A method for reinforced concrete work construction in cold winter

A reinforced concrete and engineering construction technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as great impact, great impact on building construction quality and project construction progress, and inability of concrete to solidify effectively. The effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

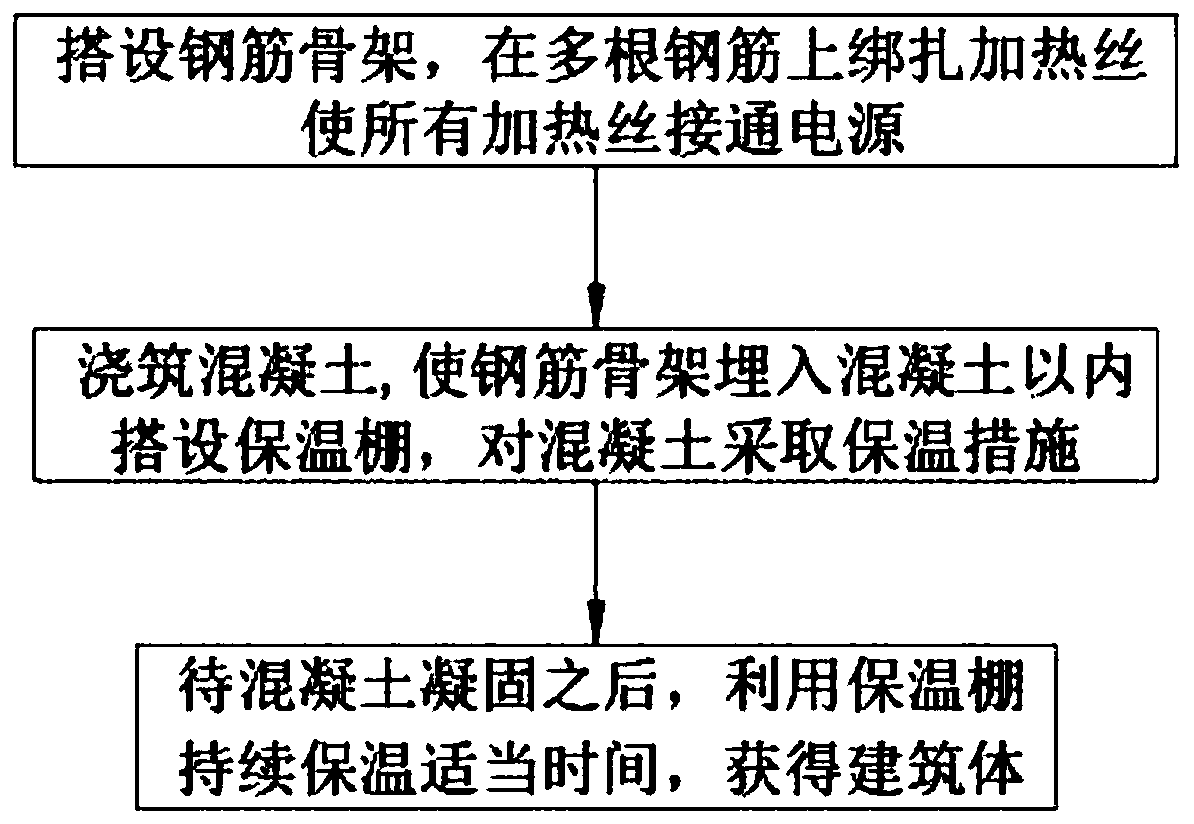

[0021] The invention provides a construction method for reinforced concrete engineering in cold winter, such as figure 1 shown, including the following steps:

[0022] Step 1: Deploy multiple steel bars along multiple different directions on the construction site. Bind any two steel bars at their staggered joints so that all steel bars connect to form a steel skeleton, and then select several steel bars as heat-conducting steel bars. Bind heating wires on the heat-conducting steel bars, and connect all the heating wires to a power supply; preferably, the power supply in step 1 is a sine wave alternating current with an effective voltage of 220 volts. When the heating wire described in step 1 works at the rated voltage, its surface temperature is 4°C to 10°C.

[0023] Step 2: pouring concrete, so that the reinforcement skeleton de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com