Fuel cell metal bipolar plate and manufacturing method thereof

A metal bipolar plate and fuel cell technology, applied in the direction of fuel cells, fuel cell parts, final product manufacturing, etc., can solve the problem of affecting the uniformity of compression of the gas diffusion layer, difficulty in achieving continuity and automation, and bipolar The airtightness of the board can not be qualified, etc., to achieve the effect of easy assembly of the stack, easy realization of serialization and automation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

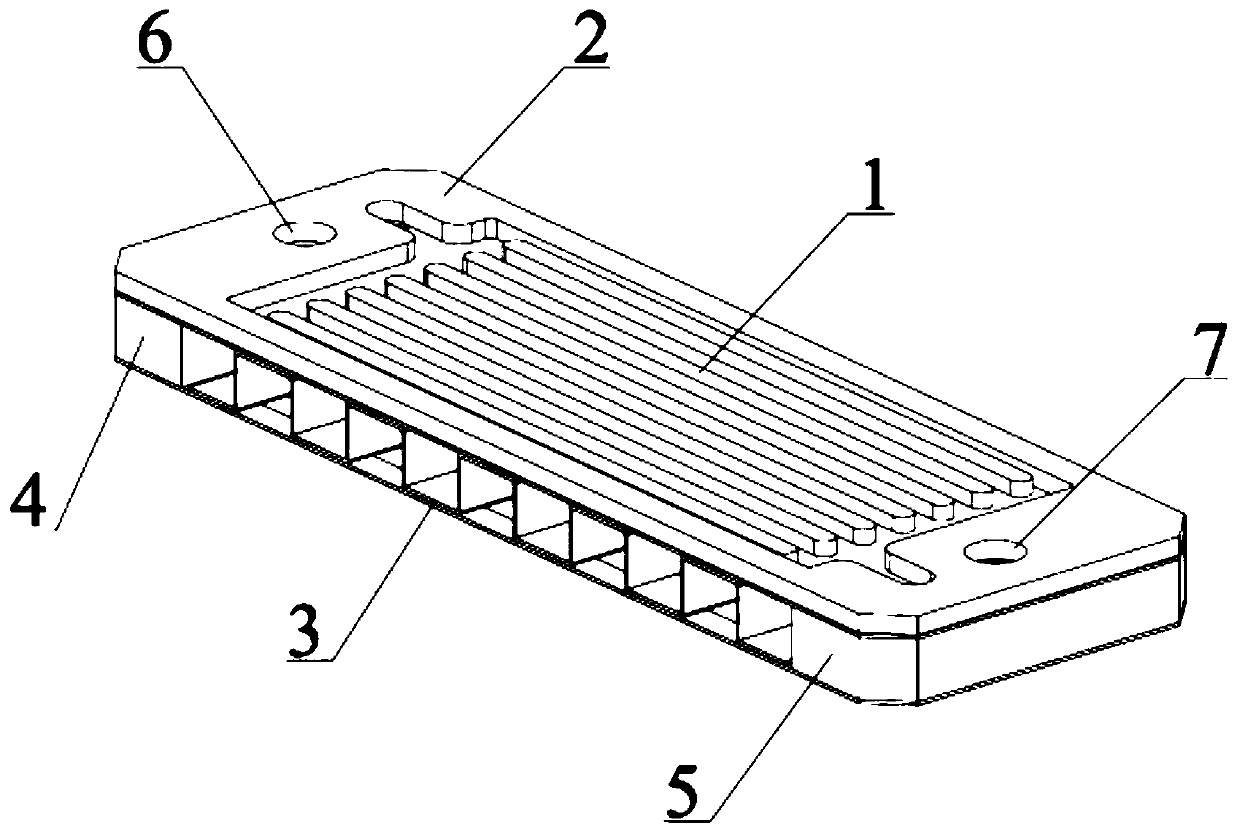

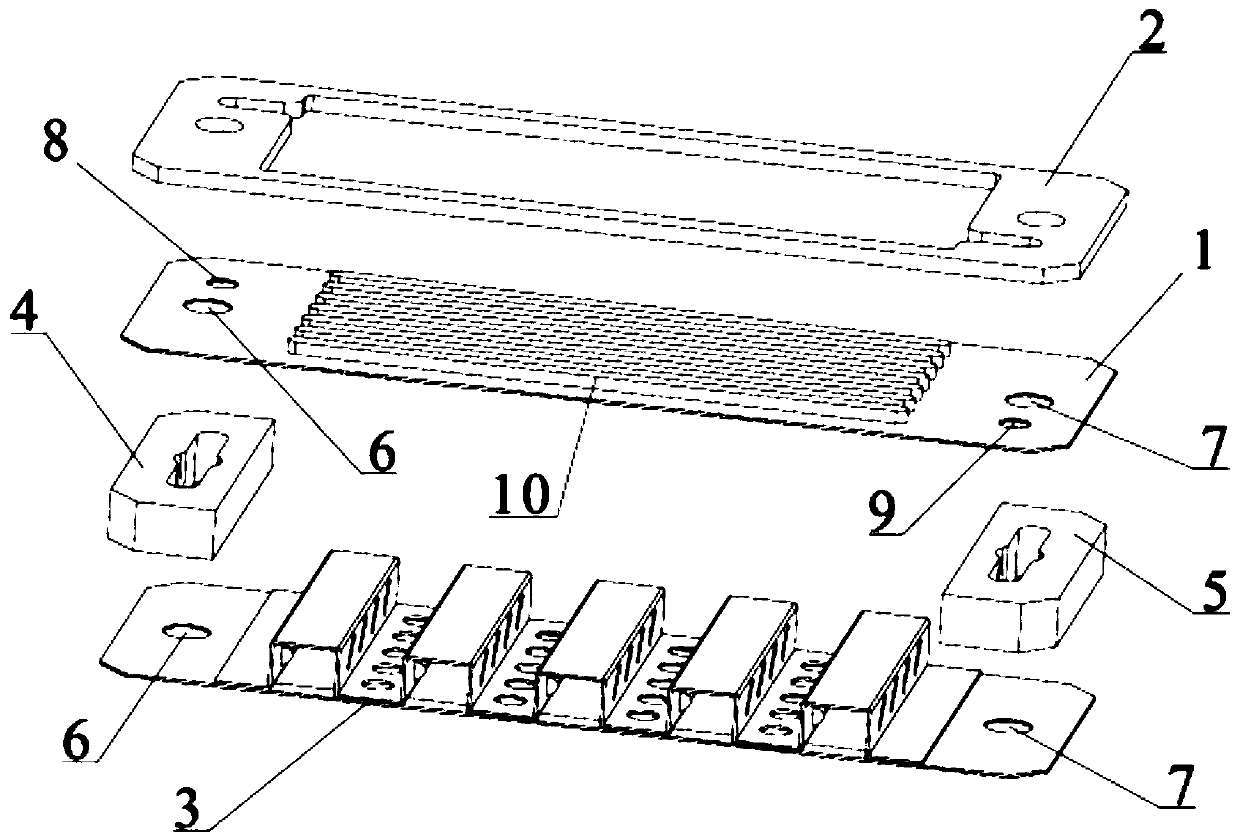

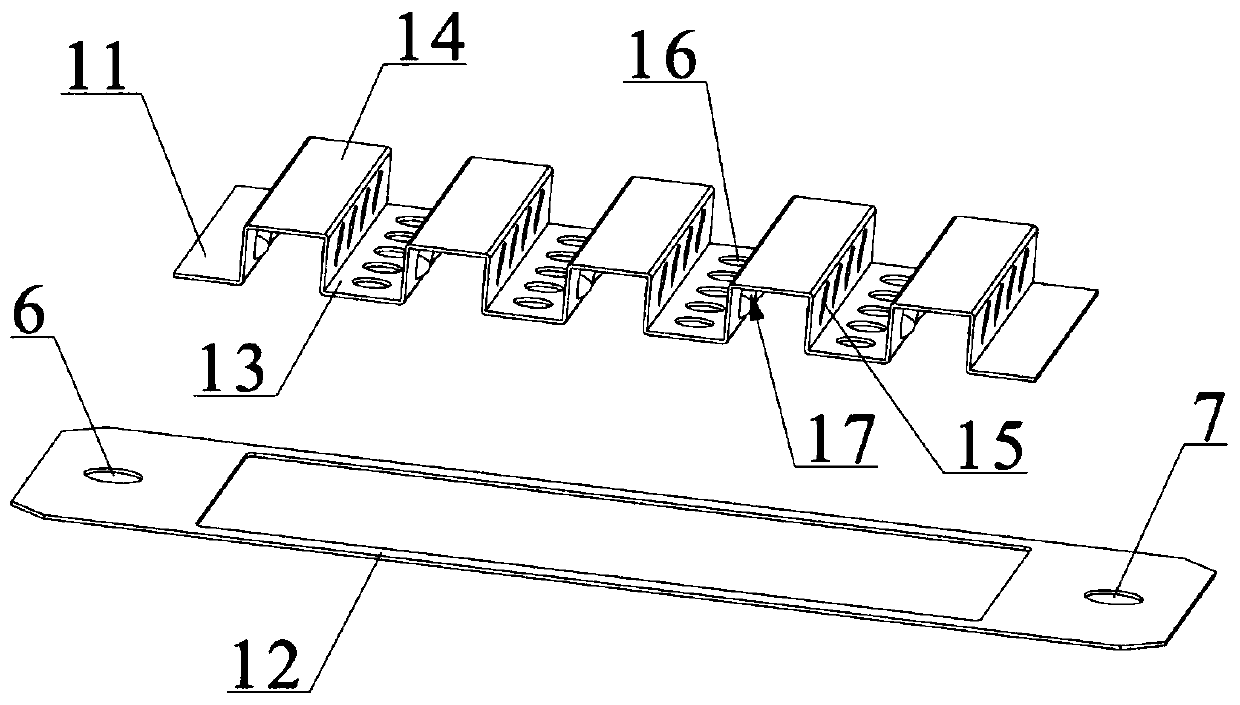

[0068] In the structure of the bipolar plate provided by the present invention, circular holes are distributed on the ridge of the cathode flow field, which is conducive to the transmission of reaction gas and generated water under the ridge, and is also conducive to the distribution of reaction heat at the ridge, which helps to increase the current density and The uniformity of its distribution improves the performance and life of the fuel cell at the same time; oblique grids are evenly distributed on both sides of the cathode flow field groove, on the one hand, part of the unreacted gas passing through the flow field ridge is forced to flow into the cathode flow field groove and flow into the cathode flow field. This part of the gas in the field slot acts as a gas block for the reaction gas originally flowing through the cathode flow field slot, that is, the back pressure effect, which is beneficial to increase the current density of the fuel cell. On the other hand, this part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ridge width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com