Mixed-material discharging apparatus capable of realizing uniform mixing of materials

A technology of uniform mixing and discharging device, applied in mixers, mixers with rotary stirring devices, dissolving and other directions, can solve the problems affecting mixing quality and uneven mixing, etc., to improve mixing quality, reduce friction, reduce effect of load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

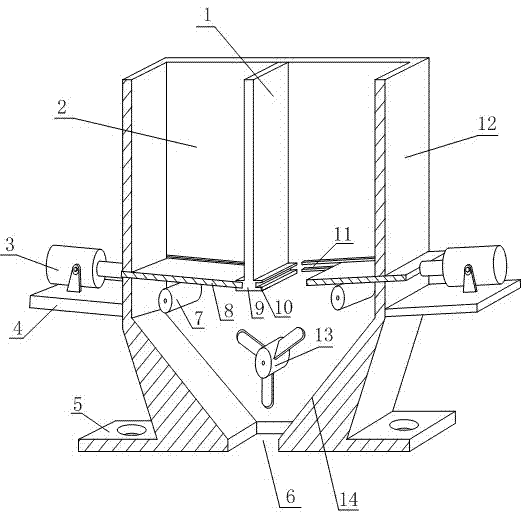

[0014] Such as figure 1 Shown: a uniform mixing and discharging device, including a metal shell 12, the metal shell 12 is provided with a discharge cavity 2, and the middle part of the discharge cavity 2 is vertically provided with a partition separating the discharge cavity 2 The partition 1, the metal shell 12 is located in the discharge cavity 2, and the left and right sides of the lower end of the partition 1 are respectively inclined to be provided with baffles 8, and the two baffles 8 pass through the left and right sides respectively. The metal shells 12 on the right sides are connected with hydraulic cylinders 3, and the hydraulic cylinders 3 can drive the baffles 8 to move. The hydraulic cylinders 3 are fixed by the fixing plates 4 at the outer ends of the metal shells 12. The lower end of the lower end is also provided with a driven roller 7 which is in contact with the baffle plate 8. The metal shell 12 is provided with a material leakage port 6 in the middle of the...

Embodiment 2

[0020] In this embodiment, the following structure is added on the basis of Embodiment 1, specifically: a guide chute 11 is provided inside the metal shell 12 , and the side ends of the two baffles 8 are located inside the guide chute 11 .

[0021] The guide chute 11 of this embodiment is used to limit and guide the baffle 8 to move in a certain direction, which not only plays a supporting role for the baffle 8, reduces the vibration that occurs when it moves, but also ensures the movement of the baffle 8 The direction reduces the friction between it and the metal shell 12, reduces the friction noise, and also makes the baffle 8 move more smoothly.

Embodiment 3

[0023] This embodiment is further limited on the basis of embodiment 1 or embodiment 2, specifically: the range of inclination angle of the aggregate slope 14 is 70°-90°.

[0024] In order to make the collection slope 14 have a good guiding and buffering effect in this embodiment, its inclination angle is limited between 70°-90°, so that the collection slope 14 can not only guide the raw materials to leak from the leakage port 6, but also prevent The accumulation of raw materials on the aggregate slope 14 affects the discharge, and at the same time, the raw materials can slowly fall to the leakage port 6 on the collection slope 14 with the action of gravity, so as to prevent the raw materials from blocking the leakage port 6 at one time, and play a good role. buffering effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com