Arc-top piston top, arc-top piston and combustion chamber

A piston and arc top technology, applied in the direction of piston, engine lubrication, machine/engine, etc., can solve the problems of poor engine fuel economy, intake tumble loss, poor surface roughness, etc., and achieve the optimization and improvement of airflow movement form. The effect of knock dip, enhanced fuel flow and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

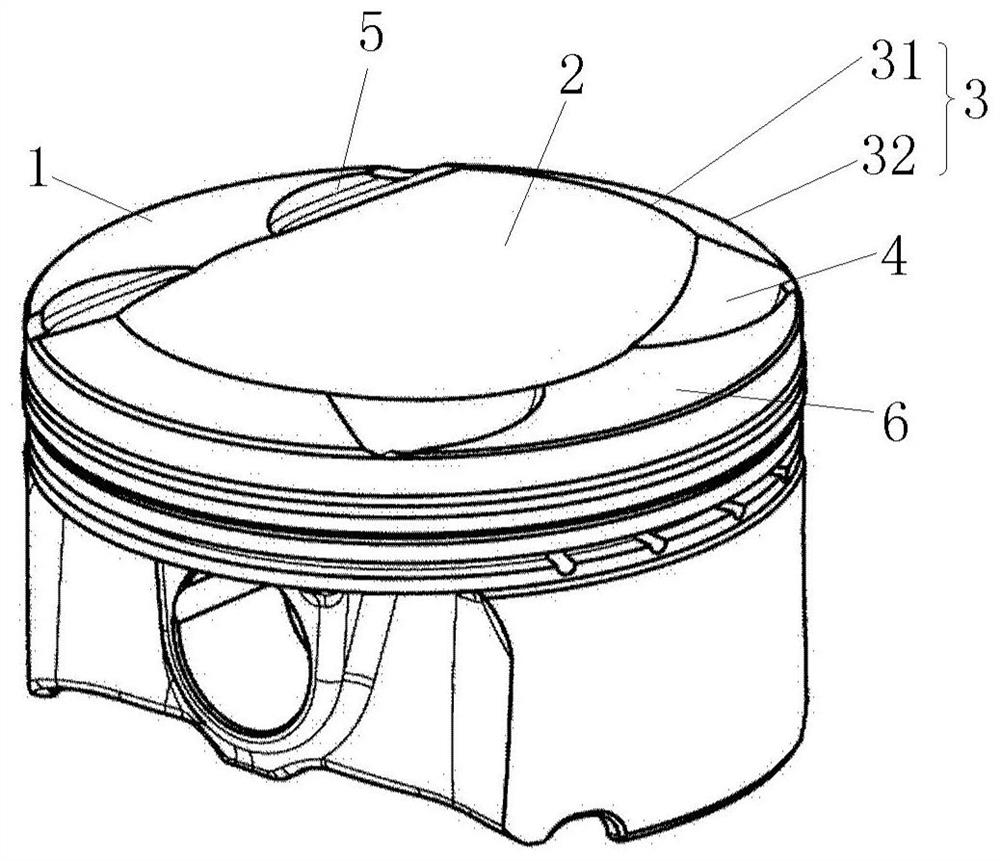

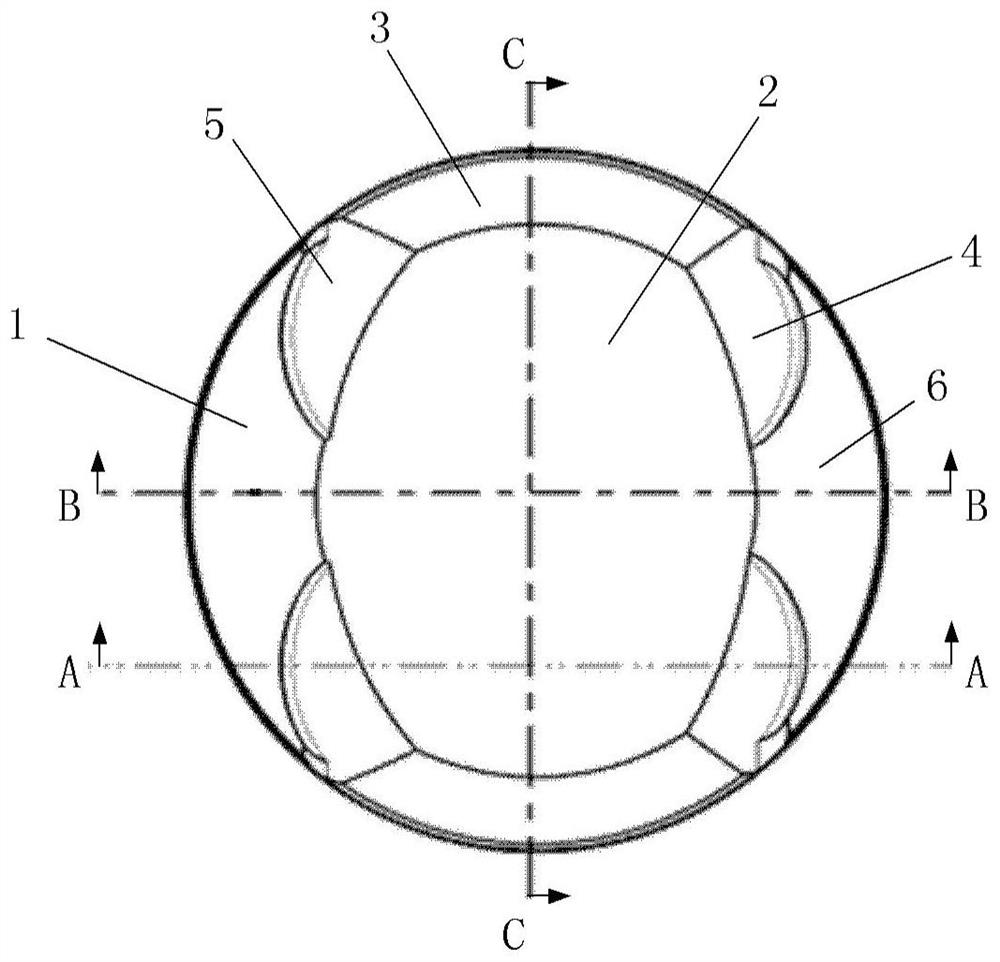

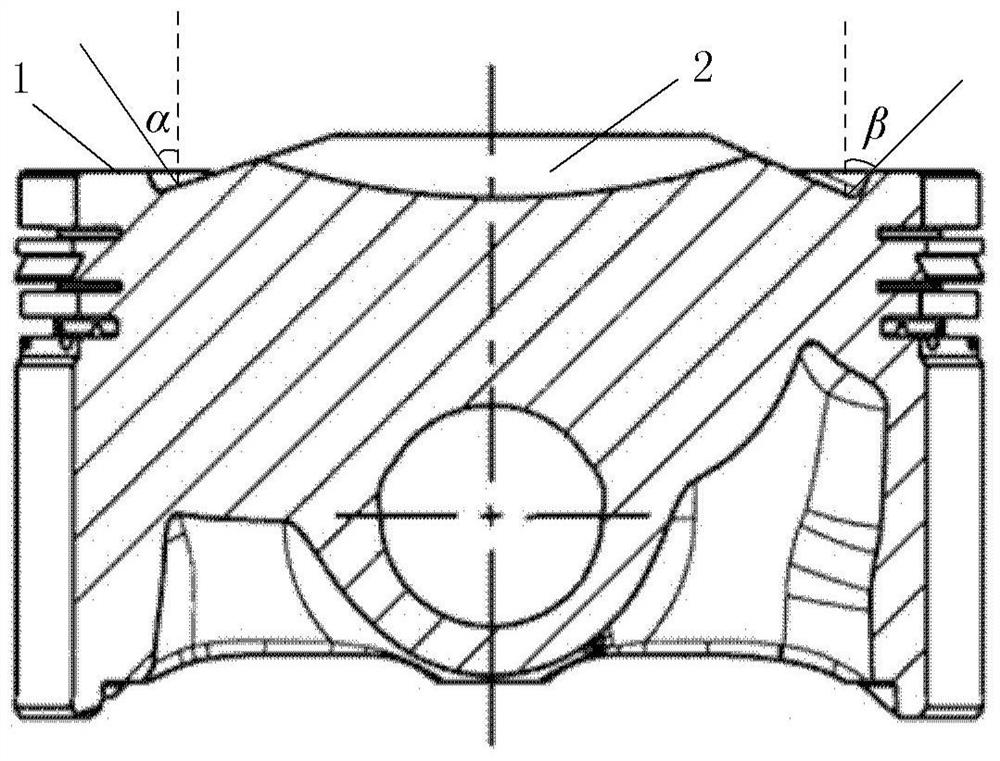

[0065] The disclosure provides an arc-top piston top, an arc-top piston and a combustion chamber. The arc-top piston top includes: an arc-shaped concave area and two conical convex areas. The arc-shaped pit area is a bowl-shaped pit located at the center of the top of the arc-top piston; the height of the first end of the conical raised area is higher than that of the second end of the conical raised area, One end is in contact with the outer edge of the arc-shaped pit area, and the second end of the tapered raised area extends to the edge of the top of the arc-top piston; the two tapered raised areas are respectively located on the front side of the arc-shaped pit area and The rear side, and the two conical convex areas are symmetrically arranged relative to the arc-shaped concave area. The arc-top piston top can be applied to engines with large bores and high compression ratios, which can increase the airflow velocity in the intake stroke of the engine to a large extent, inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com