A control method of chiller with evaporative condenser

An evaporative condenser and control method technology, which is applied in the field of air conditioning, can solve the problems of not saving energy, and achieve the effect of improving energy efficiency ratio and high energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

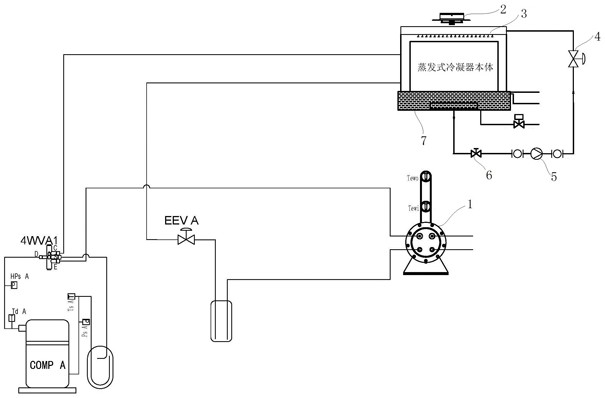

Image

Examples

Embodiment 2

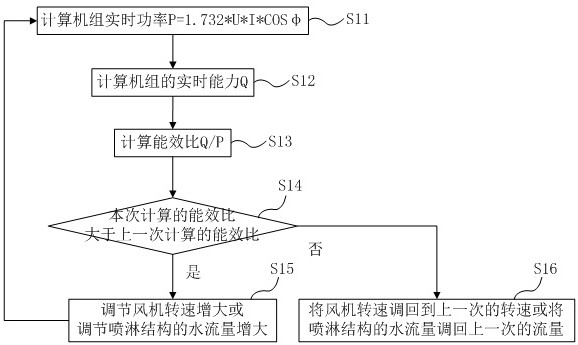

[0074] Embodiment 2. The difference between this embodiment and Embodiment 1 is: first adjust the fan speed, and then adjust the water flow of the spraying structure when the energy efficiency ratio no longer increases. The chiller control method with evaporative condenser in this embodiment specifically includes the following steps, see image 3 shown.

[0075] Step S21: The real-time power of the computer group P=1.732*U*I*COSφ.

[0076] Step S22: The real-time capability of the computer group Q=C*V*|T WI -T WO |.

[0077] Step S23: Calculate the energy efficiency ratio Q / P.

[0078] Steps S21-S23 are the same as those described in Embodiment 1, and reference may be made to Embodiment 1, and details will not be repeated here.

[0079] Step S24: Determine whether the energy efficiency ratio calculated this time is greater than the energy efficiency ratio calculated last time.

[0080] If yes, execute step S25.

[0081] If not, execute step S26.

[0082] Step S25: Adju...

Embodiment 3

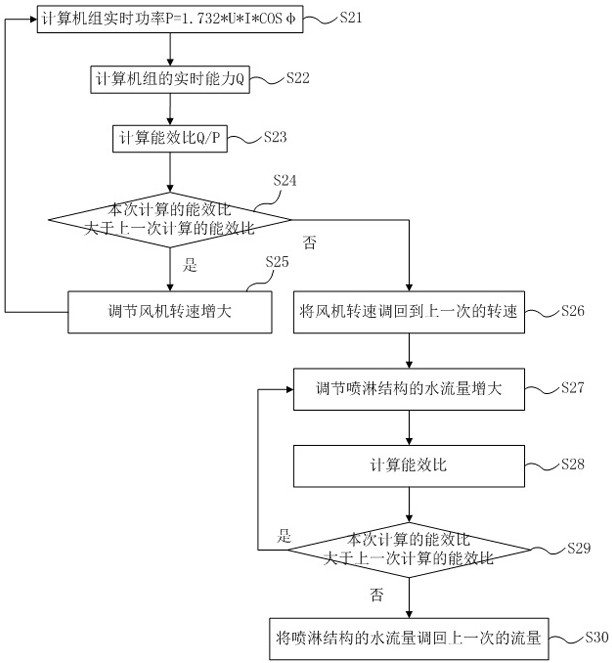

[0104] Embodiment 3. The difference between this embodiment and Embodiment 1 is that: first adjust the water flow rate of the spray structure, and then adjust the fan speed when the energy efficiency ratio no longer increases. The chiller control method with evaporative condenser in this embodiment specifically includes the following steps, see Figure 4 shown.

[0105] Step S31: The real-time power of the computer group P=1.732*U*I*COSφ.

[0106] Step S32: Real-time capability Q=C*V*|T of the computer group WI -T WO |.

[0107] Step S33: Calculate the energy efficiency ratio Q / P.

[0108] Steps S31-S33 are the same as the descriptions of the first embodiment, and reference may be made to the first embodiment, and details are not repeated here.

[0109] Step S34: Determine whether the energy efficiency ratio calculated this time is greater than the energy efficiency ratio calculated last time.

[0110] If yes, execute step S35.

[0111] If not, execute step S36.

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com