High-strength anti-crack concrete and preparation method thereof

A concrete and high-strength technology, applied in the field of high-strength crack-resistant concrete and its preparation, can solve problems such as low bonding strength and insufficient hydration, improve crack resistance and overall strength, increase overall strength, and reduce the risk of cracking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

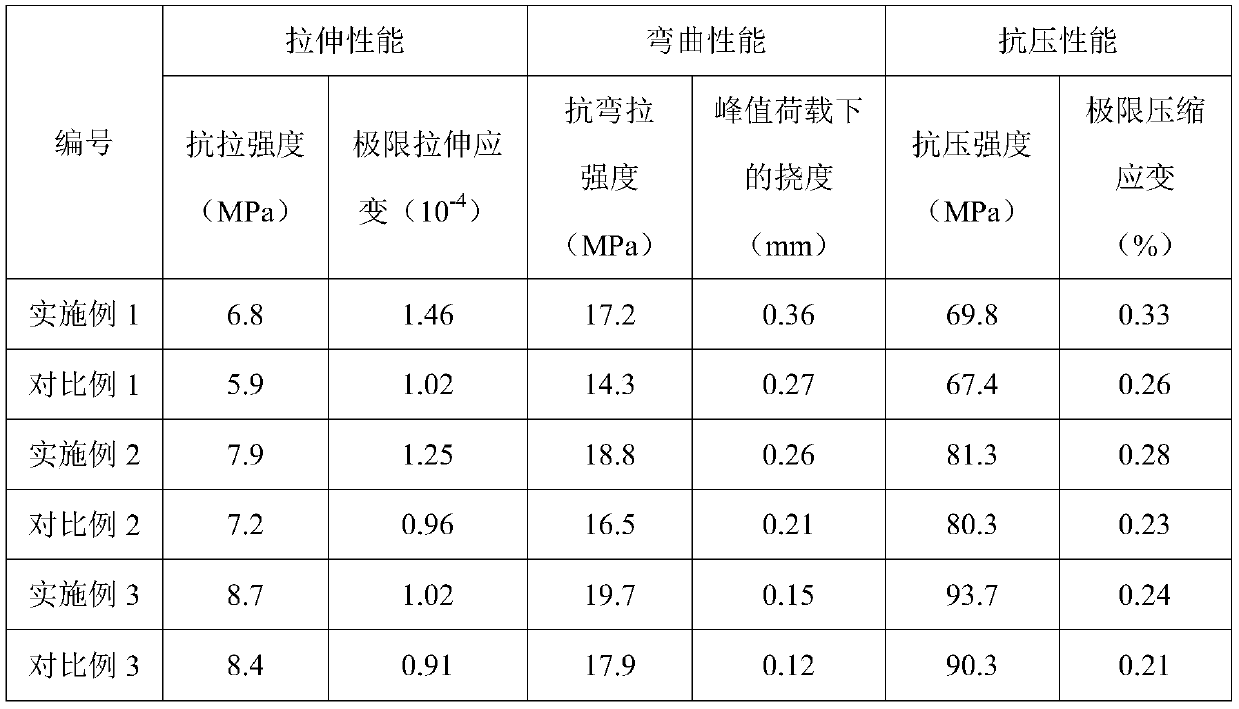

Examples

Embodiment 1

[0048] The invention provides a lightweight ultra-high-strength concrete and a preparation method thereof.

[0049] A high-strength crack-resistant concrete, in parts by weight, comprising the following raw materials:

[0050] General portland cement, 460 parts;

[0051] Fly ash, 50 parts;

[0052] Silica fume, 40 parts;

[0053] Coarse aggregate, 1050 parts;

[0054] Fine aggregate, 580 parts;

[0055] Modified waste ABS plastic particles, 140 parts;

[0056] Modified zeolite powder, 50 parts

[0057] Polypropylene fiber, 0.6 part;

[0058] Polycarboxylate superplasticizer, 15.5 parts;

[0059] Water-binder ratio, 0.25.

[0060] in:

[0061] Portland cement is ordinary Portland cement with a strength of 42.5 MPa.

[0062] Fly ash is superfine fly ash with an average particle size of 2.7 μm.

[0063] The specific surface area of silica fume is ≥20000m 2 / kg, average particle size 0.14μm.

[0064] Coarse aggregate is 5-25mm continuous graded crushed stone.

[0065...

Embodiment 2

[0076] Provided are a lightweight ultra-high-strength concrete and a preparation method thereof.

[0077] A high-strength crack-resistant concrete, in parts by weight, comprising the following raw materials:

[0078] General portland cement, 480 parts;

[0079] Fly ash, 60 parts;

[0080] Silica fume, 50 parts;

[0081] Coarse aggregate, 1050 parts;

[0082] Fine aggregate, 590 parts;

[0083] Modified waste ABS plastic particles, 150 parts;

[0084] Modified zeolite powder, 60 parts

[0085] Polypropylene fiber, 0.7 part;

[0086] Polycarboxylate superplasticizer, 16.2 parts;

[0087] Water-binder ratio, 0.23.

[0088] in:

[0089] Portland cement is ordinary Portland cement with a strength of 42.5 MPa.

[0090] Fly ash is superfine fly ash with an average particle size of 2.9 μm.

[0091] The specific surface area of silica fume is ≥20000m 2 / kg, average particle size 0.17μm.

[0092] Coarse aggregate is 5-25mm continuous graded crushed stone.

[0093] Fine a...

Embodiment 3

[0104] The invention provides a lightweight ultra-high-strength concrete and a preparation method thereof.

[0105] A high-strength crack-resistant concrete, in parts by weight, comprising the following raw materials:

[0106] General portland cement, 500 parts;

[0107] Fly ash, 60 parts;

[0108] Silica fume, 50 parts;

[0109] Coarse aggregate, 1150 parts;

[0110] Fine aggregate, 580 parts;

[0111] Modified waste ABS plastic particles, 160 parts;

[0112] Modified zeolite powder, 50 parts

[0113] Polypropylene fiber, 0.8 parts;

[0114] Polycarboxylate superplasticizer, 16.9 parts;

[0115] Water-binder ratio, 0.20.

[0116] in:

[0117] Portland cement is ordinary Portland cement with a strength of 42.5 MPa.

[0118] Fly ash is superfine fly ash with an average particle size of 3.1 μm.

[0119] The specific surface area of silica fume is ≥20000m 2 / kg, with an average particle size of 0.19 μm.

[0120] Coarse aggregate, 5-25mm continuous graded crushed st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com