Laundry Tablet Slurry Vortex Channel Stirring and Mixing Device

A technology of mixing and washing tablets, which is applied to mixers with rotating stirring devices, mixers, transportation and packaging, etc., which can solve the problems of low automation, low work efficiency, low mixing efficiency, and high labor intensity. Achieve the effect of improving mixing efficiency, high reliability and large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

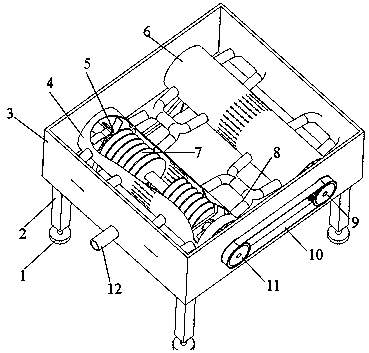

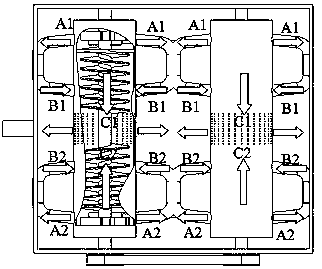

[0014] control figure 1 , 2 Before working, the operator needs to check the connection of each component and whether the state of the device is stable and reliable, so as to avoid safety accidents during work, close the discharge pipe 12, and the staff will pour the raw materials and water of the active ingredients of the laundry sheet into the material. In the box 3, and pour from different positions of the material box 3 as much as possible, to shorten the initial mixing time and reduce the initial mixing resistance, so far the device has completed the preparation work.

[0015] During work, external power transmits power to synchronous pulley one 11, and described synchronous pulley one 11 transmits power to synchronous pulley two 9 by synchronous belt 10, is connected with synchronous pulley one 11 and synchronous pulley two 9 It is the pusher screw shaft 7, and the paddle 5 is installed on the pusher screw shaft 7. The paddle 5 and the pusher screw shaft 7 are both in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com