Paddle type mixing machine

A mixer and paddle technology, applied in mixers, mixers with rotary stirring devices, dissolution and other directions, can solve the problem of affecting the mixing speed and mixing accuracy of the mixer, the effect of convection mixing and shear mixing is small, and there is no obvious effect. Improve and other issues, to achieve the effect of good promotion and application value, low cost, novel and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

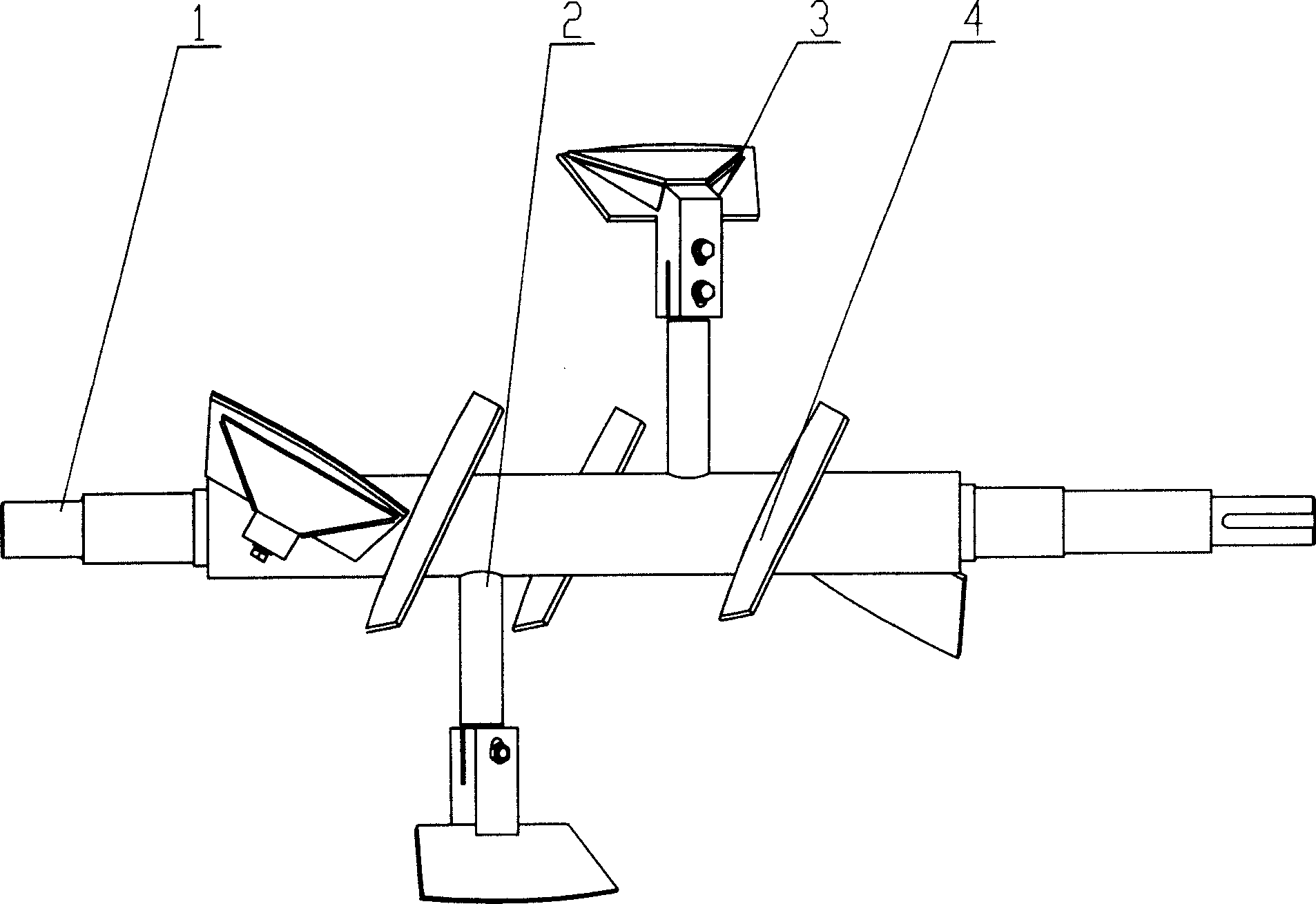

[0015] Embodiment 1: A mixing drum is installed on the machine body, a rotating shaft 1 is installed in the mixing drum, a strut 2 is installed on the rotating shaft 1 , and a paddle 3 is installed on the strut 2 . The auxiliary blade 4 is welded on the rotating shaft between the two struts 2 on the rotating shaft, and the axial distance between the auxiliary blade 4 and the two struts 2 is equal.

Embodiment 2

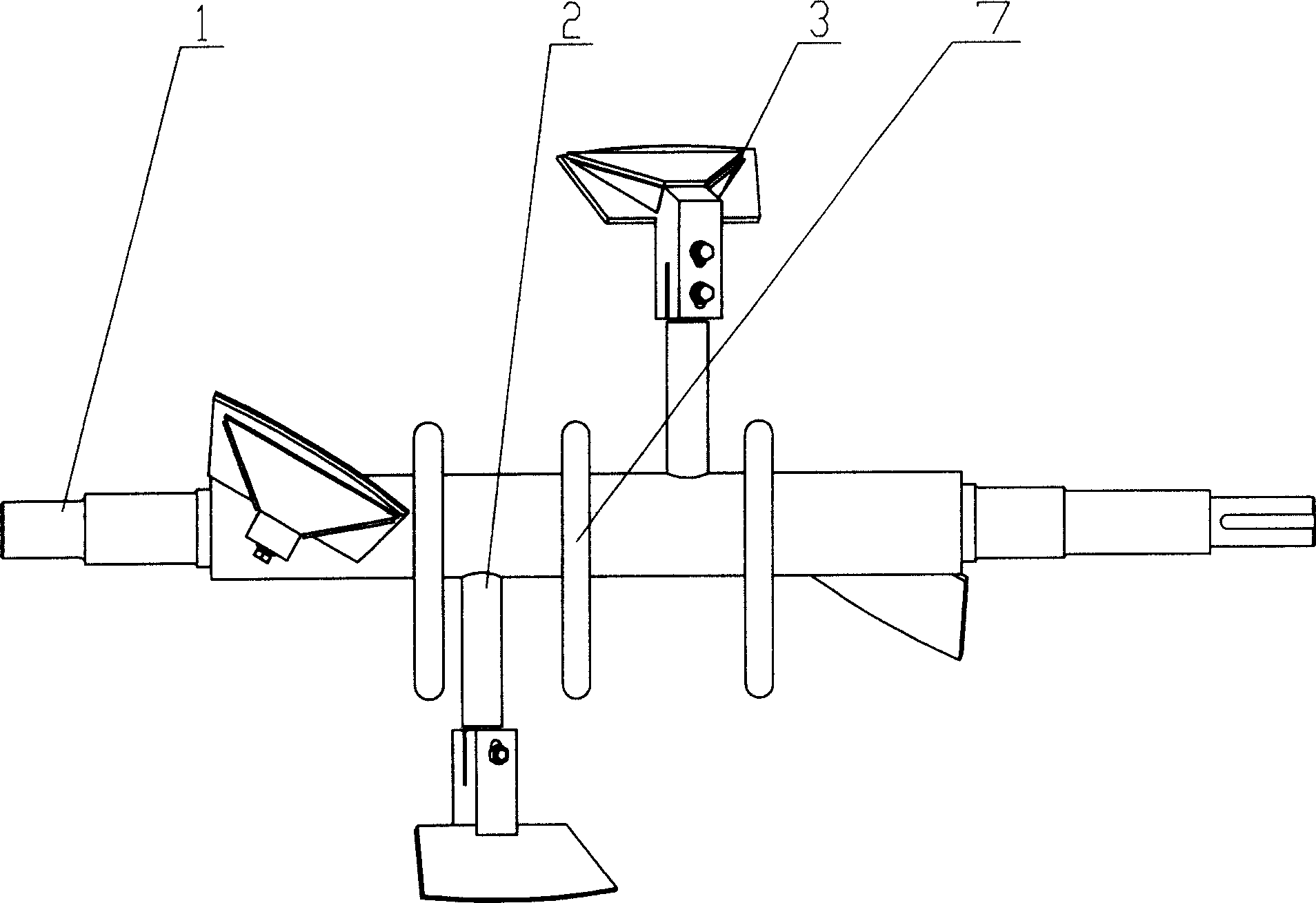

[0016] Embodiment 2: Install a mixing drum on the body, install a rotating shaft 1 in the mixing drum, install a strut 2 on the rotating shaft 1, and install a paddle 3 at the end of the strut. The stirring ring 7 is welded on the rotating shaft between the two struts 2 on the rotating shaft, and the axial distance between the stirring ring 7 and the two struts 2 is equal.

Embodiment 3

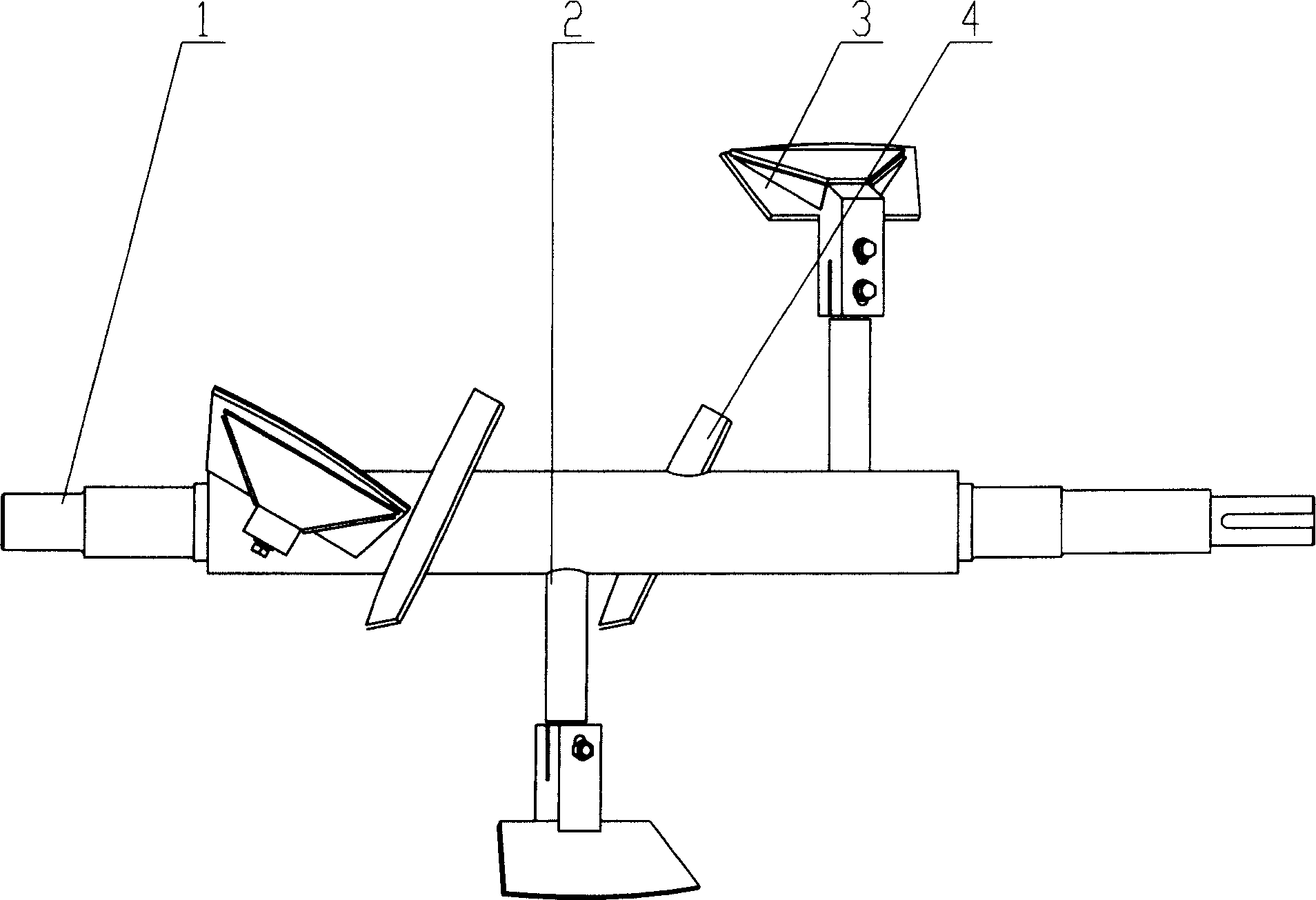

[0017] Embodiment 3: A mixing drum is installed on the machine body, a rotating shaft 1 is installed in the mixing drum, a strut 2 is installed on the rotating shaft 1, and paddles 3 are installed at the ends of the strut 2 . The auxiliary paddle 4 is installed by bolts in the middle section of the strut 2, and the direction of the auxiliary blade 4 can be adjusted by installing the bolts. The installation direction of the auxiliary blade is at a certain angle or opposite to that of the blade at the same pole end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com