Turbo-type vertical shaft wind mill

A turbine type and wind turbine technology, applied in the field of wind energy utilization, can solve the problems of easily damaged blades, and achieve the effects of improving wind energy utilization efficiency, improving wind gathering performance, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

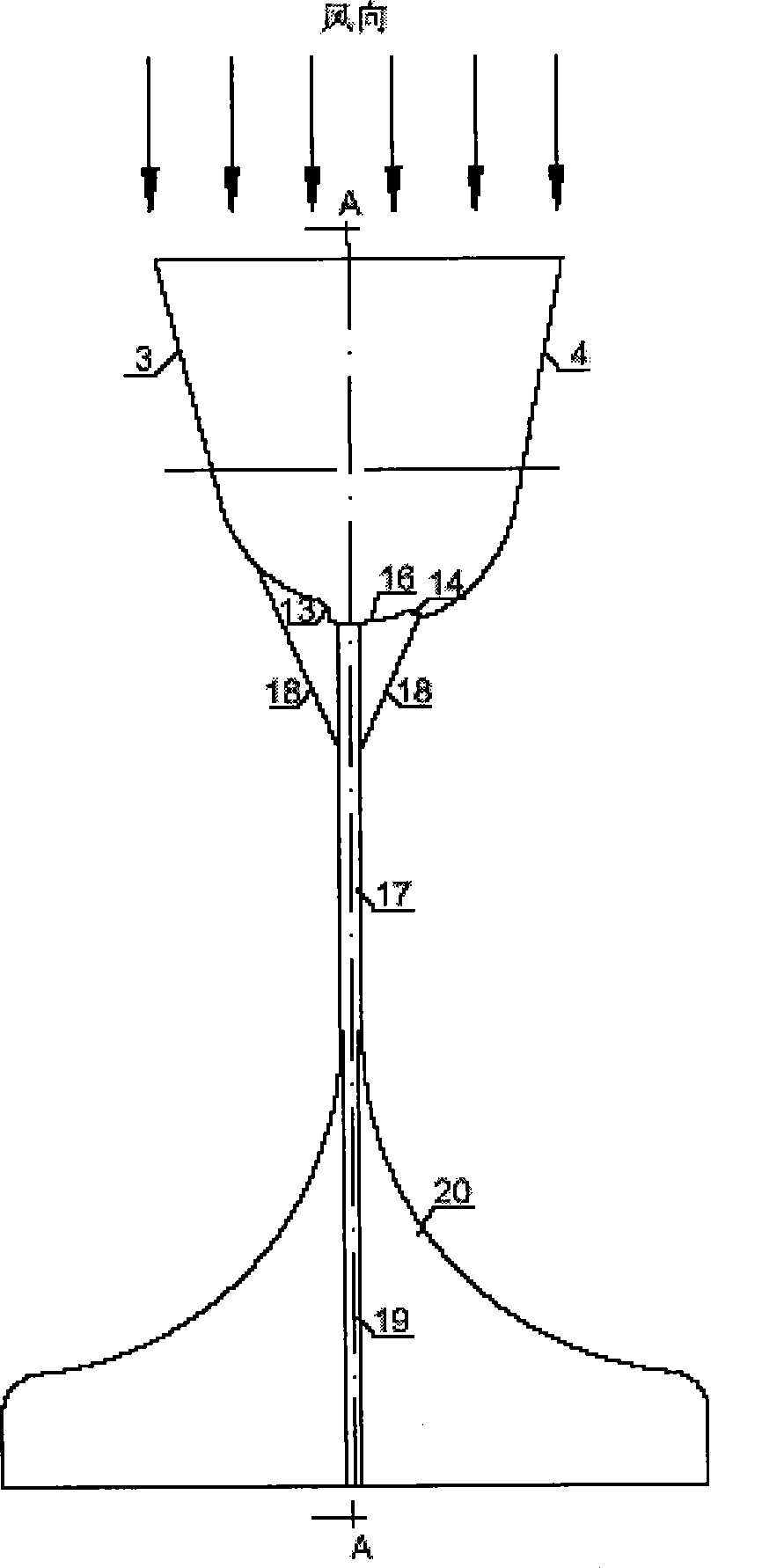

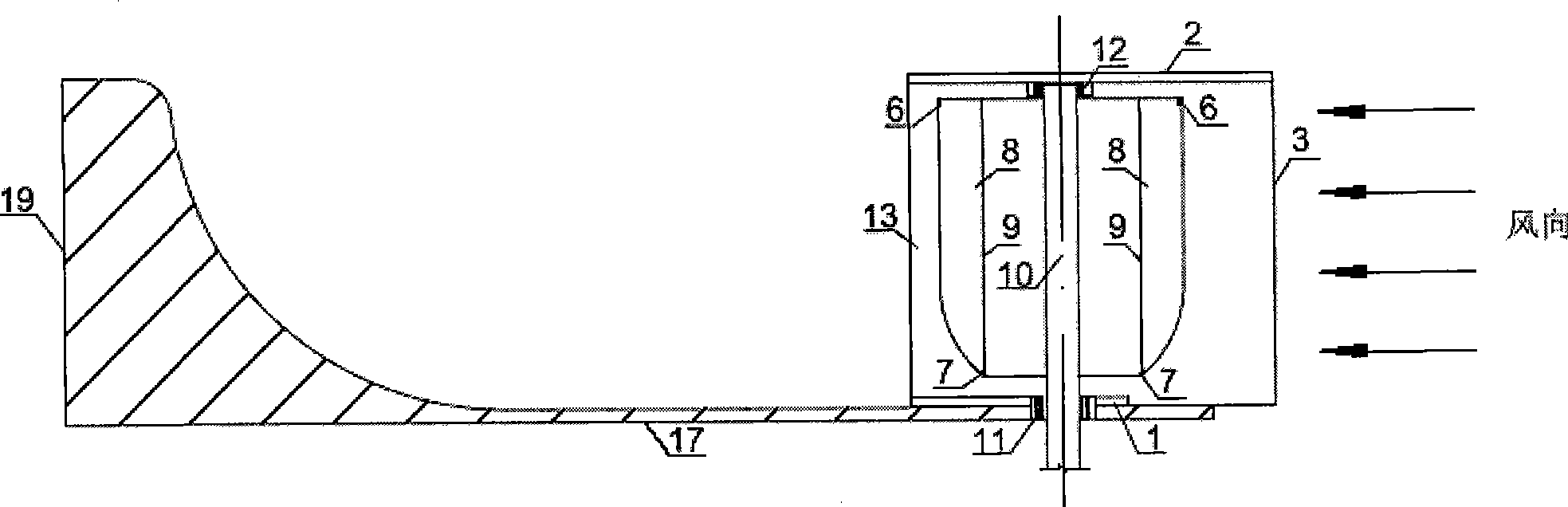

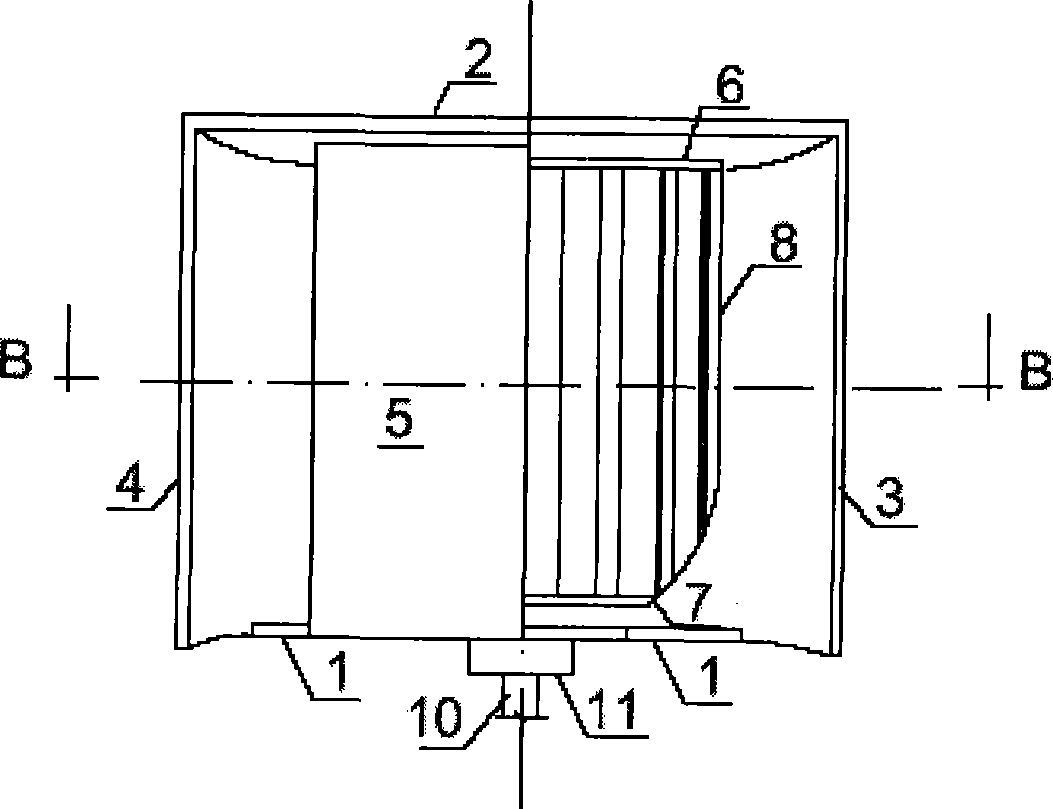

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0018] The turbine-type vertical axis wind power machine of the present invention is mainly composed of the wind collector bottom plate 1, the wind collector top plate 2, the left wind collector plate 3, the right wind collector plate 4, the volute 5, the blade upper hoop 6, the blade lower hoop 7, Blade 8, blade inner cylinder 9, shaft 10, wind collector bearing 11, impeller bearing 12, left wind collector tail fin 13, right wind collector deflector 14, right air inlet 15, wind collector outlet 16, Guide rod 17, guide rod support 18, vertical guide tail 19 and lateral guide tail 20 form. The upper blade hoop 6, the lower blade hoop 7 and the blade 8 are welded to form the impeller; the shaft 10 of the impeller is installed vertically, connected with the air collector bottom plate 1 through the wind collector bearing 11, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com