Intermittent production graduation real-time monitoring system and method of hot-mix asphalt mixture

An asphalt mixture, real-time monitoring technology, applied in signal transmission system, comprehensive factory control, comprehensive factory control, etc., can solve the problem of unstable road surface quality, inability to ensure that the mixture gradation is always under control, and poor monitoring of the mixing process and other issues to achieve the effect of reducing the probability of early damage, good economic and social benefits, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

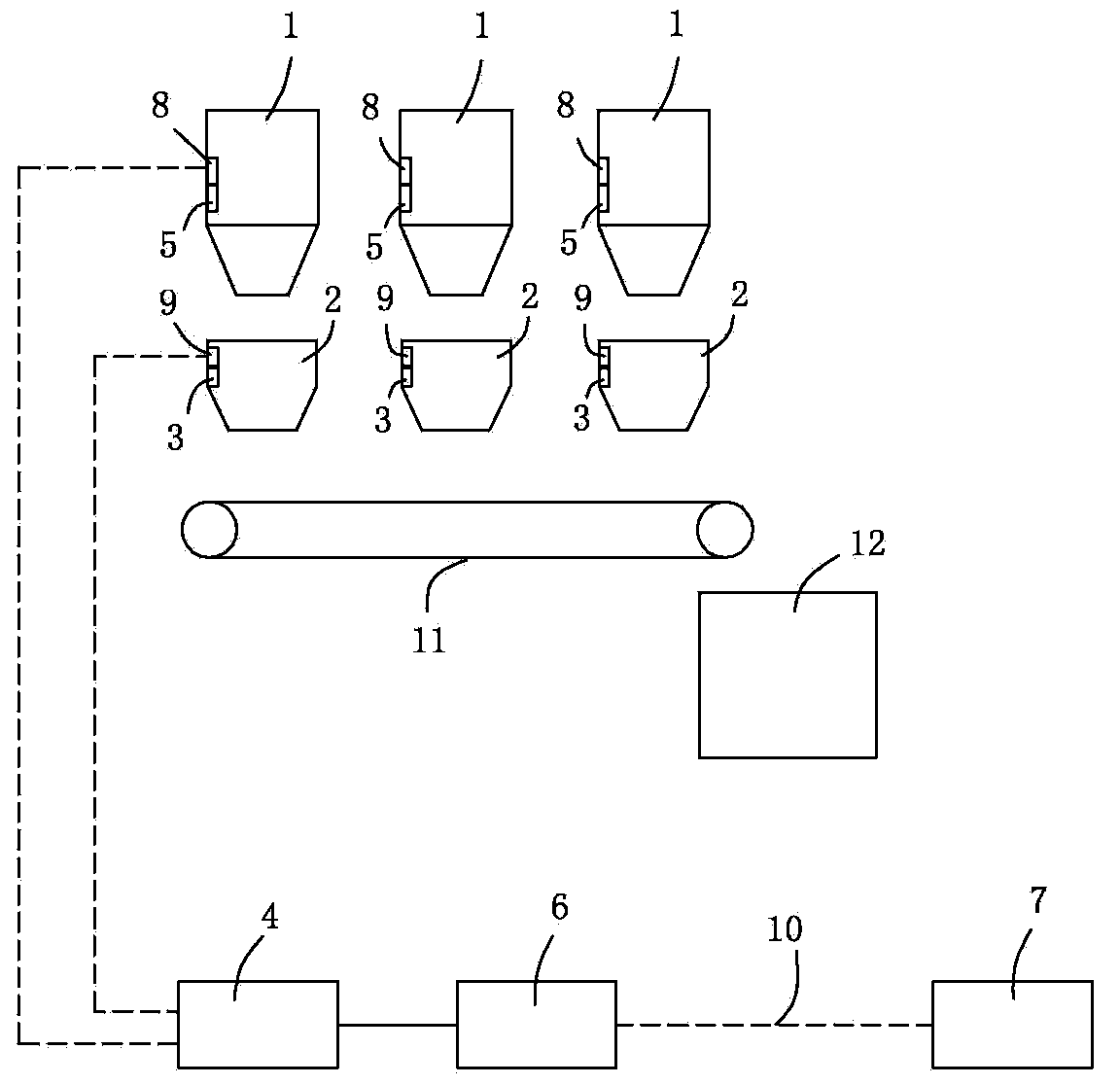

[0031] An example of an intermittent hot-mix asphalt mixture production gradation real-time monitoring system, see figure 1 The system includes a weight sensor 3 arranged in a batching scale 2 under a plurality of hot silos 1 of the mixing station, and the signal of the weight sensor is connected to an industrial control machine 4, wherein the hot silos are also provided The temperature sensor 5, the temperature sensor signal is connected to the industrial control machine, a computer 6 with a data acquisition and analysis system is connected to the industrial control machine, and the computer is connected to a master control room server 7 through the network 10 through a GPRS data link. The material in the batching scale falls onto the conveyor belt 11, and the conveyor belt sends the material to the mixer 12 for mixing.

[0032] The weight sensor signal and the temperature sensor signal can be connected to the industrial control machine through a laid cable respectively; however,...

Embodiment 2

[0034] An embodiment of a method for real-time monitoring of batch-type hot-mix asphalt mixture production gradation is based on the monitoring method of the batch-type hot-mix bituminous mixture production gradation real-time monitoring system described in Example 1. The method includes:

[0035] a. Formulate the gradation control range of the hot mix asphalt material for construction: determine the standard mix ratio for construction from three stages: target mix design, production mix design, and production mix verification. Different hot mix asphalt silos are used in different silos Vibrating screens with different sieve holes are set below the sieve, and the material quality control range of each bin in the production gradation is determined by the permissible fluctuation range of the quality of the material passed through each sieve;

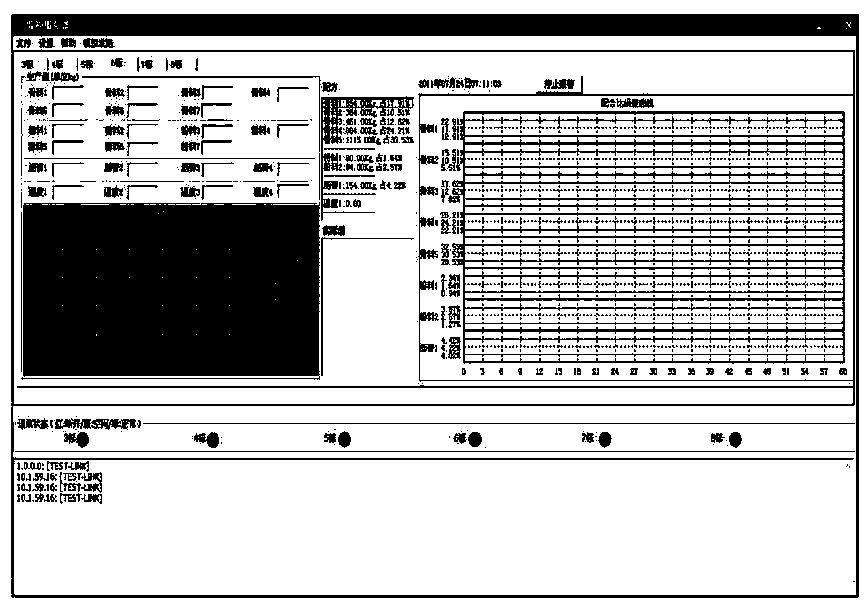

[0036] b. Display the quality control range of each warehouse material in the form of a graphic monitoring interface, the graphic is a curve gr...

Embodiment

[0046] Example: A certain project is the lower layer of an expressway asphalt pavement, the mixture type is AC-20, and the layer thickness is 7 cm. During the mixing process of the mixture, the construction unit uses the method provided by the present invention as a guide to realize the real-time monitoring of the production gradation of the hot-mix asphalt mixture, which is specifically carried out in the following steps:

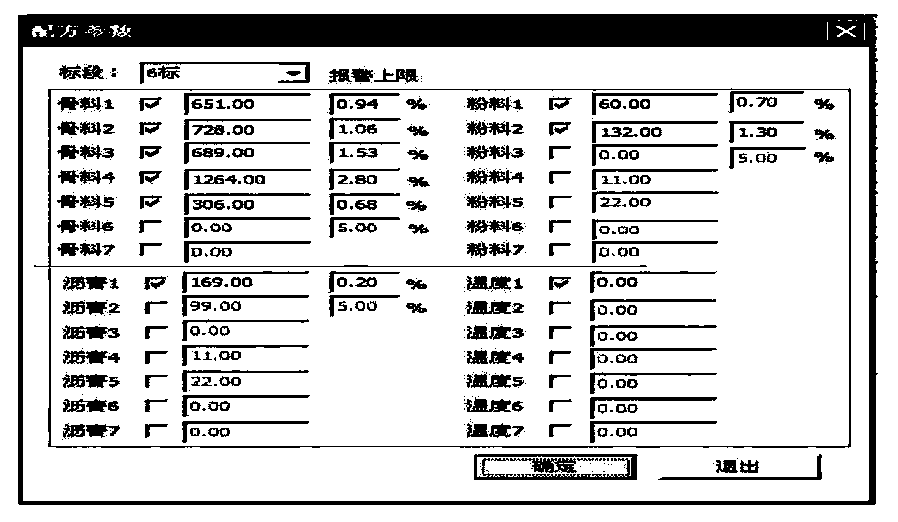

[0047] (1) Design of hot-mix asphalt mixture: adopts a three-stage design of target mix ratio, production mix ratio, and production mix ratio verification. After passing the verification, the standard mix ratio for construction and the allowable fluctuation range of the materials through each sieve are finally determined. Figure 4 .

[0048] (2) Through an industrial computer connected to the computer in the control room of the mixing plant, intercept the real-time production data on the computer in the control room of the mixing station, such as: number of tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com