Sound wave mixing device based on three-freedom-degree resonance system

A mixing device and a technology with a degree of freedom, which is applied in the direction of shaking/oscillating/vibrating mixers, mixers, fluids using vibration, etc., can solve the problems that the feeding process cannot be added at the same time, affects the production efficiency of the enterprise, and the materials are difficult to clean, etc., to achieve High mixing efficiency, outstanding energy-saving effect, and the effect of narrowing the difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

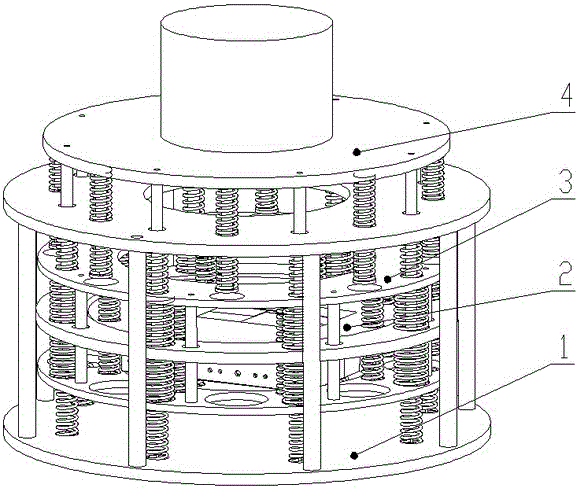

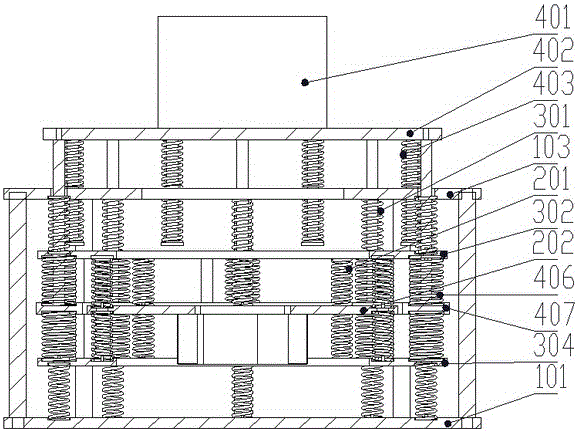

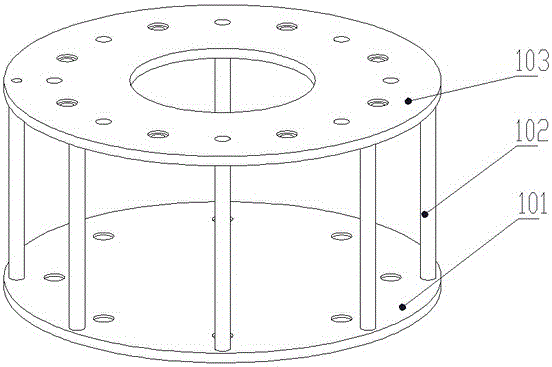

[0039] figure 1 Among them, the mixing device is composed of a frame 1, an excitation unit 2, a reaction unit 3 and a load unit 4. The reaction unit 3 is located in the middle of the frame 1, connected to the upper plate 103 and the lower plate 101 of the frame 1 through the second spring (301a / b); the excitation unit 2 is located in the middle of the reaction unit 3, and connected to the The upper plate 302 and the lower plate 304 of the reaction unit 3 are connected; the load unit 4 is located between the frame 1 and the reaction unit 3, and is connected to the frame 1 and the reaction unit through spring three (403a / b) and spring four (406a / b) respectively. Unit 3 is connected. The mixing container 401 can be fixed on the load unit 4 or on the reaction unit 3 , or two mixing containers 401 can be fixed on the load unit 4 and the reaction unit 3 at the same time. The vibrating device of the vibrating unit 2 can be an eccentric mechanical vibrator, or an electromagnetic vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com