Double-shaft swing type high-thickness material stirrer

A swinging, high-viscosity technology, applied in the field of mixing machinery, can solve the problems of inability to crush material blocks and insufficient mixing and mixing, and achieve the effects of improving mixing efficiency, improving mixing efficiency, improving mixing efficiency and mixing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below will combine specific embodiment and Attached picture , clearly and completely describe the technical solutions in the embodiments of the present invention, obviously, the described embodiments are only some preferred embodiments of the present invention, not all the embodiments. Those skilled in the art can make similar modifications without departing from the connotation of the present invention, so the present invention is not limited by the specific embodiments disclosed below.

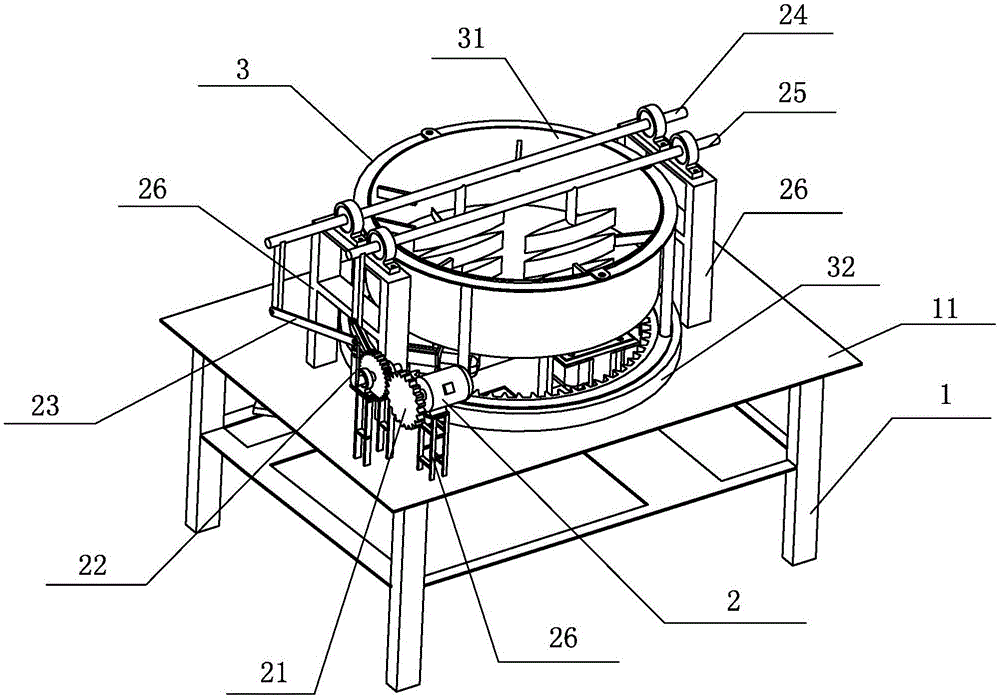

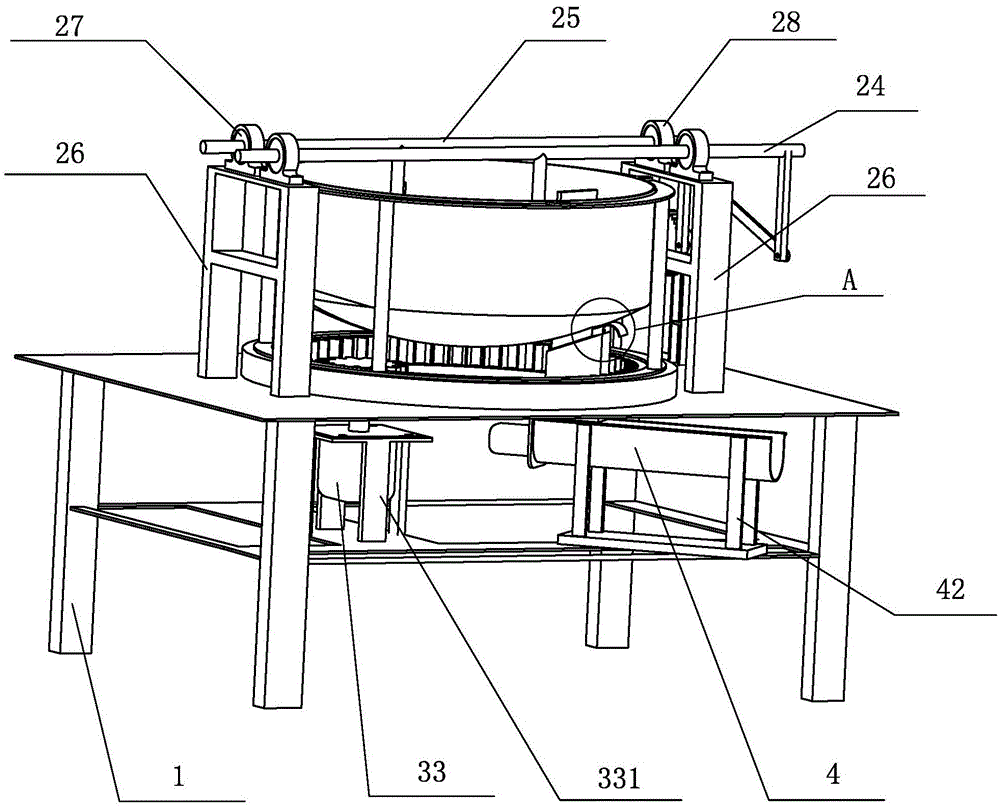

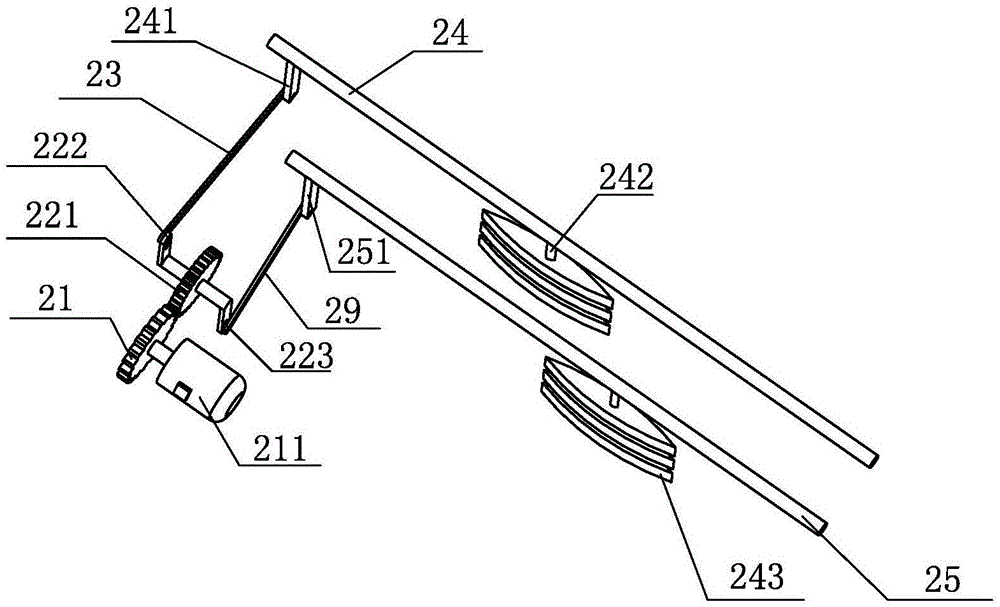

[0041]The present invention provides a double-shaft swing mixer, which comprises a mixing bucket 31, a whole machine support 1, a swing mechanism 2, a rotating mechanism 3 and a feeding mechanism 4, and the mixing bucket 31 is arranged on the whole machine support 1 .

[0042] The whole machine support 1 includes four legs and a whole machine support flat plate 11 arranged on the four legs, a large round hole is opened in the center of the whole machine support flat plate 11, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com