Full width weft insertion device installed on small diameter round warp knitting machine

A full-width weft insertion and warp knitting machine technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the effects of performance such as strength, stiffness, shear resistance and impact resistance, low molding efficiency, and production costs. Advanced problems, to achieve the effect of easy production management, improved performance, improved shear resistance and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

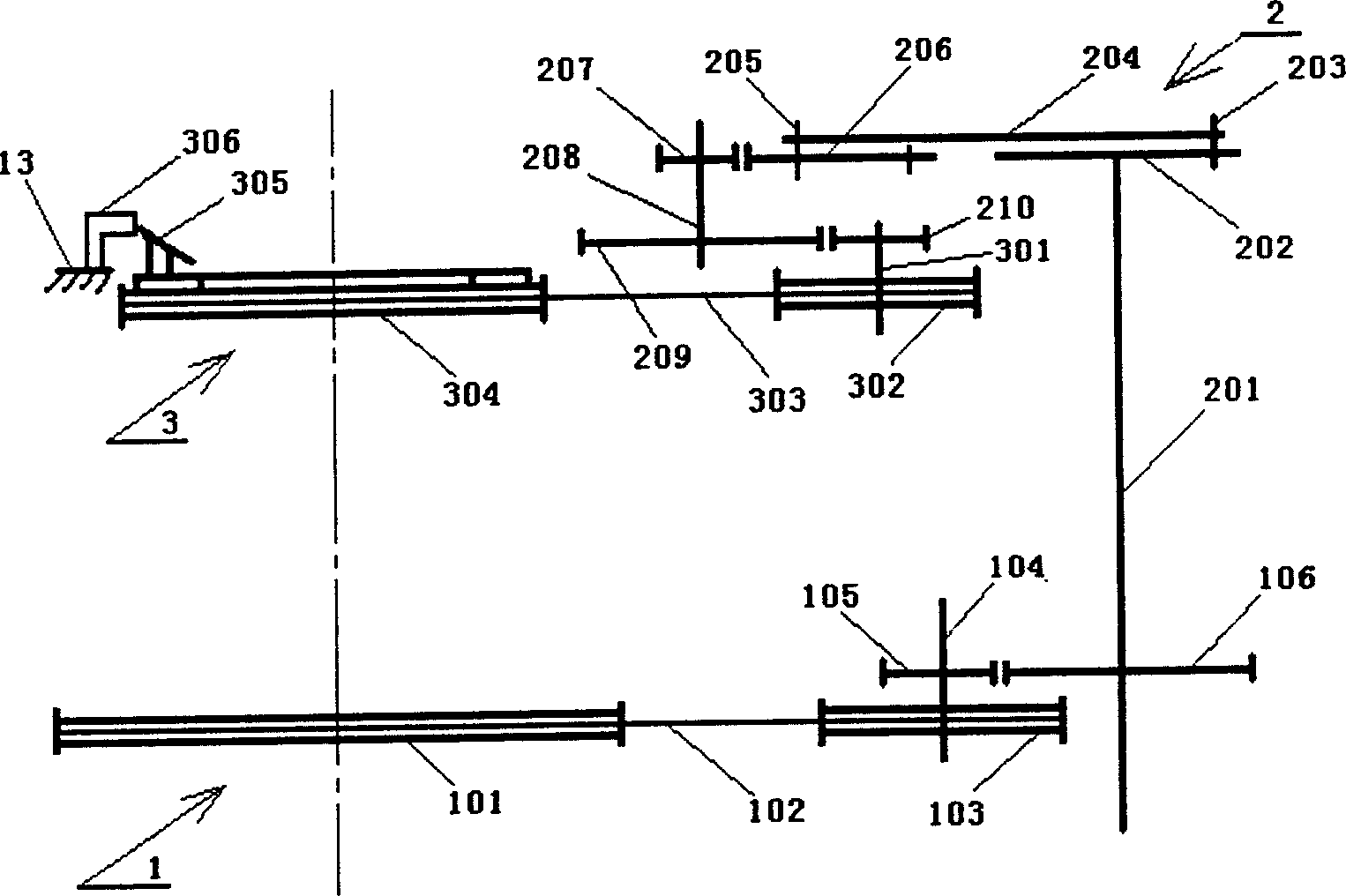

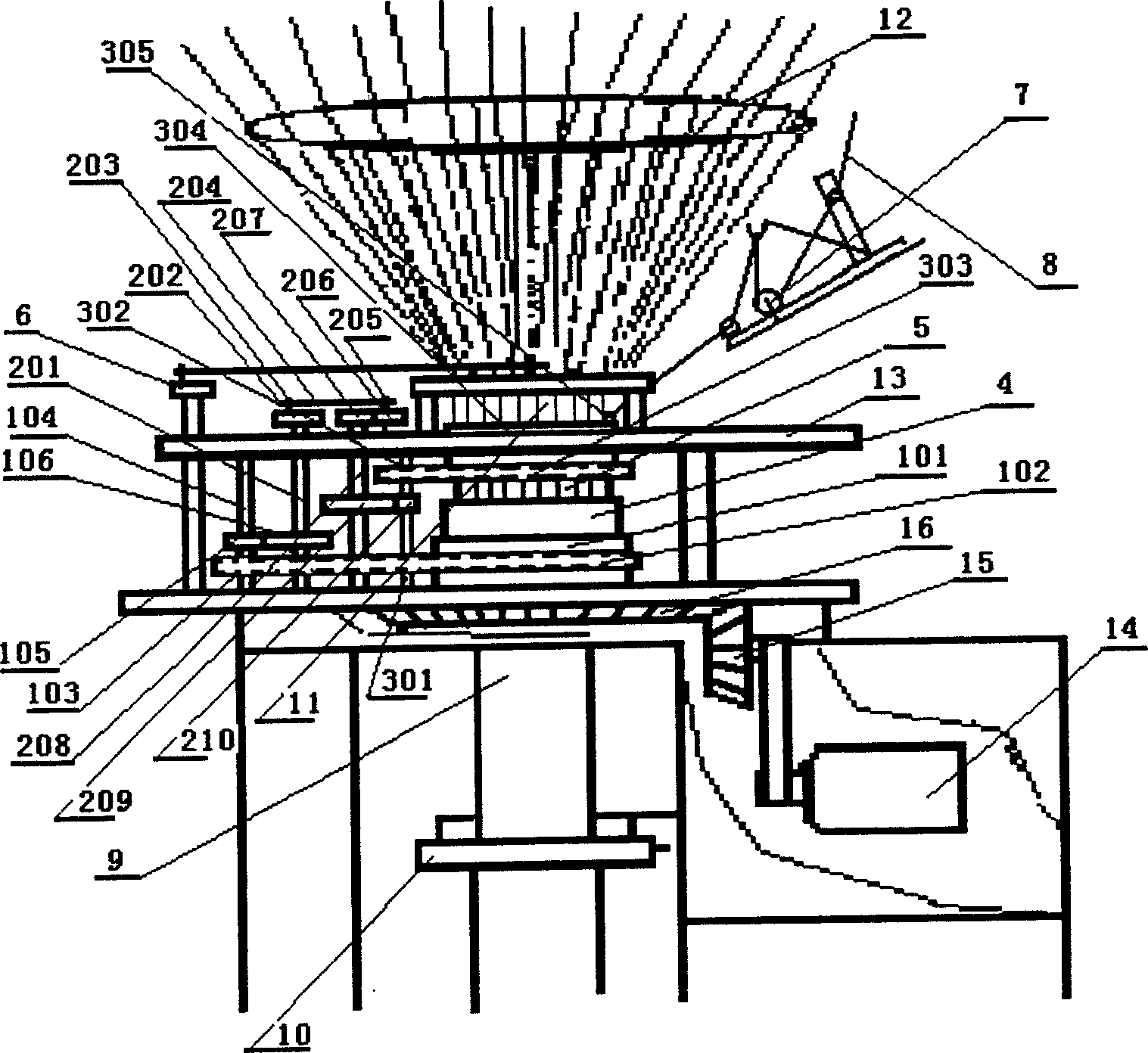

[0017] see figure 1 and figure 2 As shown, a full-width weft insertion device installed on a small-diameter circular warp knitting machine of the present invention includes a synchronous transmission device 1 , a reciprocating conversion and speed change device 2 and a full-width weft insertion guide device 3 . The driving synchronous pulley 101 in the synchronous transmission device 1 is connected with the triangular slewing seat 4, the first transmission belt 102 is looped on the driving synchronous pulley 101 and the driven synchronous pulley 103, and the driven synchronous belt is driven by the driving synchronous pulley 101 Wheel 103, the driven synchronous pulley 103 links to each other with the driving transmission gear 105 through the first coupling shaft 104, and the driven transmission gear 106 is arranged on the lower end of the second coupling shaft 201; The upper end of the second coupling shaft 201, the two ends of the connecting rod 204 are respectively connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com