Fracturing base liquid mixer

A technology of fracturing base fluid and mixer, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of incomplete swirl flow, slow flow rate, and high requirements for gas inflow, so as to reduce resources The waste, the realization of energy efficiency ratio, the effect of the best energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

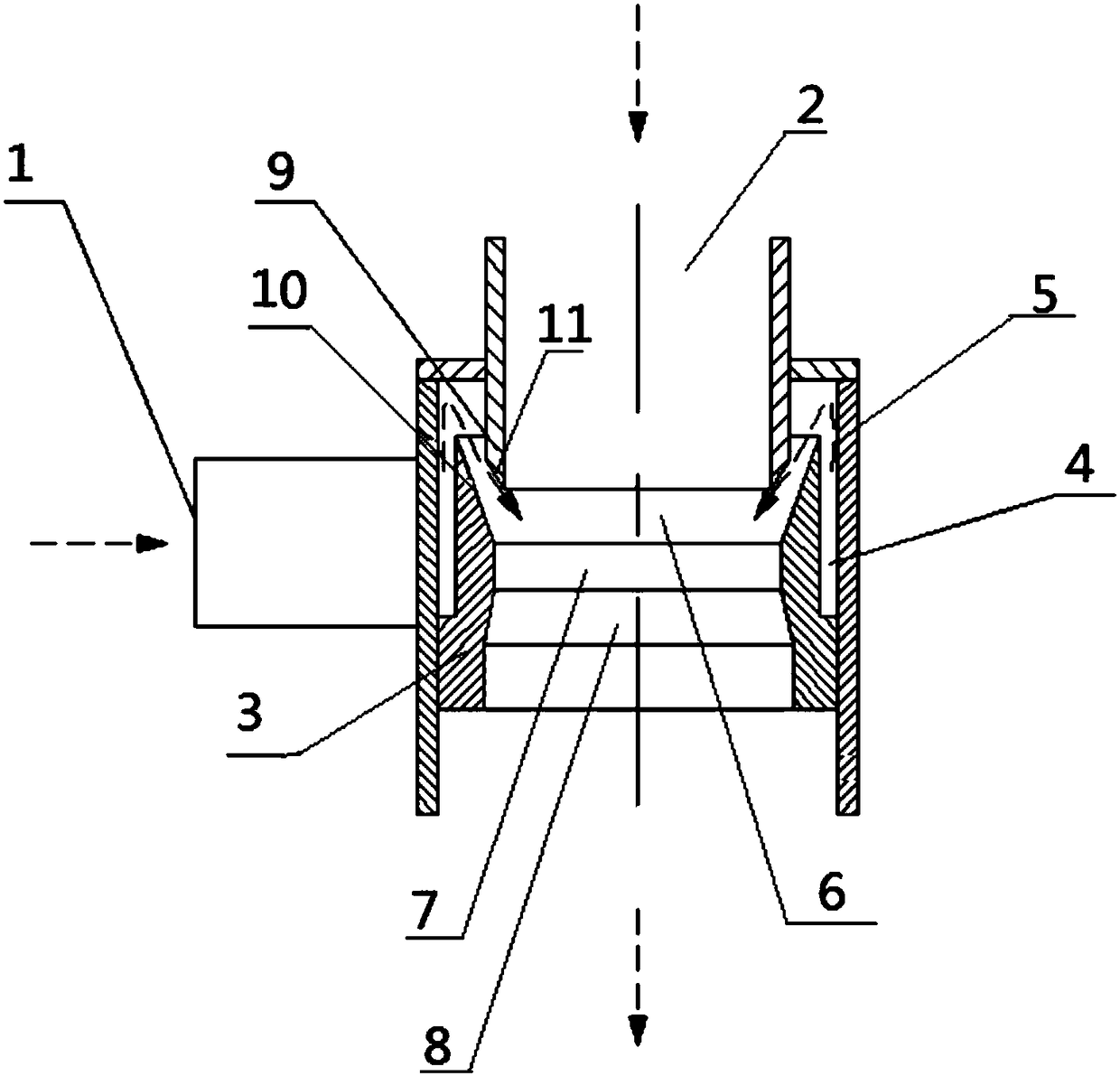

[0023] Such as figure 1 Shown: a fracturing base fluid mixer, including a swirl premixing device, the swirl premixing device includes a liquid inlet 1, a feed port 2, a connecting piece 3 and an annulus 4, and the feed port 2 Set vertically, the liquid inlet 1 is arranged horizontally, the side wall 9 of the feed port 2 is connected with the sleeve 5, the connecting piece 3 is arranged inside the sleeve 5, and the connecting piece 3 and the side wall 9 of the feed port 2 form an annular space 4. The annulus 4 communicates with the liquid inlet 1. The lower end of the side wall 9 of the feed inlet 2 has a hypotenuse 11, and the upper part of the connector 3 has a slope 10. Both the slope 10 and the slope 11 have a certain angle with the vertical plane. , the angle is 10 to 80 degrees, as long as the angle between the inclined plane 10 and the hypotenuse 11 and the vertical plane is within 10 to 80 degrees, preferably the inclined plane 10 and the hypotenuse 11 are arranged in p...

Embodiment 2

[0027] Embodiment 1 is connected in series with a high-pressure jet mixer, and the high-pressure jet mixer is either a constant flow type or a variable flow type.

Embodiment 3

[0029] Example 1 was connected in series with a shear type mixer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com