Adhesive cement stirring device

A mixer and mortar technology, applied in the fields of mortar mixers and high-viscosity mortar mixing equipment, can solve the problems of long mixing time, low efficiency, and difficulty in cleaning the mixing drum, and achieve uniform and sufficient mixing, high efficiency, and shortened mixing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

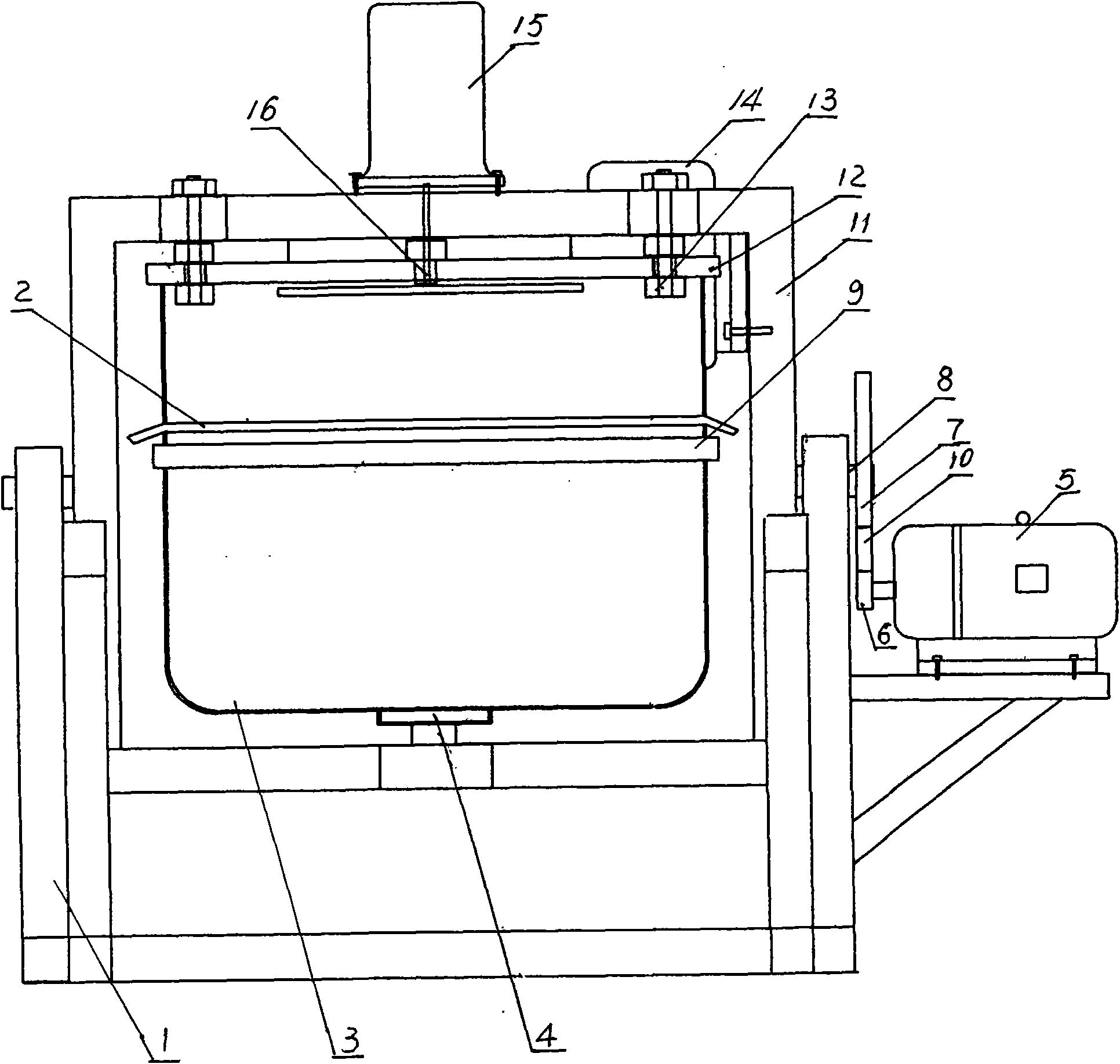

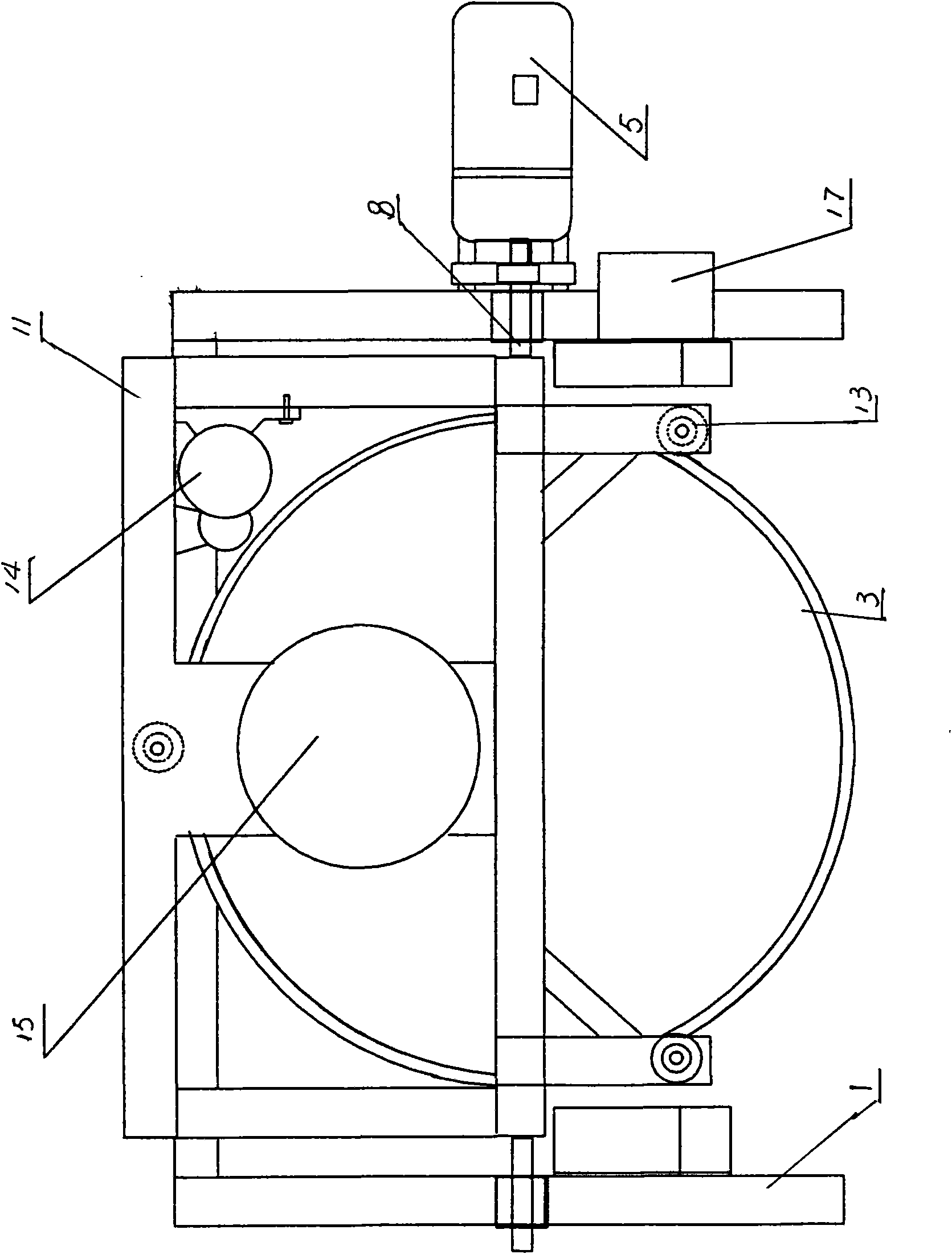

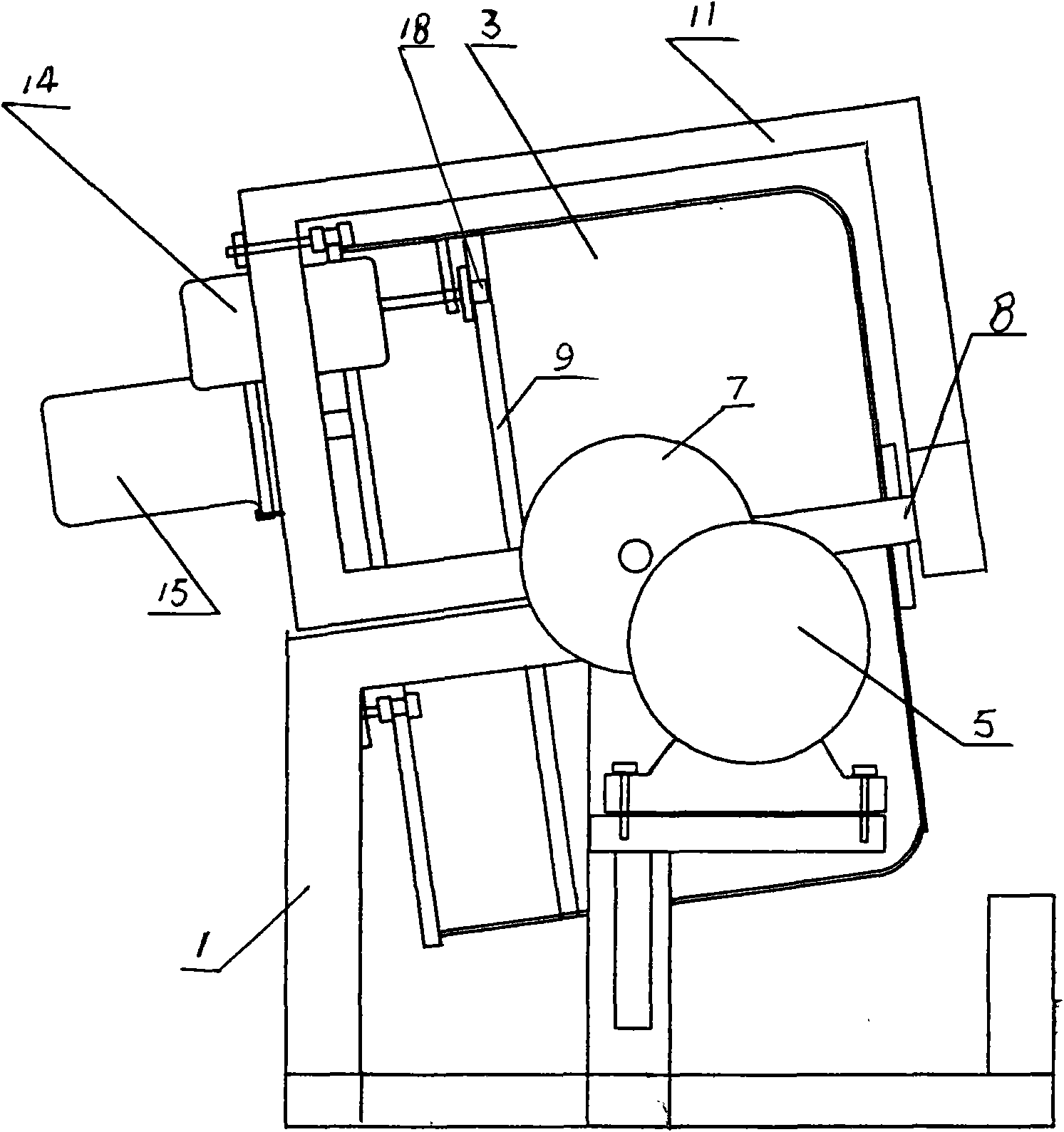

[0017] Refer to attached Figure 1~4 , The mortar mixer includes a frame 1, a cylinder 3, a cylinder positioning roller 13, a cylinder overturning bracket 11, a cylinder overturning discharge motor 5, a cylinder rotation deceleration motor 14, a stirring deceleration motor 15 and an agitator 16. The cylinder body 3 is installed on the cylinder body turning bracket 11 through the cylinder body support bearing seat 4, the cylinder body 3 is provided with a ring gear 9, and three positioning rollers 13 are installed on the upper part of the cylinder body turning bracket 11, and the three positioning rollers 13 are clamped The mouth 12 on the cylinder body is used for the positioning of the cylinder body 3, and can prevent the cylinder body 3 from slipping off from the cylinder body turning support 11 when the cylinder body 3 is turned over and unloaded. Both sides of the barrel turning bracket 11 are equipped with barrel turning shaft 8, the barrel turning shaft 8 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com