Production process for high-strength high-volume phosphogypsum baking-free brick

A production process, phosphogypsum technology, applied in the field of building materials, can solve problems such as large heat consumption, high energy consumption, and secondary pollution of the atmosphere, and achieve the effects of improving resource utilization efficiency, high dosage, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

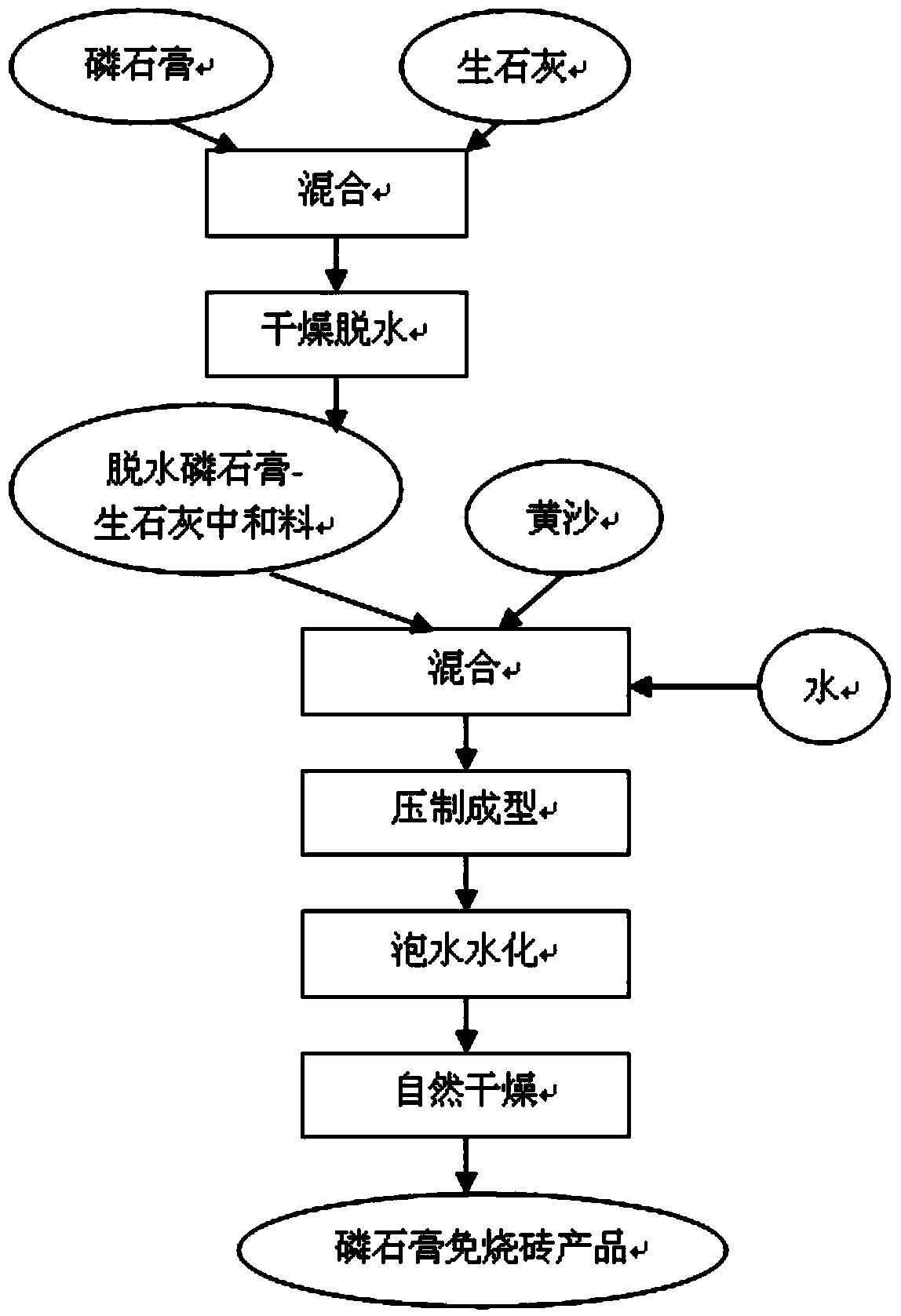

[0039] Process flow chart such as figure 1 Shown, the production technology of the present embodiment comprises the following steps:

[0040] (1) Raw material pretreatment: first mix phosphogypsum and quicklime at a mass ratio of 100:2, and stale for 1 day so that the residual acid in phosphogypsum is fully neutralized by quicklime; then place the mixture in a drying machine Drying and dehydration treatment at 180°C and normal pressure for 1 hour to obtain dehydrated phosphogypsum-quicklime neutralizing material;

[0041] (2) Ingredients: Weigh dehydrated phosphogypsum-quicklime neutralizer and yellow sand, and the mass percentages of the two raw materials are: 80% dehydrated phosphogypsum-quicklime neutralizer, 20% yellow sand, and put them into the mixer to stir and mix Evenly, the batch material is prepared;

[0042] (3) Stirring with water: add water to the batch, the mass ratio of the batch to water is 100:22, fully stir and mix to obtain the water-mixed batch;

[0043...

Embodiment 2

[0048] The production technique of the present embodiment comprises the following steps:

[0049] (1) Raw material pretreatment: first mix phosphogypsum and quicklime at a mass ratio of 100:2, and stale for 1 day so that the residual acid in phosphogypsum is fully neutralized by quicklime; then place the mixture in a drying machine Drying and dehydration treatment at 180°C and normal pressure for 1 hour to obtain dehydrated phosphogypsum-quicklime neutralizing material;

[0050] (2) Ingredients: Weigh dehydrated phosphogypsum-quicklime neutralizing material and yellow sand, and the mass percentages of the two raw materials are: 90% dehydrated phosphogypsum-quicklime neutralizing material, 10% yellow sand, and put them into the mixer to stir and mix Evenly, the batch material is prepared;

[0051] (3) Stirring with water: add water to the batch, the mass ratio of the batch to water is 100:25, fully stir and mix to obtain the water-mixed batch;

[0052] (4) Compression forming...

Embodiment 3

[0057] The production technique of the present embodiment comprises the following steps:

[0058] (1) Raw material pretreatment: first mix phosphogypsum and quicklime at a mass ratio of 100:2, and stale for 1 day so that the residual acid in phosphogypsum is fully neutralized by quicklime; then place the mixture in a drying machine Drying and dehydration treatment at 180°C and normal pressure for 1 hour to obtain dehydrated phosphogypsum-quicklime neutralizing material;

[0059] (2) Ingredients: Weigh dehydrated phosphogypsum-quicklime neutralizing material and yellow sand, and the mass percentages of the two raw materials are: 70% dehydrated phosphogypsum-quicklime neutralizing material, 30% yellow sand, and put them into the mixer to stir and mix Evenly, the batch material is prepared;

[0060] (3) Stirring with water: add water to the batch, the mass ratio of the batch to water is 100:18, fully stir and mix to obtain the water-mixed batch;

[0061] (4) Compression molding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com