Preparation method of anti-freezing cement mortar with rice husk ash and silica fume

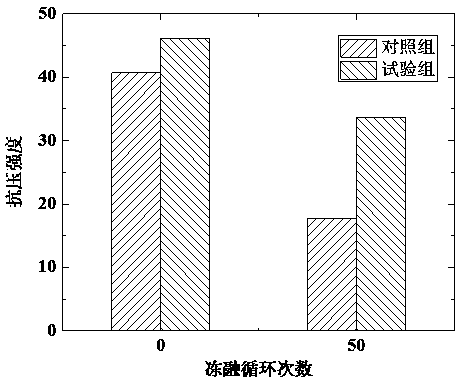

A technology for cement mortar and rice husk ash, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of insufficient frost resistance and durability of cement mortar, so as to solve the problem of frost resistance and improve durability. Strength, frost resistance, and effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0024] Specific embodiment 1: This embodiment records a method for preparing antifreeze cement mortar with double mixing of rice husk ash and silica fume. The specific steps of the method are as follows:

[0025] Step 1: High-temperature calcination: Place the natural rice husk in a muffle furnace and calcine at 800°C for 2 hours to obtain rice husk ash;

[0026] Step 2: Ball milling: Put the rice husk ash obtained in Step 1 into a planetary ball mill tank and equip it with steel balls, and mill it at a speed of 300r / min for 2h;

[0027] Step 3: Proportioning: take materials according to weight fraction, 100 parts of cement, 8.33 parts of rice husk ash obtained in step 2, 16.67 parts of silica fume, 375 parts of standard sand, and 62.5 parts of water;

[0028] Step 4: Mixing and stirring: Add water, cement, rice husk ash, silica fume, and standard sand to the mixing pot in sequence, and mix evenly to obtain a mixture;

[0029] Step 5: Vibration: Pour the mixture obtained in step 4 into ...

specific Embodiment approach 2

[0031] Specific embodiment two: the preparation method of double-mixed rice husk ash and silica fume antifreeze cement mortar described in specific embodiment 1, in step 2, the added amount of rice husk ash accounts for 75% of the volume of the planetary ball mill tank %.

specific Embodiment approach 3

[0032] Specific embodiment three: The preparation method of a double-mixed rice husk ash and silica fume antifreeze cement mortar described in specific embodiment 1, in step 2, the steel balls are composed of 200 large balls with a diameter of 10 mm and 1,000 It consists of a small ball with a diameter of 6mm.

[0033] Specific embodiment four: the preparation method of a double-mixed rice husk ash and silica fume antifreeze cement mortar described in specific embodiment 1, in step four, the mixing and stirring are specifically: first putting water into a mixing pot , Then add cement, rice husk ash and silica fume, mix at low speed for 30s; then pour standard sand into the mixing pot, stir at low speed for 30s while pouring, clean the mortar on the blades and pot wall; finally, mix at high speed for 30s; The low-speed rotation speed described in the above two places is 140 r / min and 62 r / min; the high-speed rotation speed is 285 r / min and 125 r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com