Precise defrosting intelligent control method and system for air-conditioning refrigerator

An intelligent control and air-conditioning technology, applied in defrosting, refrigerators, refrigeration components, etc., can solve the problems of unpopularity, increased energy consumption, late defrosting operation, etc., achieve high defrosting control accuracy and reduce air-conditioning refrigerators , to avoid the effect of misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

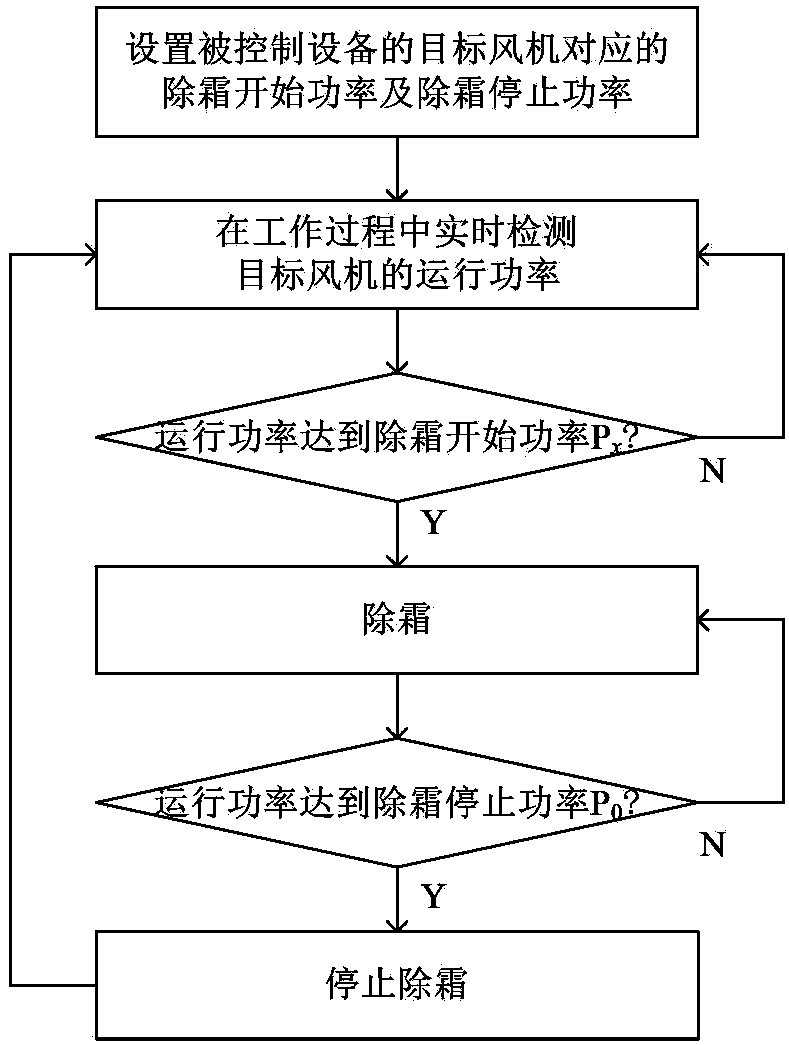

[0051] Such as figure 1 As shown, the implementation steps of the intelligent control method for precise defrosting of air-conditioned refrigerators in this embodiment include:

[0052] 1) Set the defrosting start power P corresponding to the target fan of the controlled device x and defrosting stop power P 0 , the controlled device is an air conditioner or refrigerator, and the target fan is the outdoor unit fan of the air conditioner or the evaporator fan of the refrigerator;

[0053] 2) Detect the operating power of the target fan in real time during the working process, when the operating power of the target fan reaches the defrosting start power P x , the fins of the controlled equipment start to defrost, and when the operating power of the target fan reaches the defrosting stop power P 0 stop defrosting the fins of the controlled equipment.

[0054] In this embodiment, the defrosting stop power P in step 1) 0 Specifically, it refers to the power of the target fan of...

Embodiment 2

[0068] This embodiment is basically the same as Embodiment 1, the main difference is: this embodiment is essentially an energy efficiency ratio follow-up defrosting method that controls the start and end time of defrosting based on the energy efficiency ratio, and the setting of step 1) is controlled When the defrosting start power corresponding to the target fan of the device is used, the method of determining the defrosting start power is different.

[0069] In this embodiment, when step 1) sets the defrosting start power corresponding to the target fan of the controlled device, the step of determining the defrosting start power includes:

[0070] 1.1B) Determine the power P of the target fan when the controlled equipment cannot work normally due to fin frosting through experiments in advance 1 , the power P of the target fan under the condition of no frost 2 ;

[0071] 1.2b) Apply power P 1 , power P 2 The power interval between is used as the optimization interval, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com