A dry-wet composite energy-saving floor and its heating method

A composite type, floor technology, applied in the field of floor heating, can solve the problems of slow heating speed, low heating efficiency, structural optimization, etc., and achieve the effect of fast heating speed, saving a lot of energy and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

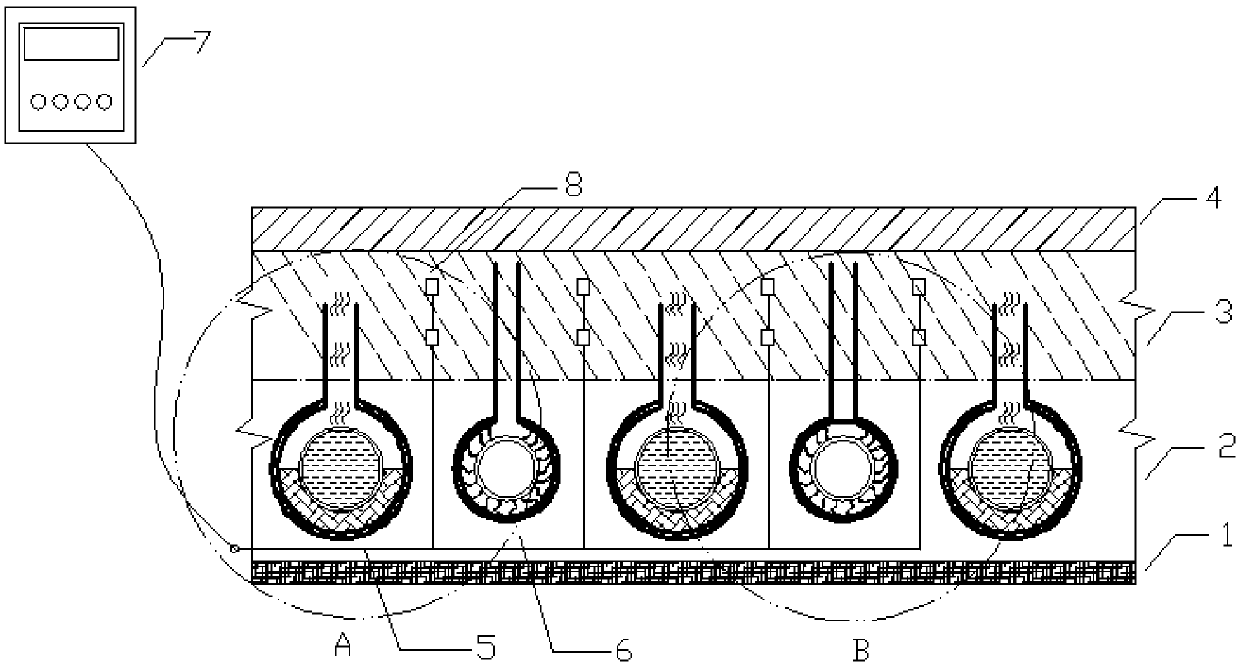

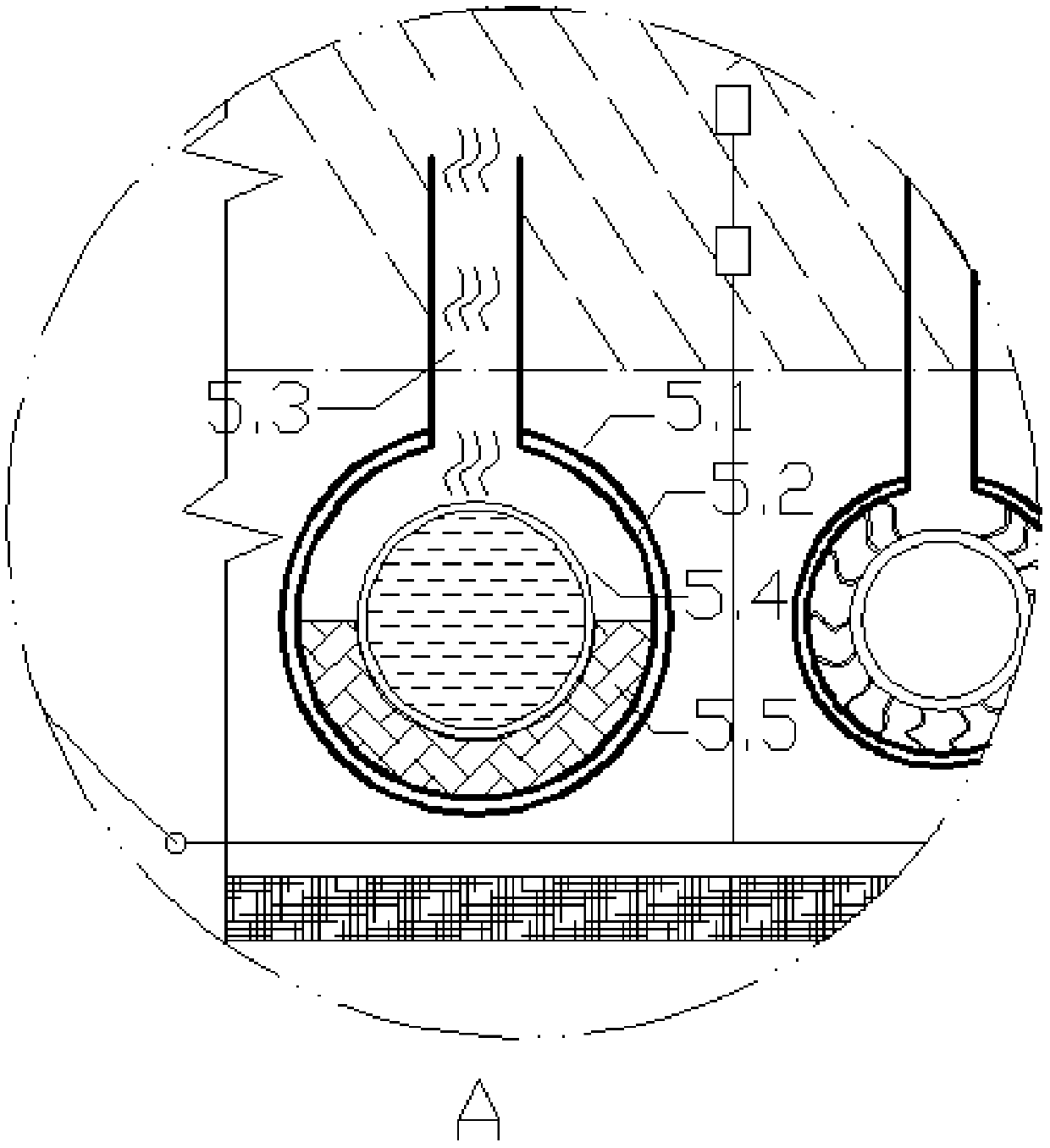

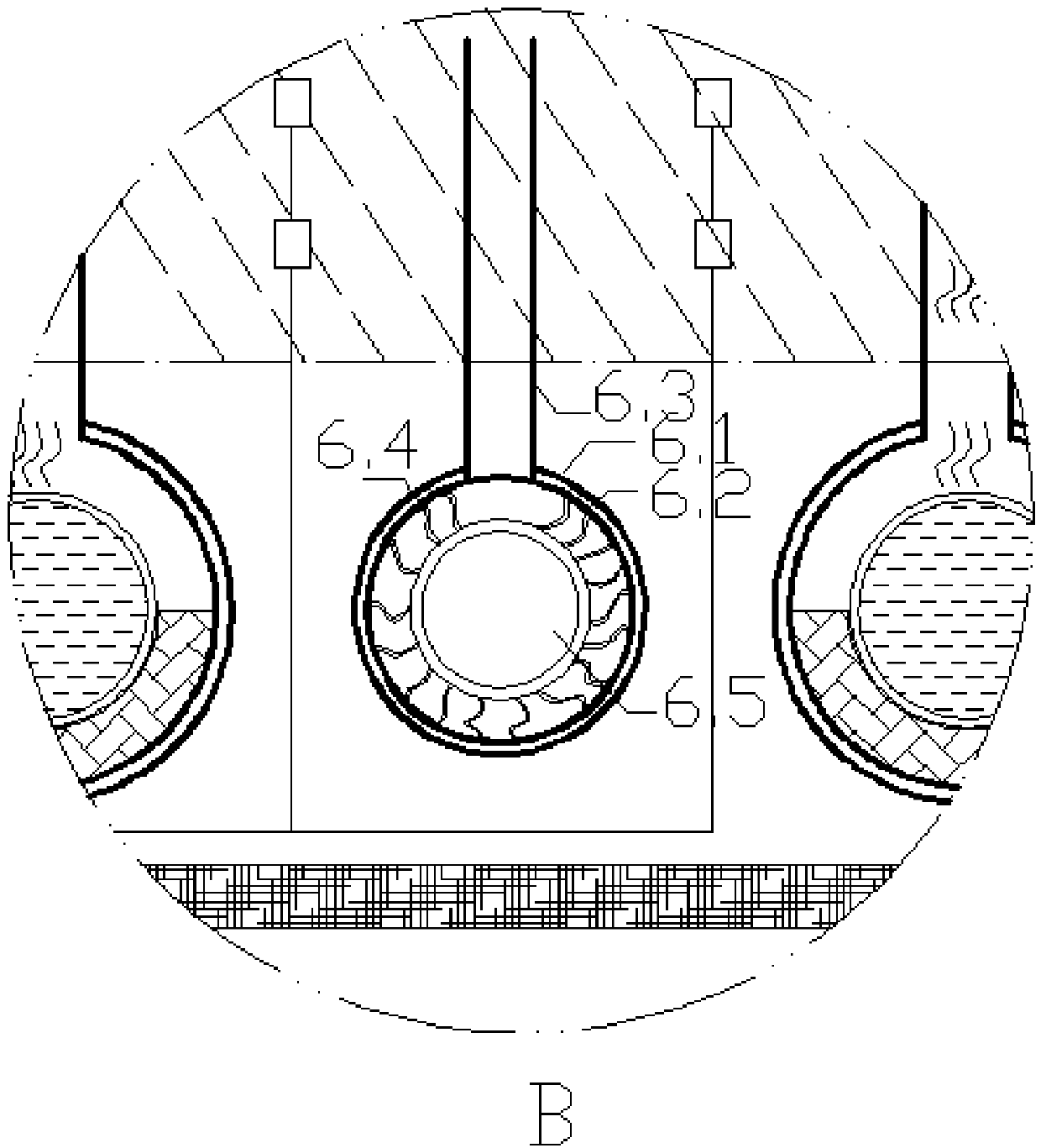

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The floor that is used for floor heating in the prior art is usually a multi-layer structure, see the attached figure 1 , the dry-wet composite energy-saving floor proposed by the present invention has a four-layer structure, and the four-layer structure is the most reasonable number of layers determined after a long period of production practice. 2. The heat transfer layer 3 and the decoration layer 4 . The heat insulation layer 1 is the bottom layer. On the one hand, it is used as the installation surface, that is, the outer surface of the heat insulation layer 1 is used to install the floor on the cement leveling layer or keel frame. On the other hand, the heat insulation layer 1 can effectively install the water heating components. 5 is insulated from the heat emitted by the electric heating assembly 6, so as to avoid heat loss outward. In the prior art, it is usua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com