High-performance grouting material for prefabricated buildings and preparation method thereof

A high-performance, construction technology, applied in the field of building materials, can solve the problems of insufficient corrosion protection of steel bars, large shrinkage, low tensile and flexural strength, etc., to avoid slow strength growth or even collapse, and improve flexural strength. And the effect of rapid and stable development of fracture toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 10

[0061] Embodiment 1 to embodiment 10 are prepared according to the following method:

[0062] Step 1: Mix the modified nanomaterial, dispersant and water, stir, carry out ultrasonic dispersion, wash and dry, and then grind into powder in a ball mill to obtain performance regulator powder for use.

[0063] Step 2: mixing and stirring the composite cementitious material, graded fine sand and additives to obtain a mixture.

[0064] Step 3: Add the performance modifier powder obtained in Step 1 to the mixture prepared in Step 2, and stir until uniform to obtain a dry powder of high-performance grouting material.

[0065] Step 4: Mix the dry powder prepared in step 3 with an appropriate amount of water, and stir to obtain.

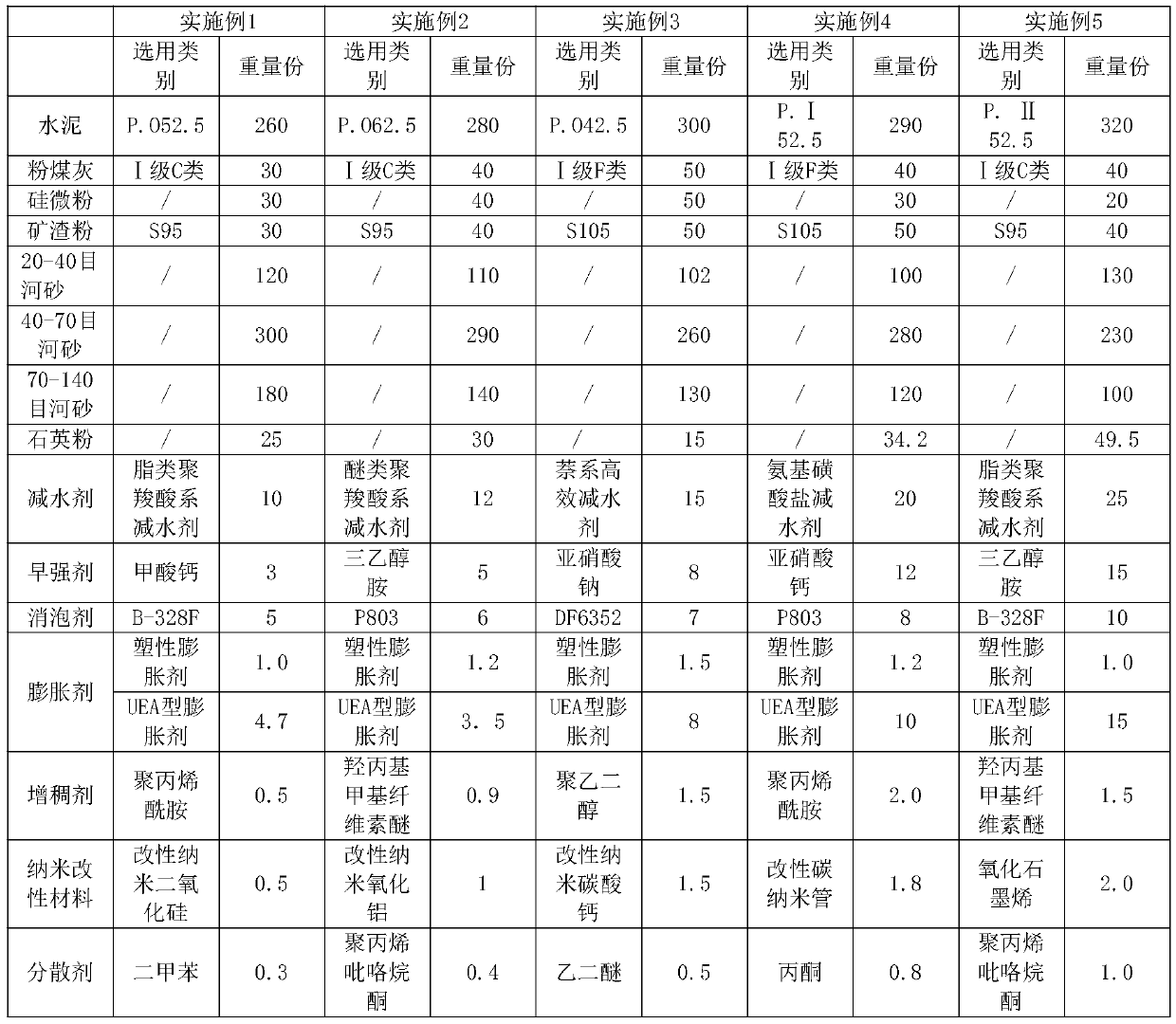

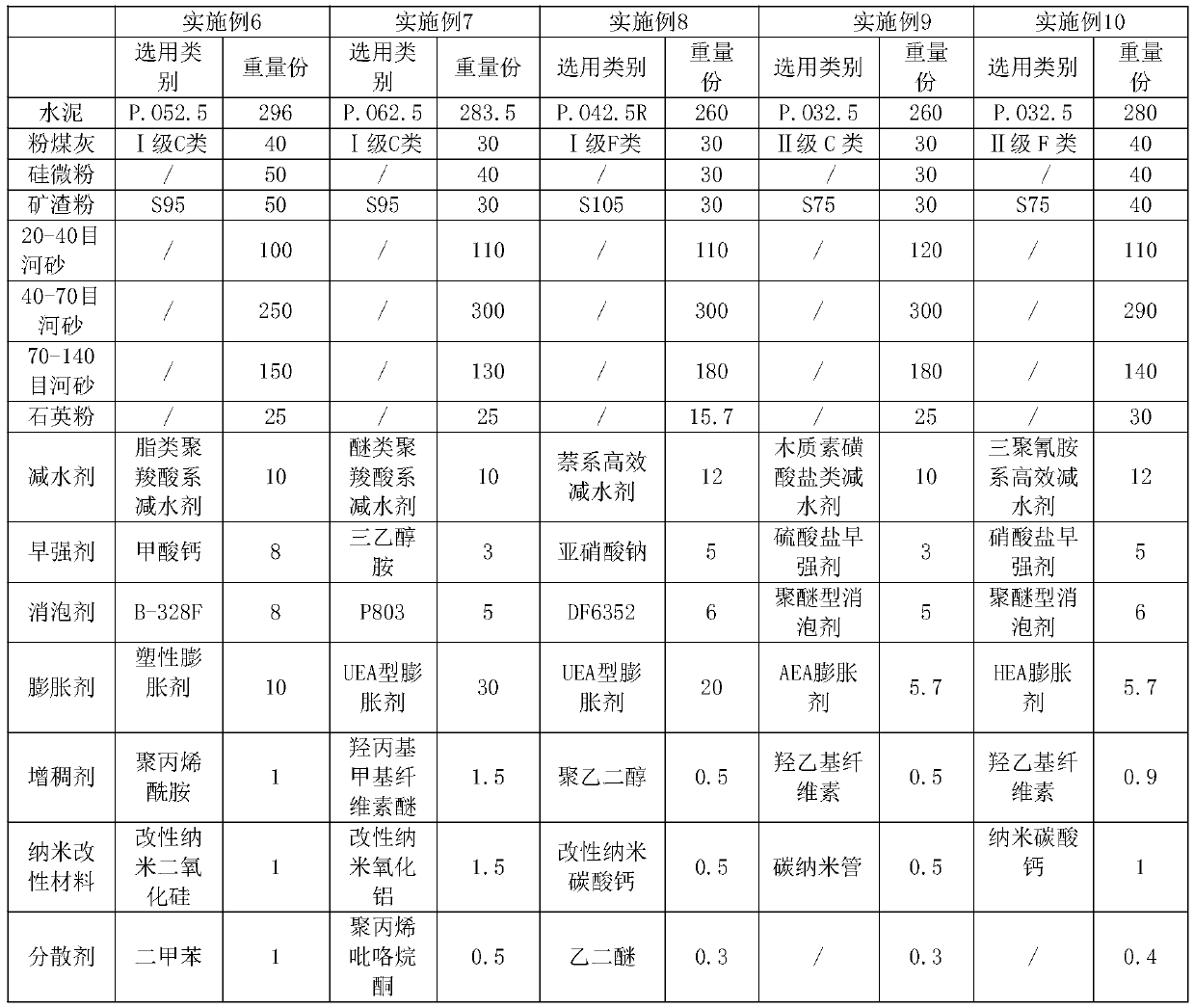

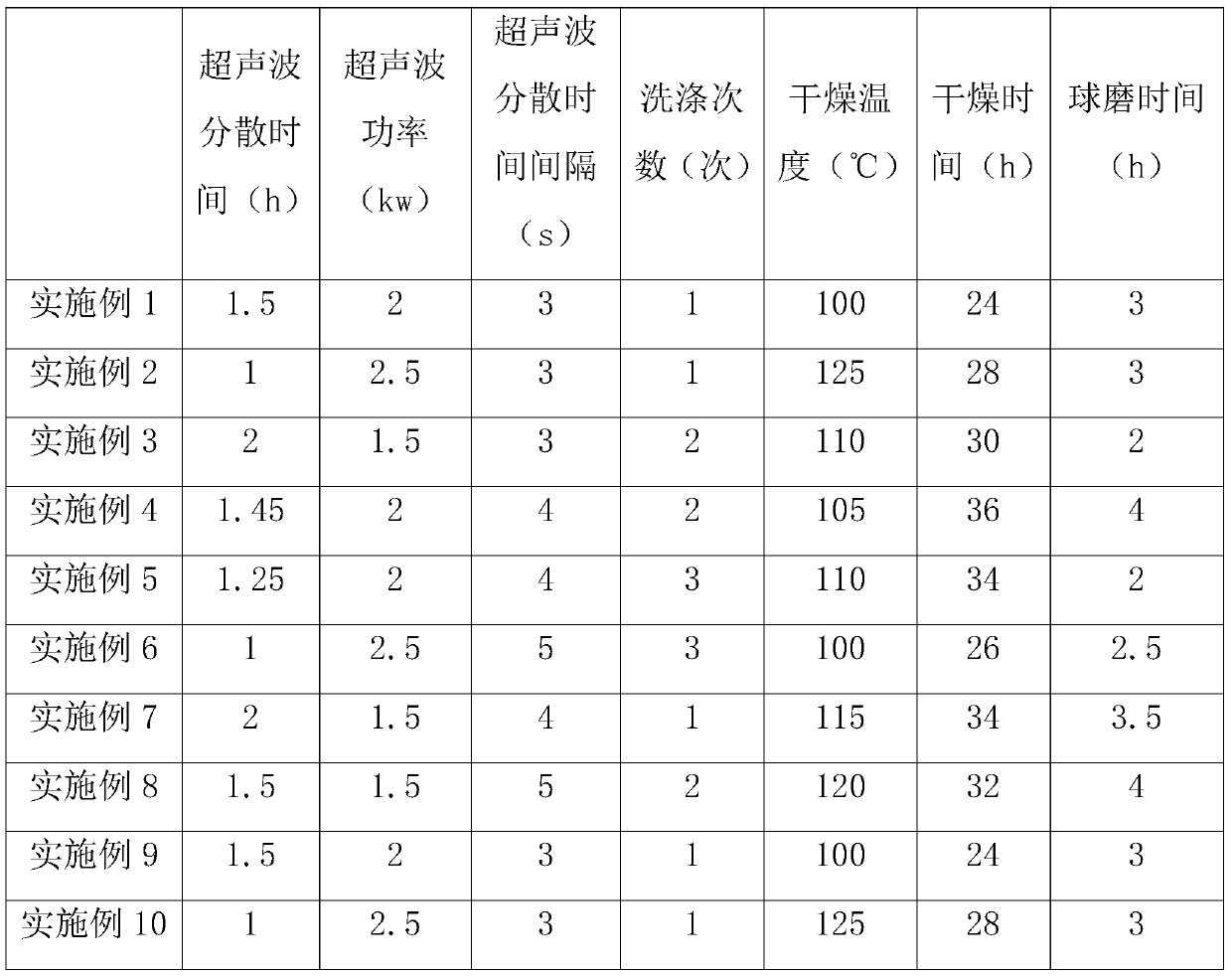

[0066] Among them, the specific parameters used in each step are shown in Table 3 and Table 4.

[0067] Table 3: Example 1 to 10 step 1 preparation parameter table

[0068]

[0069] According to the operation of the above steps and parameters, the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com