Preparation method of light metal alloy semi-solid slurry

A semi-solid slurry and light metal technology, which is applied in the field of semi-solid alloy preparation, can solve the problems of unsatisfactory slurry structure, inconvenient operation in the preparation process, and low product quality, so as to save energy consumption and improve mixing efficiency and quality , high mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

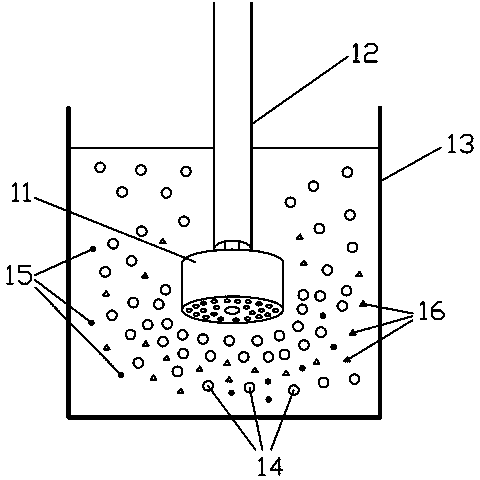

[0033] The technical solution adopted by the present invention is a method for preparing light metal alloy semi-solid slurry, the steps are:

[0034] (1) Prefabricate metal solution Ⅰ, melt 1 kg of Al-10%Si alloy ingot with a resistance furnace, pour metal solution Ⅰ, that is, Al-10%Si alloy, into the rod head and cool it for later use; the metal solution in each copper rod head ⅠThe weight is 0.03 kg;

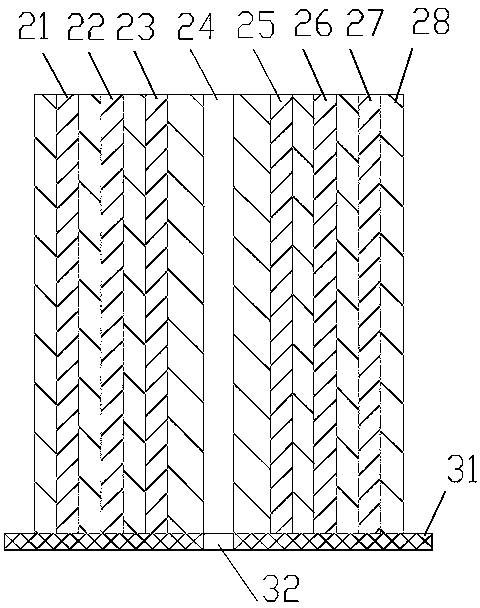

[0035] The stick head is in the shape of a cylinder, and the central axis of the stick head is provided with a vertical air flow hole; the stick head outside the circumference of the air flow hole is provided with a plurality of solidification through holes parallel to the air flow hole; the upper end of the air flow hole and the stirring The lower end of the rod is sealed and connected; the bottom surface of the rod head is detachably provided with a circular baffle to prevent the metal solution I from flowing out of the solidified through hole, and the center of the circular...

Embodiment 2

[0040] A method for preparing a light metal alloy semi-solid slurry, the steps of which are:

[0041] (1) Prefabrication of metal solution I, melting 1 kg of A356 aluminum ingot with a resistance furnace, pouring metal solution I, that is, A356 aluminum, into the rod head for cooling; the weight of metal solution I in each rod head is 0.05 kg;

[0042] The stick head is cylindrical, and the central axis of the stick head is provided with a vertical air flow hole; the stick head outside the circumference of the air flow hole is provided with a plurality of solidification through holes parallel to the air flow hole; the upper end of the air flow hole and the stirring The lower end of the rod is sealed and connected; the bottom surface of the rod head is detachably provided with a circular baffle to prevent the metal solution I from flowing out of the solidified through hole, and the center of the circular baffle is provided with an air hole that matches the lower end of the air f...

Embodiment 3

[0047] A method for preparing a light metal alloy semi-solid slurry, the steps of which are:

[0048] (1) Prefabrication of metal solution I, melting 1 kg of AZ91 magnesium ingot with a resistance furnace, pouring metal solution I, namely AZ91 magnesium, into the rod head for cooling; the weight of metal solution I in each rod head is 0.04 kg;

[0049] The stick head is in the shape of a cylinder, and the central axis of the stick head is provided with a vertical air flow hole; the stick head outside the circumference of the air flow hole is provided with a plurality of solidification through holes parallel to the air flow hole; the upper end of the air flow hole and the stirring The lower end of the rod is sealed and connected; the bottom surface of the rod head is detachably provided with a circular baffle to prevent the metal solution I from flowing out of the solidified through hole, and the center of the circular baffle is provided with an air hole that matches the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com