Mine air return port supercharging device and using method thereof

A technology of pressurization equipment and air return outlet, which is applied in mining equipment, mine/tunnel ventilation, mechanical equipment, etc., can solve the problems of simple and low efficiency of wind power utilization rate and cumbersome dust treatment at the mine return air outlet, so as to improve the filtration effect and The effect of lifespan, improving health and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

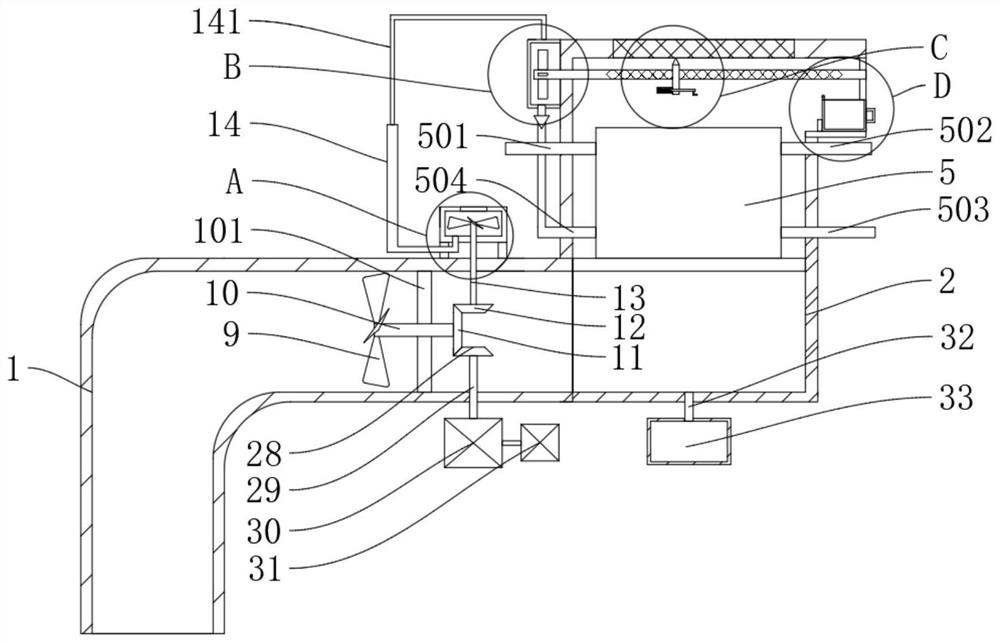

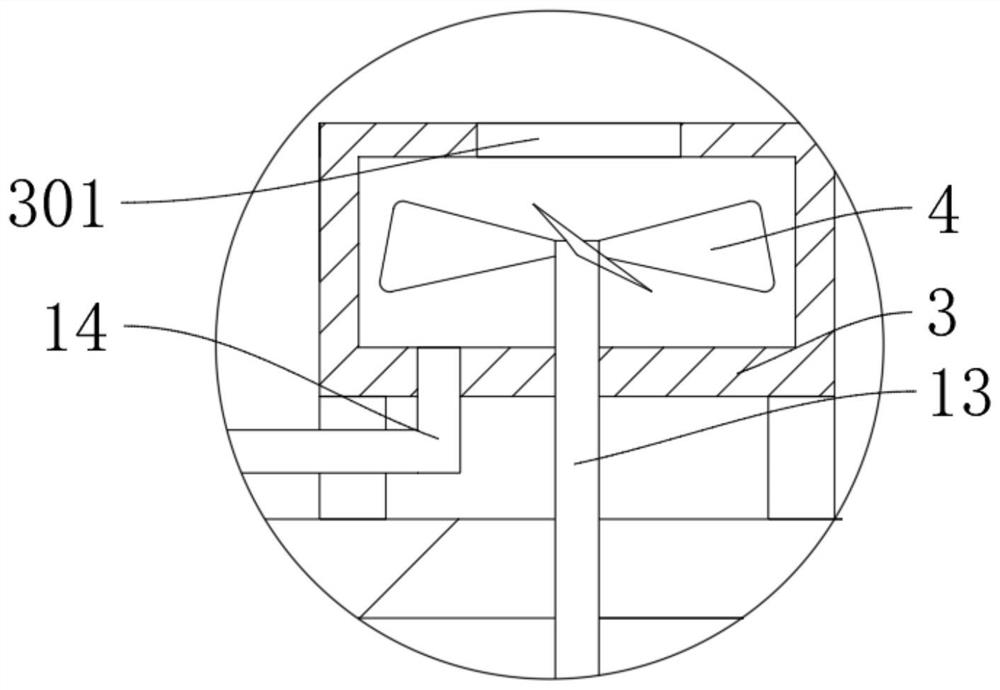

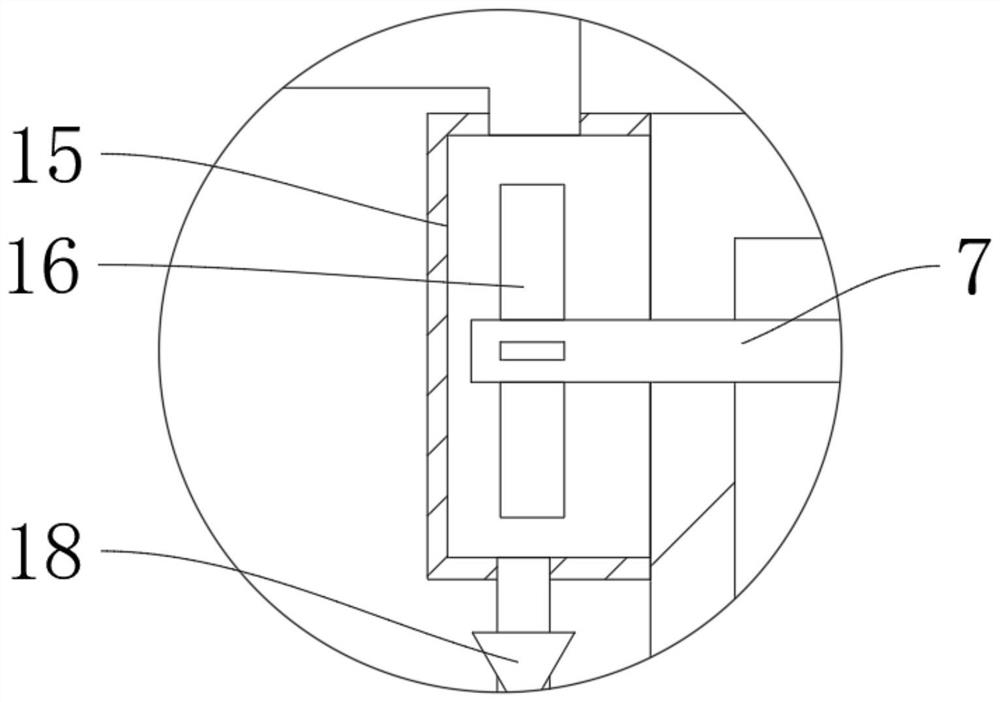

[0035] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , a kind of pressurization equipment for a mine air return port, comprising a return air pipe 1, a casing 2 and a heat exchanger 5, the return air pipe 1 is fixedly connected to the casing 2, the heat exchanger 5 is fixedly connected to the casing 2, and the return air The tube 1 is fixedly connected with a turbine box 3, the turbine box 3 is connected with the heat exchanger 5, the turbine blade 4 is rotatably connected with the turbine box 3, the filter plate 6 is fixedly connected with the box body 2, and the box body 2 is rotatably connected with a The screw mandrel 7 is provided with a reciprocating chute 701 , the reciprocating chute 701 is slidably connected with a dust removal plate 8 , and the return air duct 1 is fixedly connected with a driving mechanism, which is connected to the turbine blade 4 in rotation.

[0036] The driving mechanism includes a drive fan 9, a ...

Embodiment 2

[0045] refer to figure 1 , Figure 4 , a kind of mine air return port pressurization equipment and using method thereof, comprising return air duct 1, box body 2 and heat exchanger 5, return air duct 1 is fixedly connected with box body 2, heat exchanger 5 is fixedly connected with box body 2 Above, the return air pipe 1 is fixedly connected with a turbine box 3, the turbine box 3 is connected with the heat exchanger 5, the turbine blade 4 is rotatably connected with the turbine box 3, the filter plate 6 is fixedly connected with the box body 2, and the box body 2 The screw rod 7 is rotatably connected to the screw rod 7, and a reciprocating chute 701 is provided on the screw rod 7, and the dust removal plate 8 is slidably connected to the reciprocating chute 701, and a driving mechanism is fixedly connected to the return air pipe 1, and the driving mechanism is connected to the turbine blade 4 in rotation. .

[0046] The driving mechanism includes a drive fan 9, a first rot...

Embodiment 3

[0055] refer to figure 1 , Figure 4 , Figure 5 , Figure 6 , a kind of mine air return port pressurization equipment and using method thereof, comprising return air duct 1, box body 2 and heat exchanger 5, return air duct 1 is fixedly connected with box body 2, heat exchanger 5 is fixedly connected with box body 2 Above, the return air pipe 1 is fixedly connected with a turbine box 3, the turbine box 3 is connected with the heat exchanger 5, the turbine blade 4 is rotatably connected with the turbine box 3, the filter plate 6 is fixedly connected with the box body 2, and the box body 2 The screw rod 7 is rotatably connected to the screw rod 7, and a reciprocating chute 701 is provided on the screw rod 7, and the dust removal plate 8 is slidably connected to the reciprocating chute 701, and a driving mechanism is fixedly connected to the return air pipe 1, and the driving mechanism is connected to the turbine blade 4 in rotation. .

[0056] The driving mechanism includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com