 105 is connected to the second wire 107; the lower part of the support material 102 in the piezoelectric energy collection unit 1 is fixedly connected to the quality block 103; the capacitive energy collection unit 3 includes an uppe...

Embodiment 2

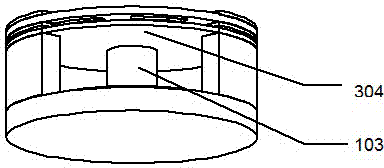

[0039] Such as Figure 5 , 6 , 7, the surface of the upper pole plate 304 and the lower pole plate 303 has a spherical microstructure 301, and the rest are the same as in embodiment 1.

Embodiment 3

[0041] Such as Figure 8 , 9 , 10, the surface of the upper pole plate 304 and the lower pole plate 303 has a pyramidal microstructure 302, and the rest are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com