A hot runner nozzle structure for three-layer material injection molding

A technology of three-layer materials and hot runners, applied in the field of auxiliary structures, to achieve the effects of shortening the process flow, streamlining and saving, saving equipment debugging and material turnover time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

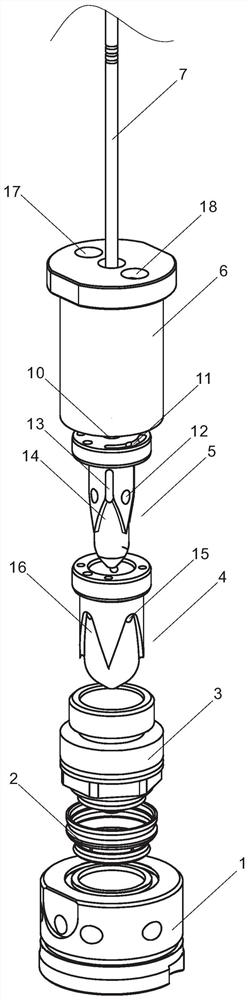

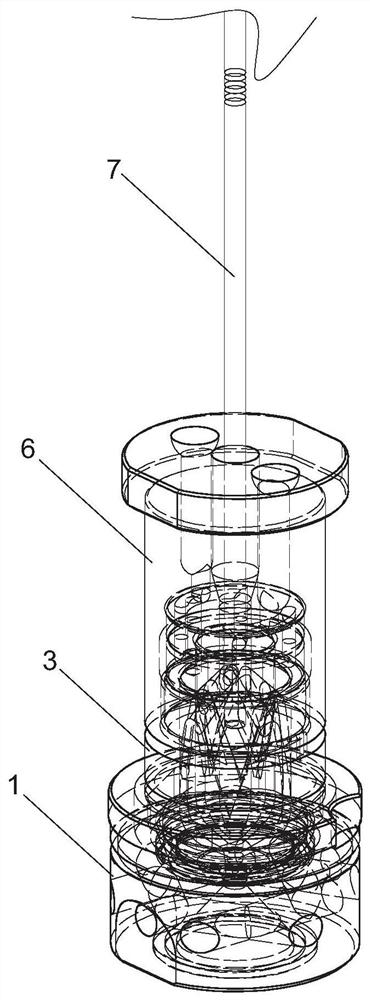

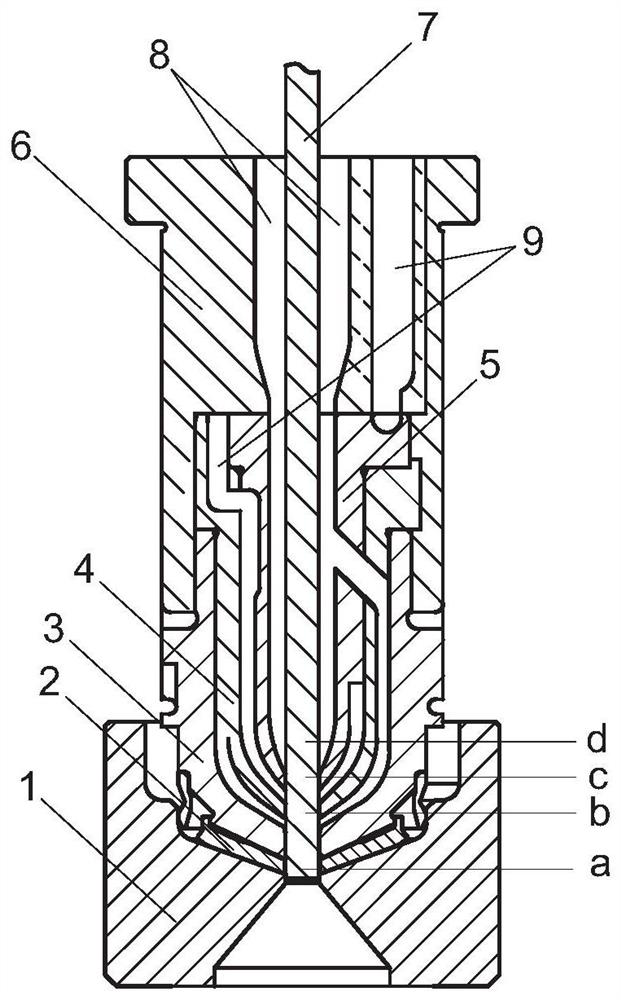

[0026] Such as Figure 1 to Figure 4 As shown, a hot runner nozzle structure of three-layer material injection molding, including cold mold 1, nozzle 3, outer nozzle 4, inner nozzle 5, nozzle seat 6 and valve needle 7, nozzle 3, outer nozzle 4 , the inner nozzle 5 and the nozzle seat 6 are all hollow structures with a central opening at the bottom, the nozzle seat 6, the outer nozzle 4 and the inner nozzle 5 are coaxially nested and matched from the outside to the inside in turn, and the three are provided with a peripheral In the positioning structure, the outer nozzle 4 is coaxially nested and matched with the nozzle 3 at the same time, the nozzle 3 is fixedly connected to the open end of the bottom of the nozzle seat 6, the bottom of the nozzle 3 is embedded in the cavity of the cold mold 1, and the valve needle 7 Along the axis of nozzle 3, outer nozzle 4, inner nozzle 5, and nozzle seat 6, it can slide through the nozzle 3, outer nozzle 4, inner nozzle 5, nozzle seat 6, a...

Embodiment 2

[0029] The present invention is used for bottle caps of glass cans, the base material A is food-grade PP, and the interlayer material B is EVOH. All the other are with embodiment 1.

[0030] When working, after the inner layer of the bottle cap is formed, the valve needle 7 moves directly from the position b above the center opening of the bottom of the nozzle to the position d above the center opening of the bottom of the inner nozzle, and then the bottle cap interlayer and outer layer are formed by controlling the injection pressure.

Embodiment 3

[0032] Interlayer material B is color masterbatch. All the other are with embodiment 1. After the final blow molding of the obtained preform, it has both hygienic safety and high light-shielding performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com