Industrial production process of high-strength self-compacting concrete

A technology of self-compacting concrete and production process, applied in the field of concrete production and processing, can solve the problems of reducing the overall strength of concrete and the existence of cement aggregates, and achieve the effects of improving the distribution form of hydration products, improving the uniformity and improving the overall structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

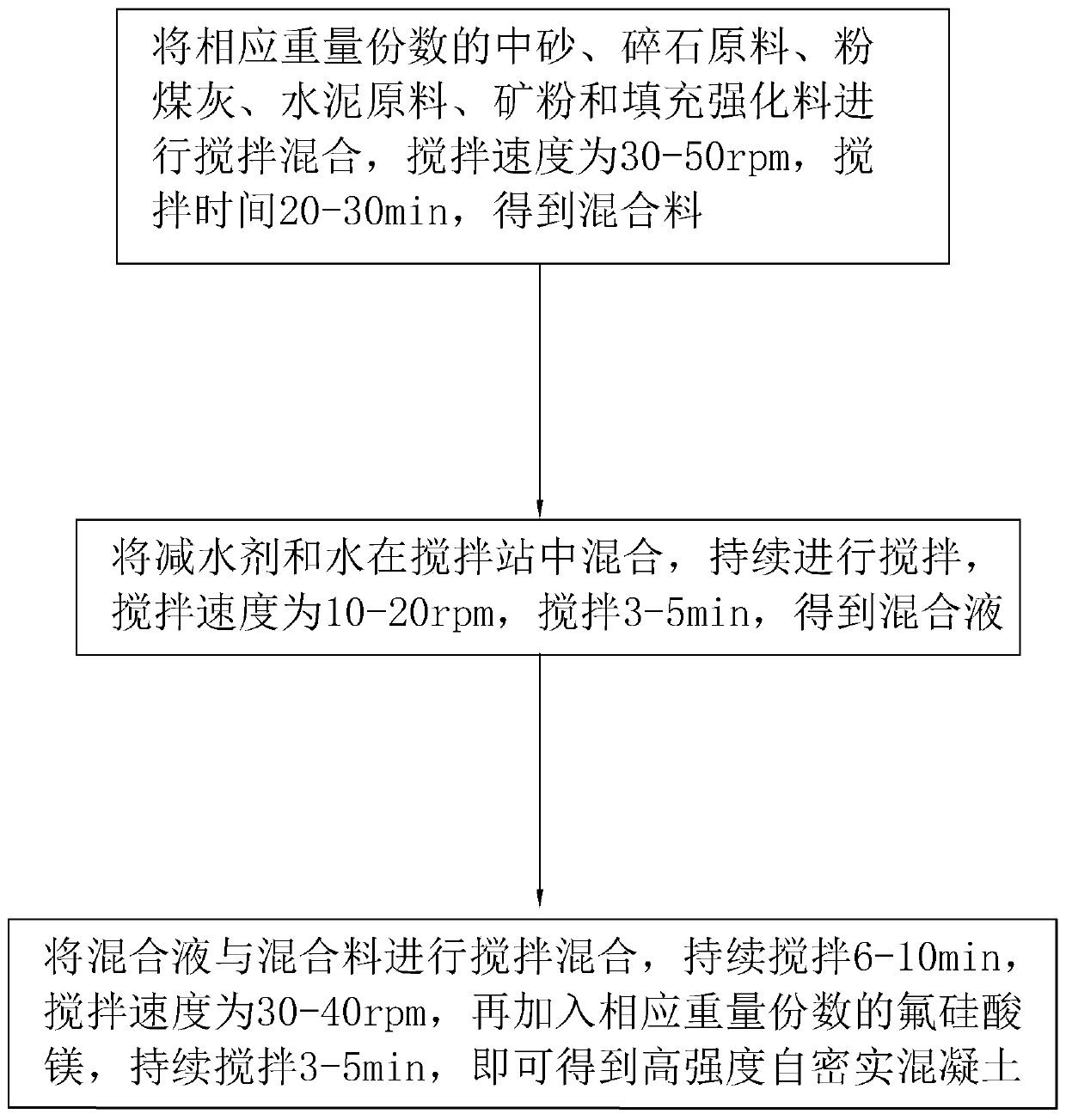

Method used

Image

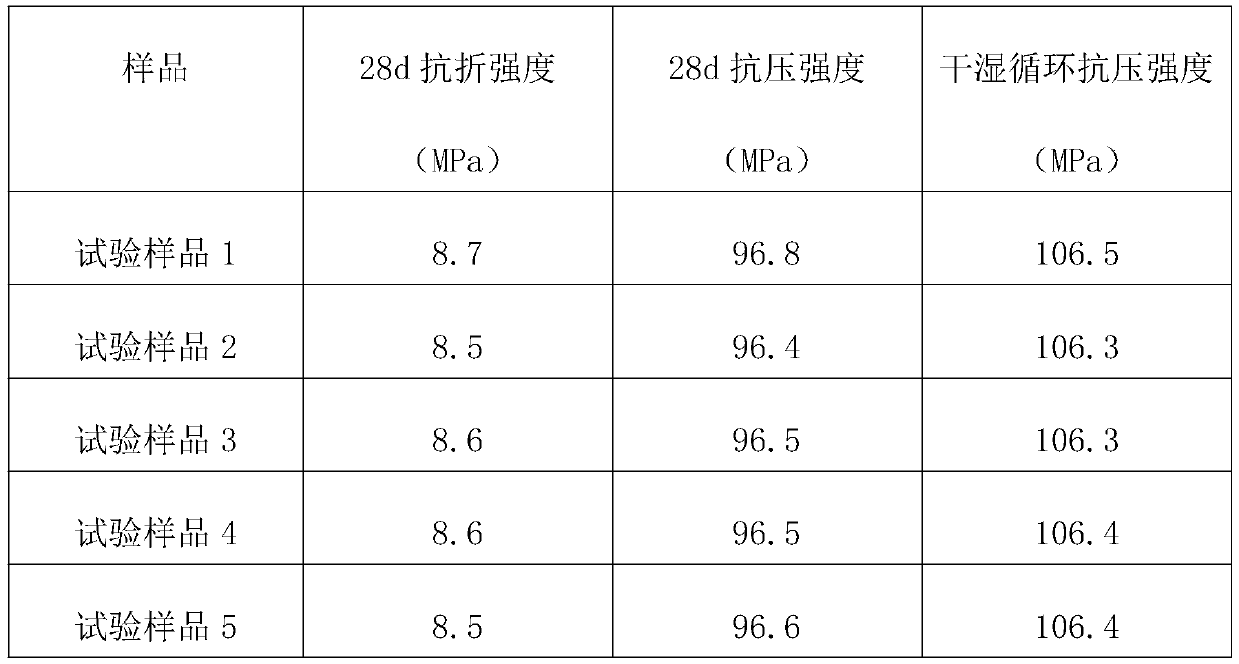

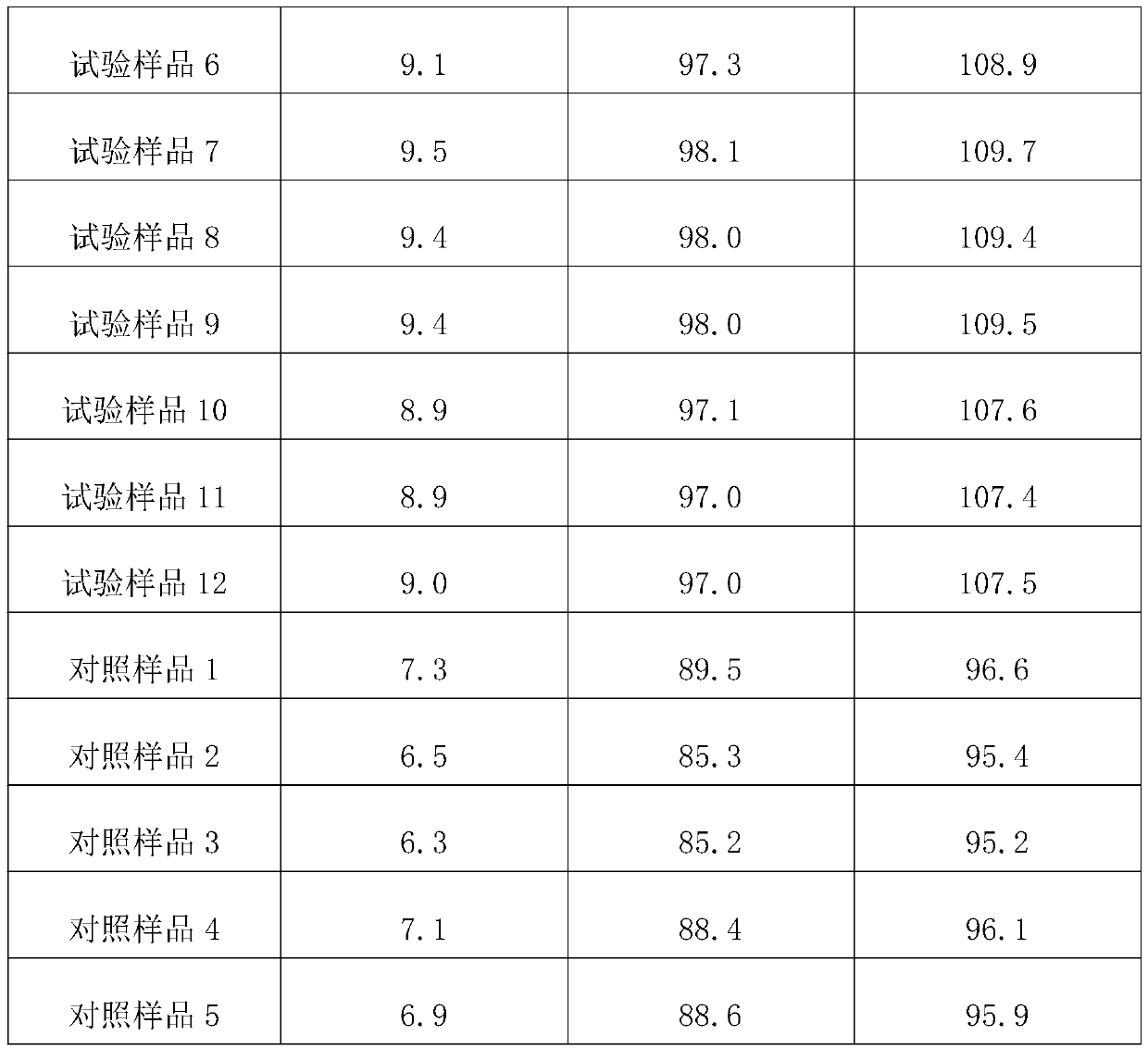

Examples

Embodiment 1

[0033] Embodiment 1: A kind of high-strength self-compacting concrete industrialized production process specifically comprises the following steps: Step 1, raw material preparation, prepares the strength self-compacting concrete raw material of following weight parts: 550 parts of cement raw materials, 70 parts of fly ash, 60 parts of mineral powder, 160 parts of water, 790 parts of medium sand, 800 parts of gravel and 19 parts of admixture;

[0034]Step 2, mixing the slurry, mixing the corresponding parts by weight of cement, fly ash, mineral powder and 20-30% by weight of water, the stirring speed is 50rpm, and the stirring time is 60s to obtain the slurry;

[0035] Step 3, preparing the slurry, adding gravels in corresponding parts by weight to the slurry obtained in step 2, mixing evenly, the stirring speed is 40rpm, and the stirring time is 70s to obtain the slurry;

[0036] Step 4, prepare the mixture, add the corresponding parts by weight of medium sand, admixture and w...

Embodiment 2

[0039] Embodiment 2: A kind of industrialized production process of high-strength self-compacting concrete, differs from Embodiment 1 in that it specifically includes the following steps:

[0040] Step 1, raw material preparation, preparation of the strength self-compacting concrete raw material of following parts by weight: 540 parts of cement raw material, 65 parts of fly ash, 55 parts of mineral powder, 150 parts of water, 780 parts of medium sand, 790 parts of crushed stone and additional 18 doses;

[0041] Step 2, mixing the slurry, mixing the corresponding parts by weight of cement, fly ash, mineral powder and 20-30% by weight of water, the stirring speed is 50rpm, and the stirring time is 60s to obtain the slurry;

[0042] Step 3, preparing the slurry, adding gravels in corresponding parts by weight to the slurry obtained in step 2, mixing evenly, the stirring speed is 40rpm, and the stirring time is 70s to obtain the slurry;

[0043] Step 4, prepare the mixture, add t...

Embodiment 3

[0045] Embodiment 3: A kind of industrialized production process of high-strength self-compacting concrete, the difference from Embodiment 1 is that it specifically includes the following steps:

[0046] Step 1, raw material preparation, preparation of the strength self-compacting concrete raw material of following parts by weight: 560 parts of cement raw materials, 75 parts of fly ash, 65 parts of mineral powder, 170 parts of water, 800 parts of medium sand, 810 parts of crushed stone and additional 20 doses;

[0047] Step 2, mixing the slurry, mixing the corresponding parts by weight of cement, fly ash, mineral powder and 20-30% by weight of water, the stirring speed is 50rpm, and the stirring time is 60s to obtain the slurry;

[0048] Step 3, preparing the slurry, adding gravels in corresponding parts by weight to the slurry obtained in step 2, mixing evenly, the stirring speed is 40rpm, and the stirring time is 70s to obtain the slurry;

[0049] Step 4, prepare the mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com