High-strength heat-resistant concrete and preparation method thereof

A heat-resistant concrete, high-strength technology, applied in the field of building materials, can solve problems such as unfavorable durability, low flexural strength, and reduced strength, achieve good impermeability, improve mechanical properties and heat resistance, and improve later strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

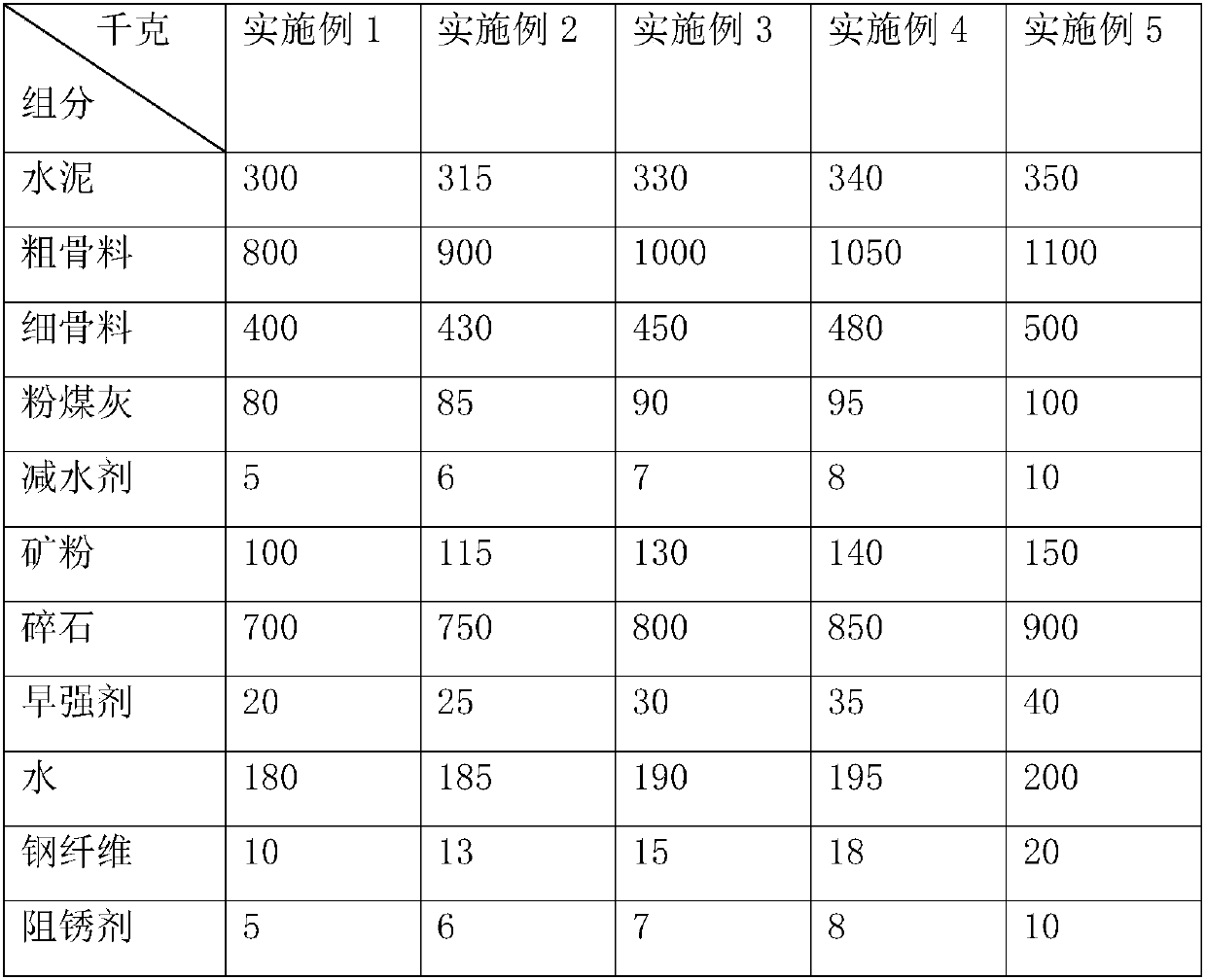

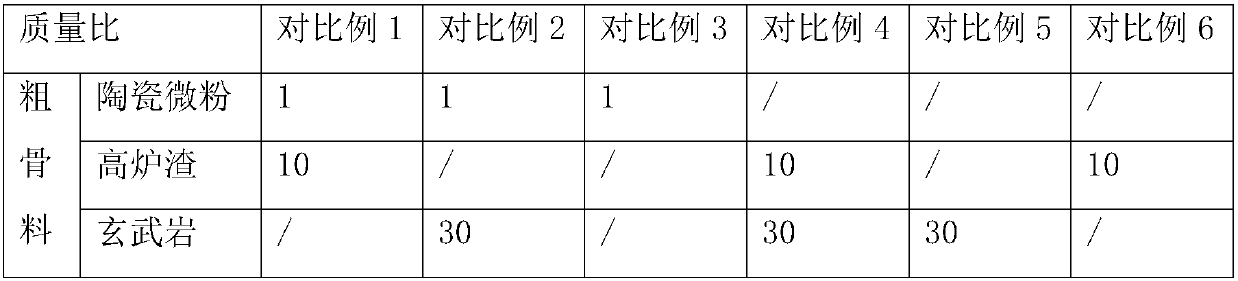

Examples

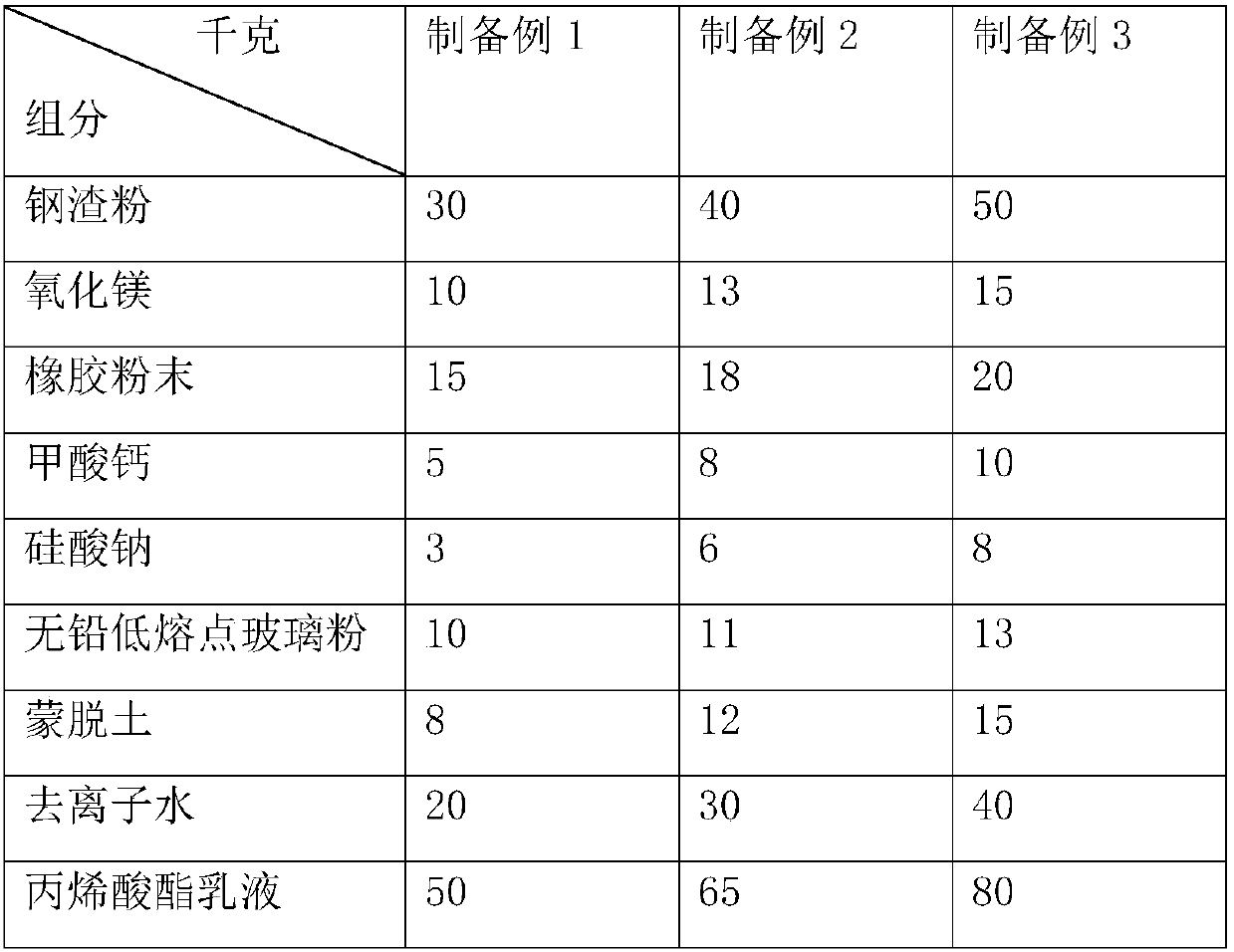

preparation example 1-3

[0041] In the preparation example 1-3, the sodium silicate is selected from the sodium silicate sold by Jinan Xinsenyuan Chemical Co., Ltd. with the product number of 668, and the calcium formate is selected from the HBL-J30 calcium formate and magnesium oxide sold by Zhengzhou Hongboli Chemical Products Co., Ltd. Choose from ZH-V3H type magnesium oxide sold by Suzhou Zemei New Material Technology Co., Ltd., acrylate emulsion from BA-201 type acrylate emulsion sold by Jining Baichuan Chemical Co., Ltd., lead-free low-melting glass powder from Guangzhou Song The D240, D250 and D270 lead-free low-melting glass powders sold by Liner New Materials Co., Ltd., the steel slag powder is selected from the steel slag powder with the item number 05 sold by Lingshou County Bailing Mineral Products Processing Factory, and the rubber powder is selected from Huayi, Dujiangyan City The rubber powder sold by Rubber Co., Ltd. is xjf-003, and the montmorillonite is selected from the WSG-PN06 plas...

preparation example 1

[0042] Preparation Example 1: (1) According to the proportioning in Table 1, heat 20kg of deionized water to 80°C, add 5kg of calcium formate, 3kg of sodium silicate and 10kg of magnesium oxide to the deionized water, at a speed of 600r / min Stir for 20min and keep warm at 80°C for 1h; (2) Stir 30kg steel slag powder, 15kg rubber powder, 8kg montmorillonite and 10kg lead-free low-melting glass powder at 1000r / min for 2h, the particle size of steel slag powder is 5- 15cm continuous gradation, the particle size of rubber powder is 20mm, the particle size of montmorillonite is 25mm, the particle size of lead-free low-melting glass powder is 1μm, and the melting point is 400℃;

[0043] (3) Add the result of step (1) to 50kg of acrylate emulsion, stir at 1000r / min for 40min, then add the result of step (2), and ultrasonically disperse for 30min, the ultrasonic dispersion power is 35kW.

[0044] The raw material ratio of early strength agent in table 1 preparation example 1-3

[004...

preparation example 2

[0046] Preparation Example 2: (1) According to the proportioning in Table 1, heat 30kg of deionized water to 85°C, add 8kg of calcium formate, 6kg of sodium silicate and 13kg of magnesia to the deionized water, at a speed of 700r / min Stir for 25 minutes and keep warm at 85°C for 1.5 hours;

[0047] (2) Stir 40kg steel slag powder, 18kg rubber powder, 12kg montmorillonite and 11kg lead-free low-melting glass powder at 1200r / min for 2.5h, the particle size of steel slag powder is a continuous gradation of 5-15cm, the rubber powder The particle size is 25mm, the particle size of montmorillonite is 25mm, the particle size of lead-free low-melting glass powder is 5μm, and the melting point is 500°C;

[0048] (3) Add the result of step (1) to 65kg of acrylate emulsion, stir at 1300r / min for 50min, then add the result of step (2), and ultrasonically disperse for 35min, the ultrasonic dispersion power is 40kW.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com